Carboxylation method of polyoxyethylene-poly-oxypropylene polyoxyethylene copolymer

A polyoxyethylene and polyoxypropylene technology, applied in the field of polymer materials, can solve the problems of ether bond breakage, violent reaction, inconvenient cost, etc., and achieve the effects of mild conditions, simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

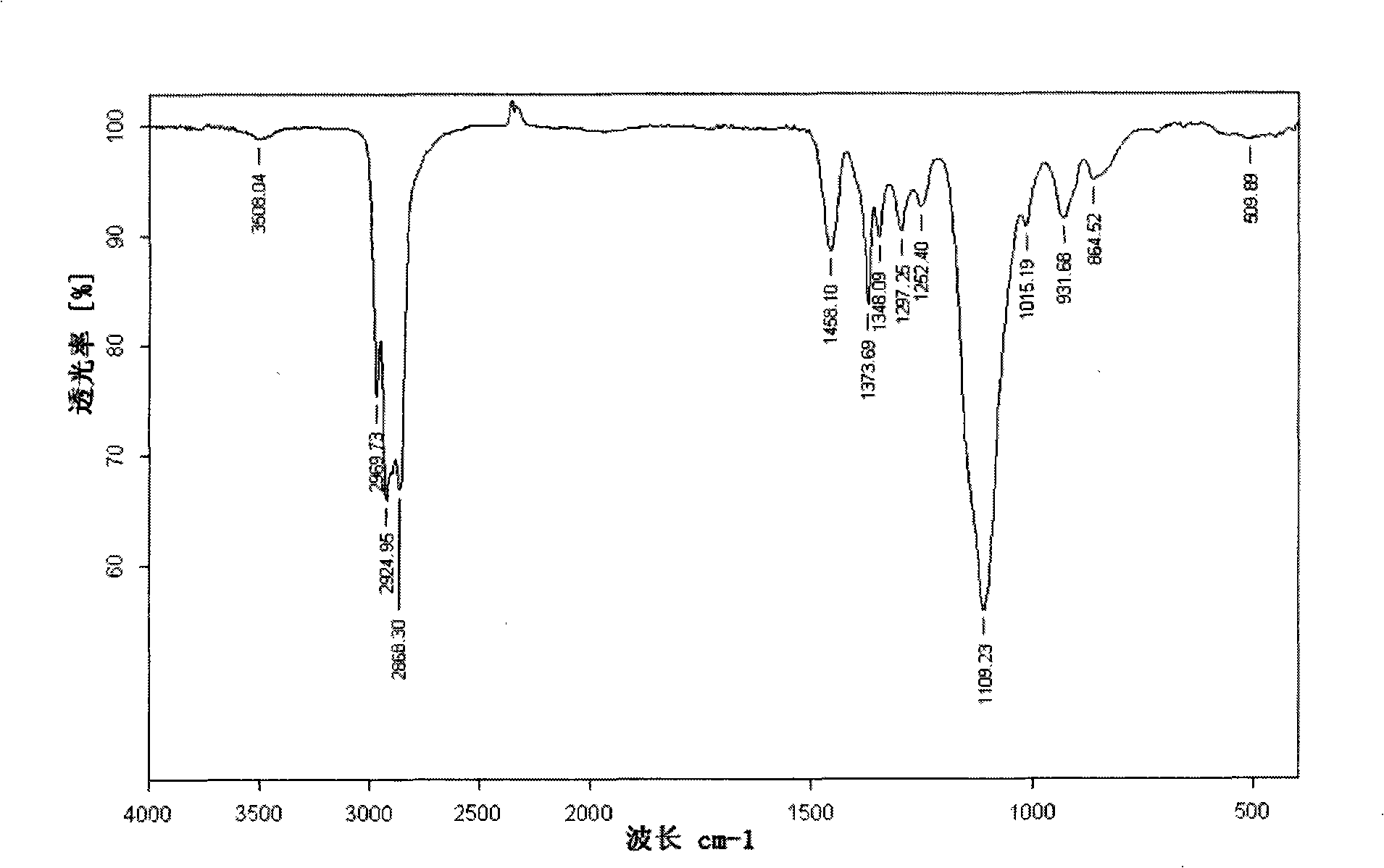

Embodiment 1

[0041]Weigh 2g P123 type PEO-PPO-PEO block copolymer, stir and dissolve with 30mL pure water, then add an appropriate amount of 40% potassium hydroxide solution while stirring, keep the temperature of the reaction solution at 2±0.5°C, add 5mL dropwise while stirring Acrylonitrile, continue to stir (200rpm) to react for 24h, adjust the pH value to neutral with concentrated hydrochloric acid after the reaction is completed, use an equal volume of dichloromethane to extract the addition reaction product solution, add anhydrous sodium sulfate and let it stand overnight to absorb all the impurities in the extract. Contain water, filter, and the filtrate is evaporated in a water bath at 50°C to remove the solvent, and dried in vacuum overnight to remove the solvent to obtain the addition product;

[0042] Dissolve the addition product in 20mL of 2M sodium hydroxide solution, reflux in an oil bath at 105°C for 6 hours, adjust the pH of the reaction product solution to 2 with concentra...

