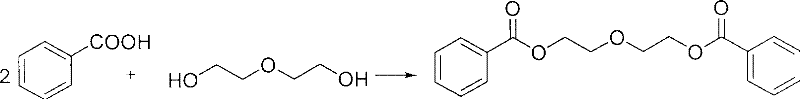

Preparation method of diethylene glycol dibenzoate

A technology of diethylene glycol dibenzoate and benzoic acid, which is applied in the field of preparation of diethylene glycol dibenzoate, can solve the problems of post-processing, troublesome operation, high reaction temperature and high product cost, and achieves post-processing The effect of simple process, low reaction temperature and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 1000g of benzoic acid and 430g of diethylene glycol into a 2L three-necked bottle, the feeding ratio is 2:1.05, heat up while stirring (oil bath temperature 180-200°C), add 20g of heteropoly acid as a catalyst, and then add Saturated hydrocarbon cyclohexane is used as 80g of water-carrying agent, the temperature is adjusted to 145-160°C, and the temperature is kept for 10-15h to complete the reaction. At a temperature of 145-160°C, the dehydration agent is decompressed to obtain the crude product DEDB, which is deacidified by calcium carbonate, sodium carbonate, alkaline resin or sodium hydroxide, and traditionally decolorized to obtain DEDB.

Embodiment 2

[0023] Put 1000g of benzoic acid and 480g of diethylene glycol into a 2L three-necked bottle, and the feeding ratio is 2:1.1, heat up while stirring (oil bath temperature 100~120°C), add 32g of hydrochloric acid as a catalyst, and then add saturated hydrocarbon Water-carrying agent cyclohexane 90g, keep warm for 6-8h, adjust the temperature to 90-100°C to complete the reaction. At this temperature, the hydrocarbon water-carrying agent is removed under reduced pressure to obtain the crude product DEDB, which is deacidified by calcium carbonate, sodium carbonate, alkaline resin or sodium hydroxide, and DEDB is obtained by traditional decolorization.

Embodiment 3

[0025] Put 1000g of benzoic acid and 480g of diethylene glycol into a 2L three-necked bottle, and the feeding ratio is 2:1.1, heat up while stirring (oil bath temperature 120-140°C), add 20g of hydrochloric acid and 8g of p-toluenesulfonic acid as Catalyst, then add 50g of n-hexane, a saturated hydrocarbon water-carrying agent, adjust the temperature to 90-100°C, and keep it warm for 1216h to complete the reaction. At this temperature, the hydrocarbon water-carrying agent is removed under reduced pressure to obtain the crude product DEDB, which is deacidified by calcium carbonate, sodium carbonate, alkaline resin or sodium hydroxide, and DEDB is obtained by traditional decolorization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com