Synthetic method of organosilicon polyurethane-acrylic ester ternary composite ionomer emulsion

An acrylate and ternary composite technology, which is applied in the field of synthesis of silicone-polyurethane-acrylate ternary composite ionomer emulsions, can solve the problems that ionomer emulsions are rarely reported, and achieve enhanced water resistance and performance Stable and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Below is the example of silicone-polyurethane-acrylate ionomer emulsion prepared by the present invention, which has the following process and steps:

[0027] (1) Synthesis of silicone polyurethane prepolymer

[0028] Mix 90ml of methyl ethyl ketone solvent with 0.1mol of toluene diisocyanate (TDI) and add it to a three-necked flask protected by nitrogen, and drop three drops of catalyst dibutyltin dilaurate (DBT), raise the temperature to 60°C, and slowly drop Add hydroxyl-terminated polydimethylsiloxane, the content of hydroxyl-terminated polydimethylsiloxane accounted for 22% by mass of toluene diisocyanate, drop it in about 1.5h, and continue to react for 1.5 hours after the dropwise addition. Then polyisopropylene glycol (PPG1000) was added dropwise, the molar ratio of toluene diisocyanate (TDI) to polyisopropylene glycol was 1:1, the drop was completed in about 1.5h, and the reaction was continued for 1.5 hours after the dropwise addition.

[0029] (2) Synthesis ...