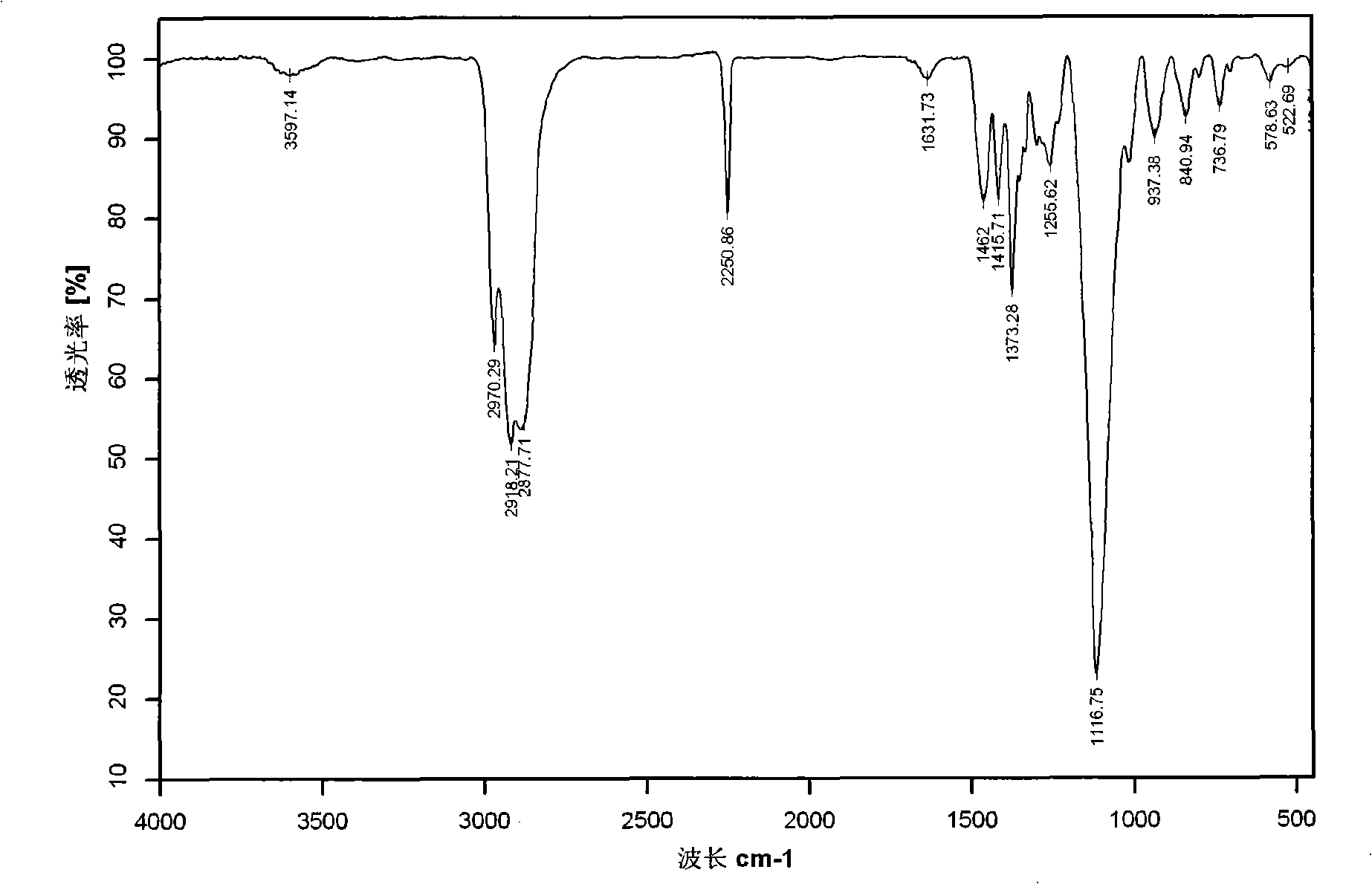

Embodiment 2

[0046] Weigh 2g of F127 type PEO-PPO-PEO block copolymer, dissolve it with 20mL of pure water ultrasonically, add an appropriate amount of 50% potassium hydroxide solution while stirring, keep the temperature of the reaction solution at 0±0.5℃, add 2mL dropwise while stirring Acrylonitrile, continue to stir (100rpm) to react for 48h, after the reaction, adjust the pH value to neutral with concentrated hydrochloric acid, use an equal volume of dichloromethane to extract the addition reaction product solution, add anhydrous sodium sulfate and let it stand overnight to absorb all the impurities in the extract. Contain water, filter, and the filtrate is evaporated in a water bath at 40°C to remove the solvent, and dried in vacuum overnight to remove the solvent to obtain the addition product;

[0047] Dissolve the addition product in 40mL of 1M potassium hydroxide solution, reflux in an oil bath at 105°C for 7 hours, adjust the pH value of the reaction product solution to 4 with co...

