Improved carbon nanotube based semiconducting devices and methods for their production

A technology of carbon nanotubes and nanotubes, which is applied in the field of improved photovoltaic devices or light-emitting devices, can solve the problems of prolonged exposure, deterioration of absorption and/or emission characteristics, etc., and achieve the goals of prolonging device life, good operational stability, and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

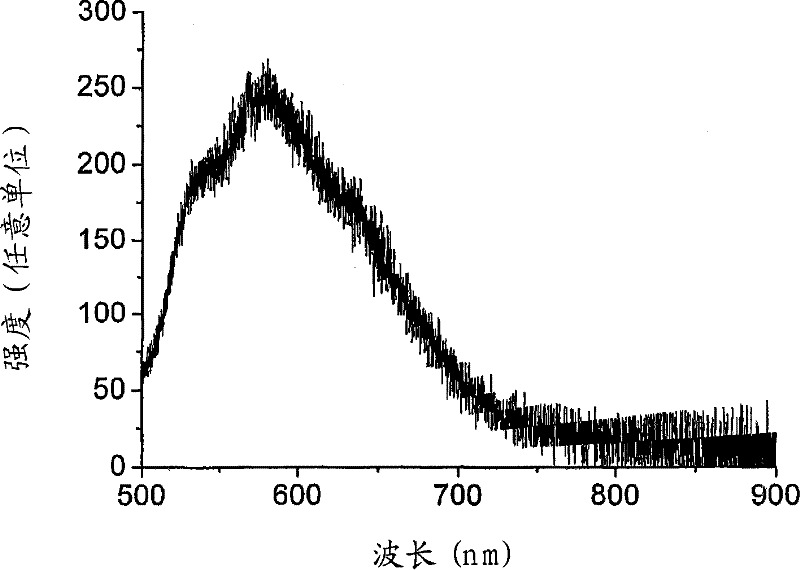

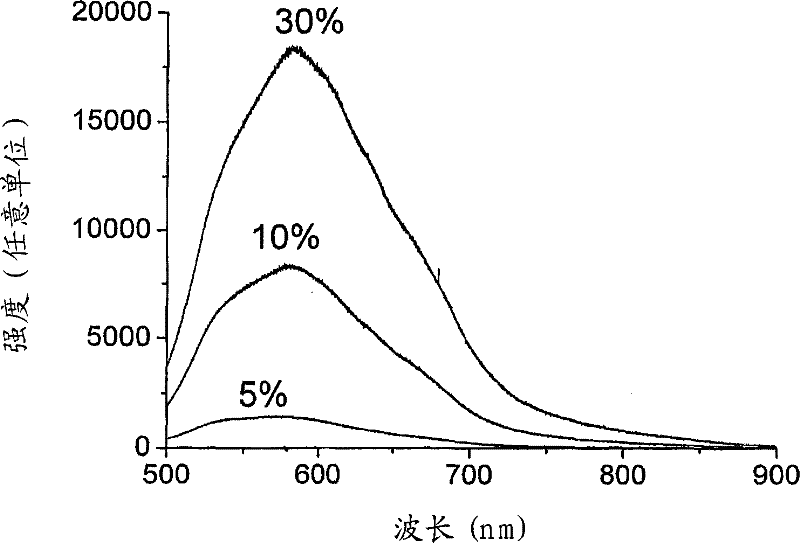

[0059] In this embodiment, tuned carbon nanotubes embedded in an organic matrix are excited into electronically excited states by coherent visible and ultraviolet light. It should be noted, however, that in the present invention, photoexcitation of tuned carbon nanotubes can be achieved using coherent light (such as laser light) and / or incoherent light (such as sunlight). The photoexcited carbon nanotubes then transfer the excitation energy, at least a portion of it, to emissive centers in the organic matrix, which then return to the ground state upon emission of visible light. In this embodiment, the energy of light emitted by the organic host matrix is lower than the energy absorbed by the tuned carbon nanotubes. That is, in this embodiment, the tuned composite of carbon nanotubes and organic matrix is used as a downconverter for UV and visible light.

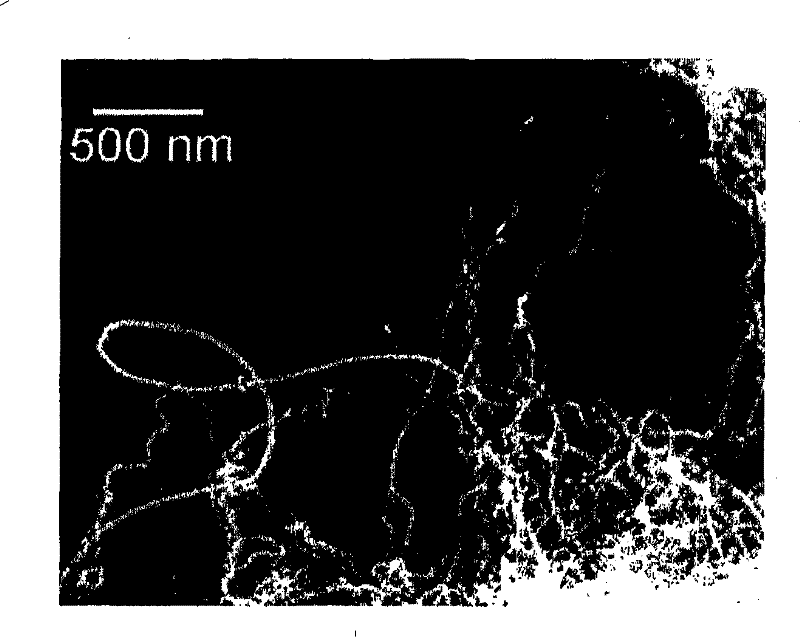

[0060] To fabricate composites in which carbon nanotubes are dispersed in a matrix of organic materials requires sever...

no. 2 approach

[0077] Utilize the present invention to make organic solar cells:

[0078] Organic solar cells include one or more semiconducting organic thin films sandwiched between two electrodes. Each film may comprise a single material or a composite of two or more different materials.

[0079] Figure 12A A schematic diagram of a heterojunction organic solar cell device according to the present embodiment is shown. The device includes a transparent anode 301 made of indium tin oxide (ITO) coated glass with a sheet resistance of less than 100 ohms / square. The ITO coating on the glass substrate is usually 100nm-300nm thick. It should be understood that any translucent conductive substrate can be used as a transparent electrode, including conductive polymer-carbon nanotube composites such as poly(3,4-ethylenedioxy-2,4-thiophene)-polyphenylene Ethylene sulfonate (PEDOT:PSS)-MWCNT composites in which a continuous network of MWCNTs in a conductive polymer film is used to enhance its elect...

no. 3 approach

[0087] As described in this embodiment mode, the present invention can also be used in organic light emitting diodes (OLEDs).

[0088] Organic light emitting diodes include one or more semiconducting organic films sandwiched between two electrodes. Each membrane may contain a single compound or a composite of two or more different compounds.

[0089] Figure 13A A schematic diagram of a multilayer OLED device according to the present embodiment is shown. The device includes a transparent anode 901 made of indium tin oxide (ITO) coated glass with a sheet resistance of less than 100 ohms / square. The ITO coating on the glass substrate is usually 100nm-300nm thick. Next to the transparent anode 901 are two organic layers: a hole transport layer 902 and an emitter layer 903 . In this embodiment, the emitter layer comprises a composite of tuned carbon nanotubes and an organic semiconductor. The device is completed by a low work function metal cathode 904 . An external power so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com