Embodiment 2

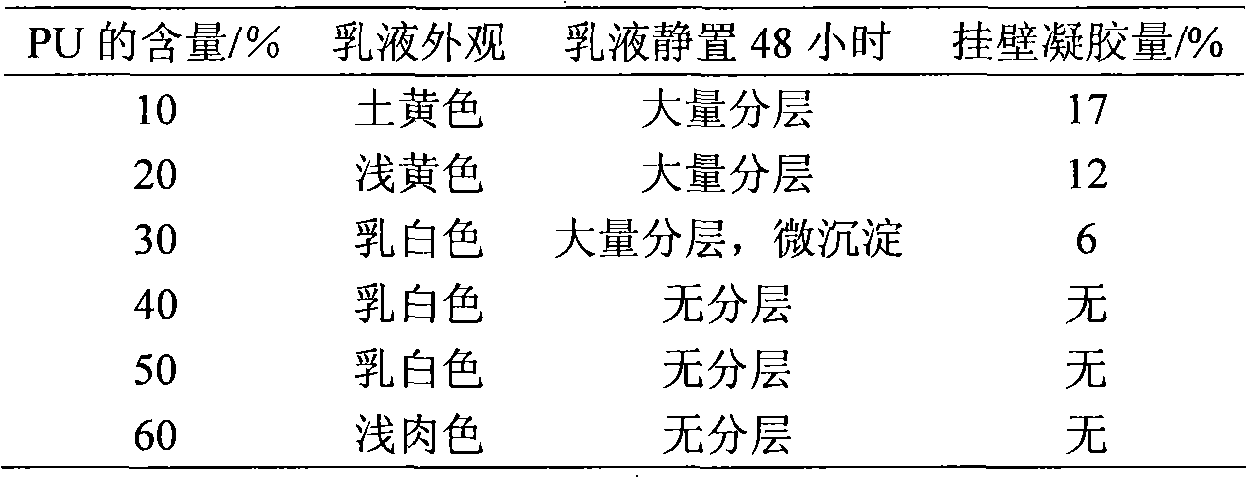

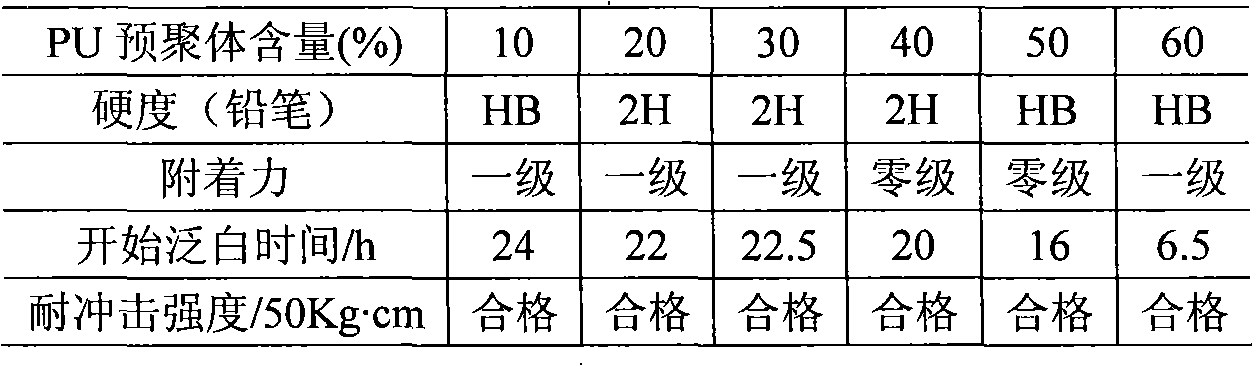

[0034] The synthesis method of the silicone-polyurethane-acrylate ternary composite ionomer emulsion of this embodiment is basically the same as that of Example 1, except that the mass percentage of cationic silicone polyurethane prepolymer (PU) is shown in Table 1. The impact of different cationic silicone polyurethane prepolymer (PU) mass percentages on the properties of the copolymer emulsion is listed. It can be seen from the table that the color of the emulsion becomes lighter with the increase of the PU content, and the amount of gel in the copolymerization reaction decreases. Copolymer emulsions are also more stable. Because PU prepolymer contains a large number of ionic bonds and contains hydrophilic and lipophilic groups, it can play a good emulsifying effect on emulsion polymerization. Therefore, the increase of PU content is helpful to the emulsion polymerization reaction, so the synthesized emulsion is more stable and the amount of gel is reduced, which plays the r...

Embodiment 3

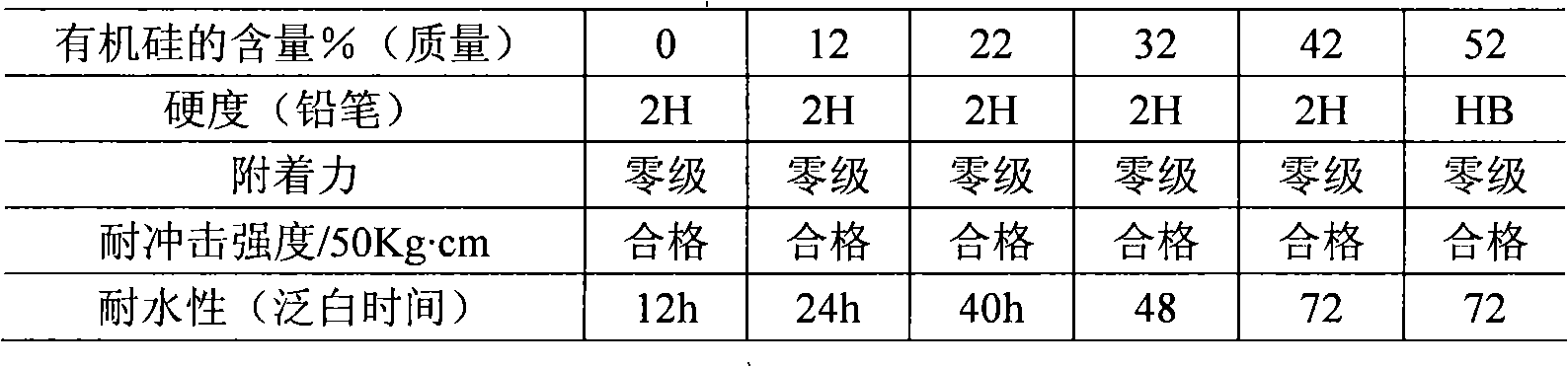

[0041] The synthetic method of the organosilicon-polyurethane-acrylate ternary composite ionomer emulsion of the present embodiment is basically the same as that of Example 1, except that the mass percentage of organosilicon is listed in Table 3. The effect of changes on the mechanical properties of the coating film. It can be seen from the table that the mechanical properties of the coating film have been greatly improved. The hardness of the coating film can reach 2H when the organic silicon content is less than 52%, the adhesion can reach zero grade, and the impact resistance strength is all qualified. Analysis of the water resistance data of the coating film shows that the water resistance of the coating film has been greatly improved through the ionic bonding between acrylate and polyurethane. At the same time, with the increase of the silicone content, the water resistance of the coating film has also been enhanced.

[0042] Table 4 lists the effects of changes in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com