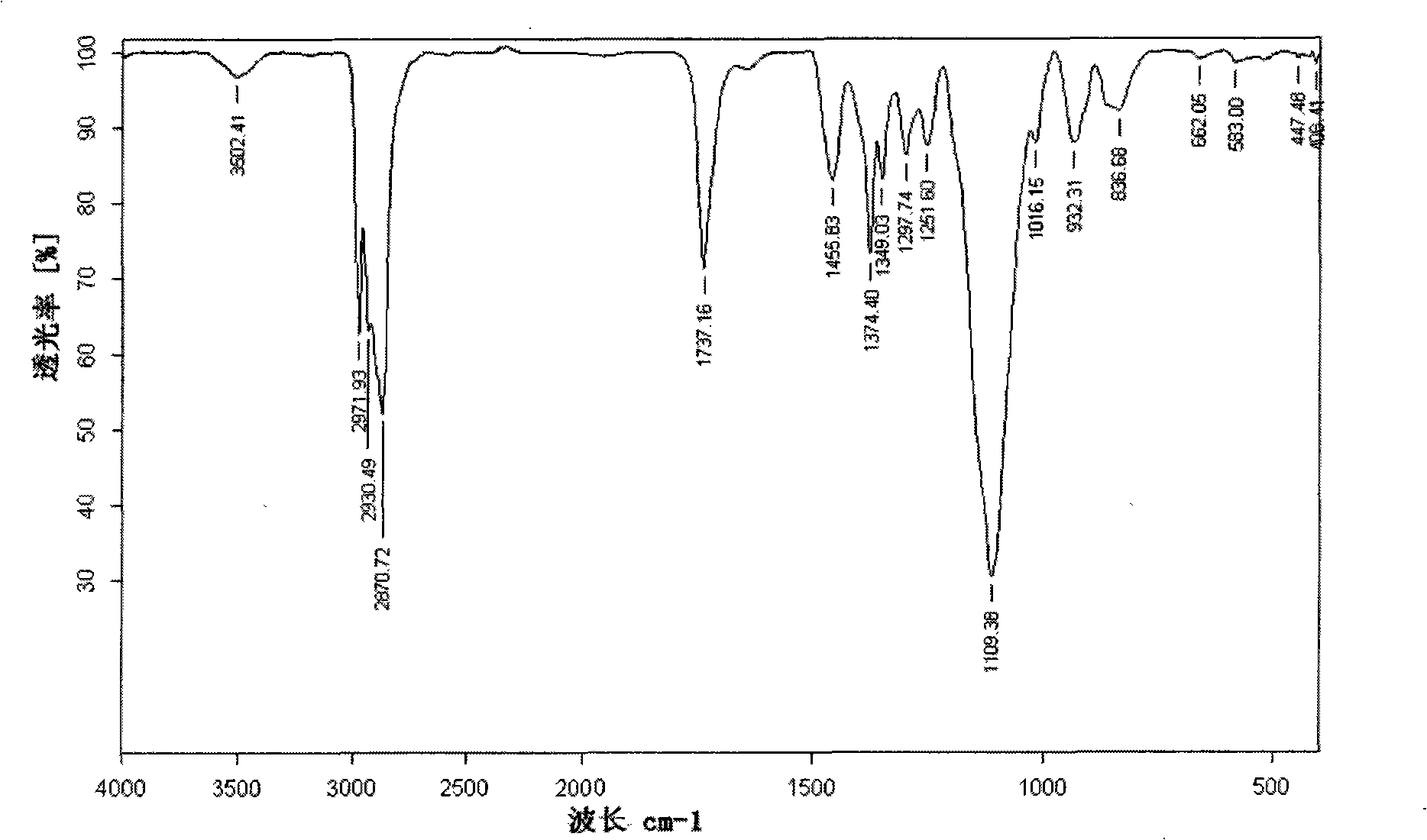

Embodiment 3

[0050] Weigh 2g of P123 type PEO-PPO-PEO block copolymer, stir and dissolve with 20mL of pure water, then add an appropriate amount of 20% potassium hydroxide solution while stirring, keep the temperature of the reaction solution at 4±0.5°C, add 5mL dropwise while stirring Acrylonitrile, continue to stir (200rpm) to react for 24 hours, after the reaction, adjust the pH value to neutral with concentrated hydrochloric acid, 60 ° C water bath rotary evaporation to dry the solvent, 40 ° C vacuum drying overnight, add chloroform to extract the residue, filter, the filtrate Evaporate in a water bath at 50°C to dry the solvent, dry it in vacuum overnight to remove the solvent, and obtain the addition product;

[0051] Dissolve the addition product in 20 mL of 2M sodium hydroxide solution, stir and react at 200 rpm for 7 days, adjust the pH value of the reaction product solution to 3 with concentrated hydrochloric acid, evaporate the solvent in a water bath at 60°C, and dry it under va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com