Multipurpose coal liquefaction device and coal liquefaction process

A coal liquefaction and process technology, applied in the field of multi-purpose coal liquefaction devices, can solve problems such as difficult changes in raw materials and product solutions, incompatibility of processes and devices, cumbersome processing procedures, etc., to reduce material diffusion resistance, improve liquid product yield, Avoid secondary cracking and condensation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

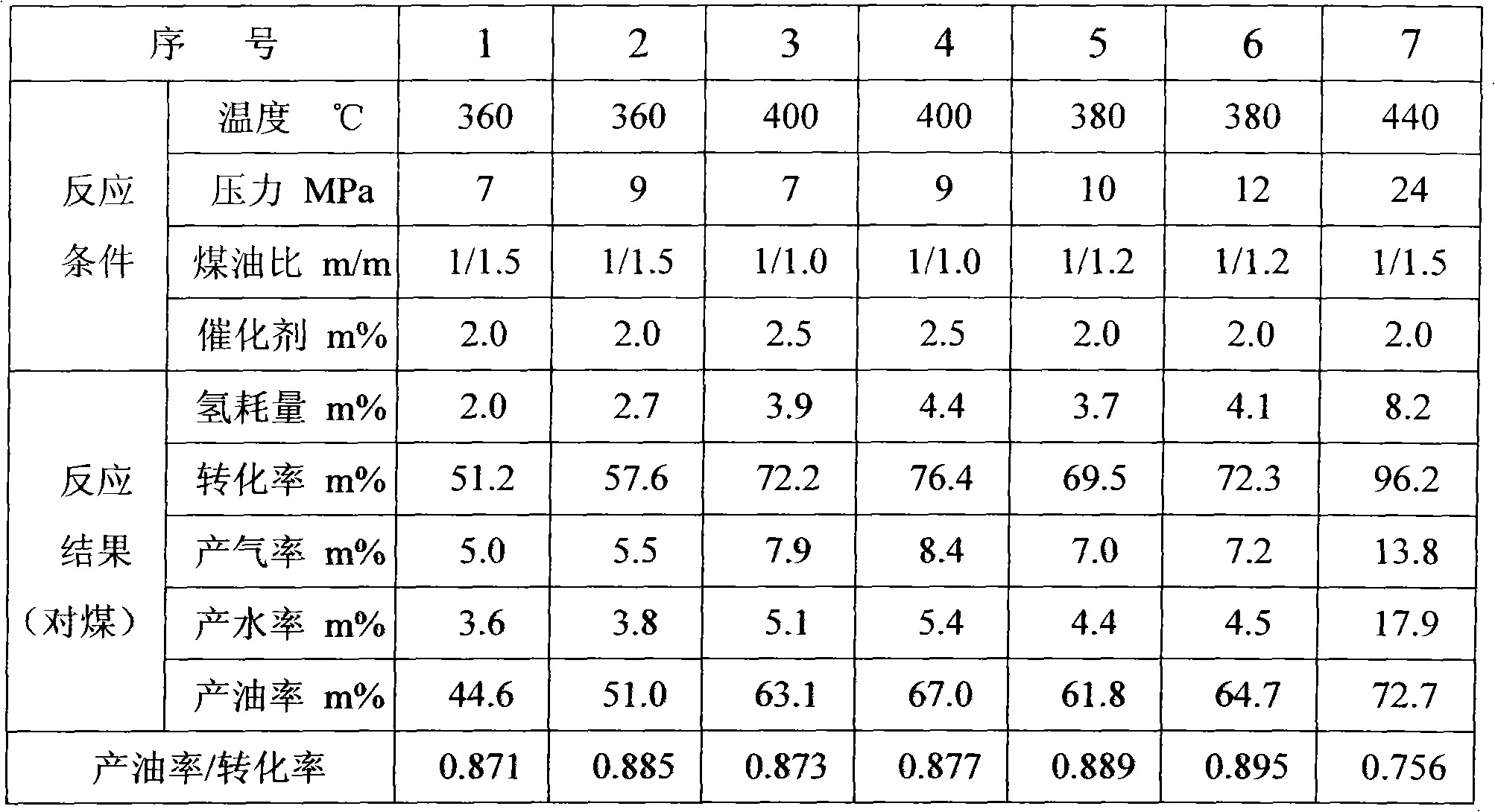

[0037] A highly dispersed iron-based catalyst treated with a colloid mill, containing 65.4m% FeS 2 , 5.7m% Fe 2 o 3 , 11.3m% FeSO 4 , 11.5m% AL 2 o 3 and 6.1m% SiO 2 , the dosage is 1.8m% (for coal), and the residual oil at >400°C is used as the solvent to carry out the hydrogen kerosene co-refining test on 100 mesh lignite, the hydrogen purity is 96v%, and the feed space velocity is 1.0h -1 , raw material hydrogen to solid-liquid volume ratio 300(Nm 3 / m 3 ). The test results are shown in Table 1. The fraction composition of the liquefied oil corresponding to the test number is shown in Table 2.

[0038] Table 1

[0039]

[0040] The reaction results shown in Table 1 are for anhydrous and ash-free coal. The liquefied oil is distilled and analyzed. When the distillation temperature is higher than 360 ° C, the liquefied oil begins to have decomposed water, and the liquefied oil with a low reaction temperature decomposes water. Slightly more, the liquefied oil reac...

Embodiment 2

[0057] An improved liquid catalyst is used, the active ingredients are dimer acid urea complexed lanthanum 3.5m%, ethylenediaminetetraacetic acid complexed iron 6.8m%, glutaric acid urea complexed cobalt 5.6m%, isooctanoic acid urea complexed 1.8m% molybdenum, 2m% sorbitan monooleate as auxiliary agent, and residue oil at >400°C as solvent. 100% screened 100-mesh lignite was tested for low-pressure solvent hot-melt catalysis, the hydrogen purity of stirring was 96v%, and the feeding space velocity was 1.0h -1 , stirring hydrogen to solid-liquid volume ratio 100 (Nm 3 / m 3 ). In addition, the patent 200410015698.0 was implemented in an autoclave for comparison. The test results are shown in Table 3.

[0058] The reaction results shown in Table 3 are for anhydrous and ash-free coal. The pressure of the test of the present invention is automatically controlled by the hydrogen pressure, and the pressure of the control test is firstly filled with nitrogen to pressurize the aut...

Embodiment 3

[0069] A liquid catalyst containing 15.2m% of potassium aluminate, 8.5m% of potassium vanadate, 15.5m% of ferrous sulfate, 6.8m% of ammonium molybdate, 5.4m% of nickel nitrate and 35m% of acetic acid aqueous solution is used as the liquid catalyst. The dosage is 2.5m% (to coal), with industrial xylene: benzene: water = 60: 30: 10 (weight ratio) as solvent, adding 0.25m% (to solvent) sodium dodecylsulfonate as auxiliary agent Carry out the extraction test of 100% screening 100 order lignite on the device of the present invention, temperature 420 ℃, pressure 18MPa, the mixed gas that hydrogen and CO volume ratio are 1: 1 is stirring gas and hydrogenation gas, coal agent weight ratio =1:5, gas to solid-liquid volume ratio 150(Nm 3 / m 3 ), airspeed 1.0h -1 . In addition, a comparative test was carried out on an autoclave, with the same solvent and coal agent ratio, no catalyst and additives added, nitrogen pressure at 18MPa, heating at 50°C / h to 420°C for 1h at constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com