Bacterial for optimizing abomacetin fermentation component, construction method and use

A technology of erythromycin and saccharopolysporidium mold, applied in the field of biotechnology engineering, can solve the problems of lack of effective pertinence, low effective components and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

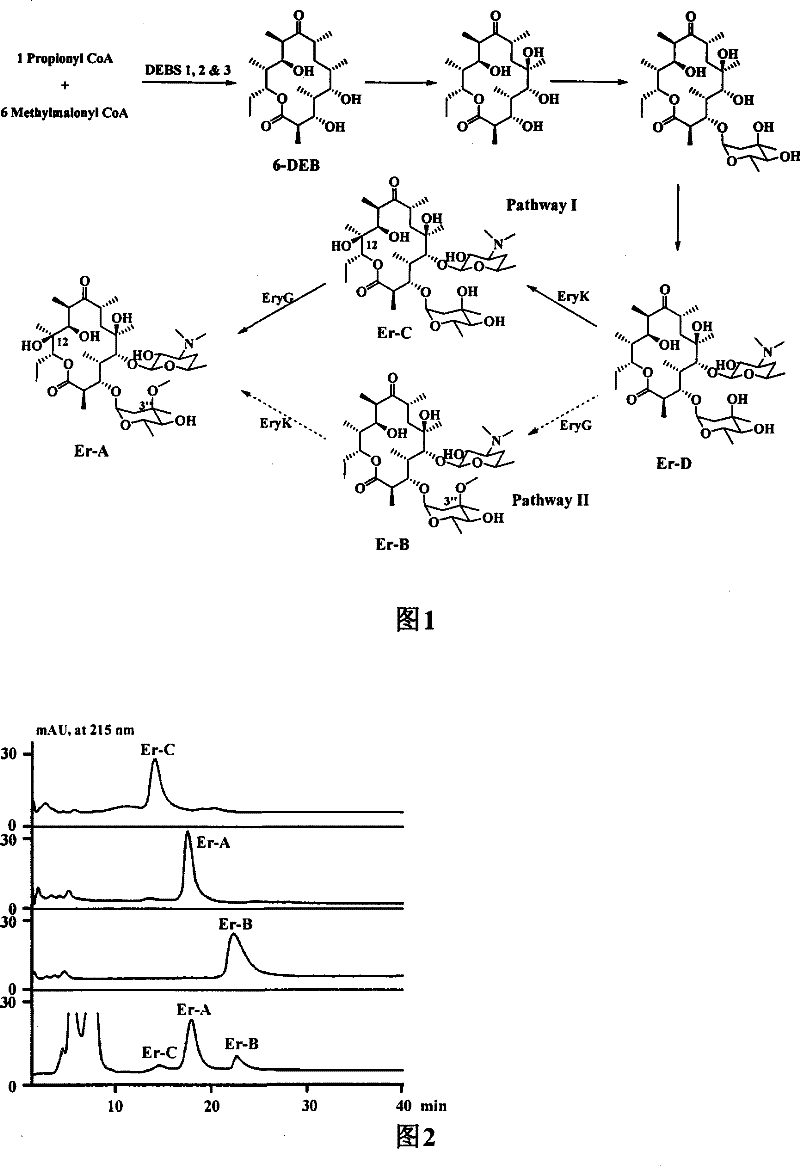

AI Technical Summary

Problems solved by technology

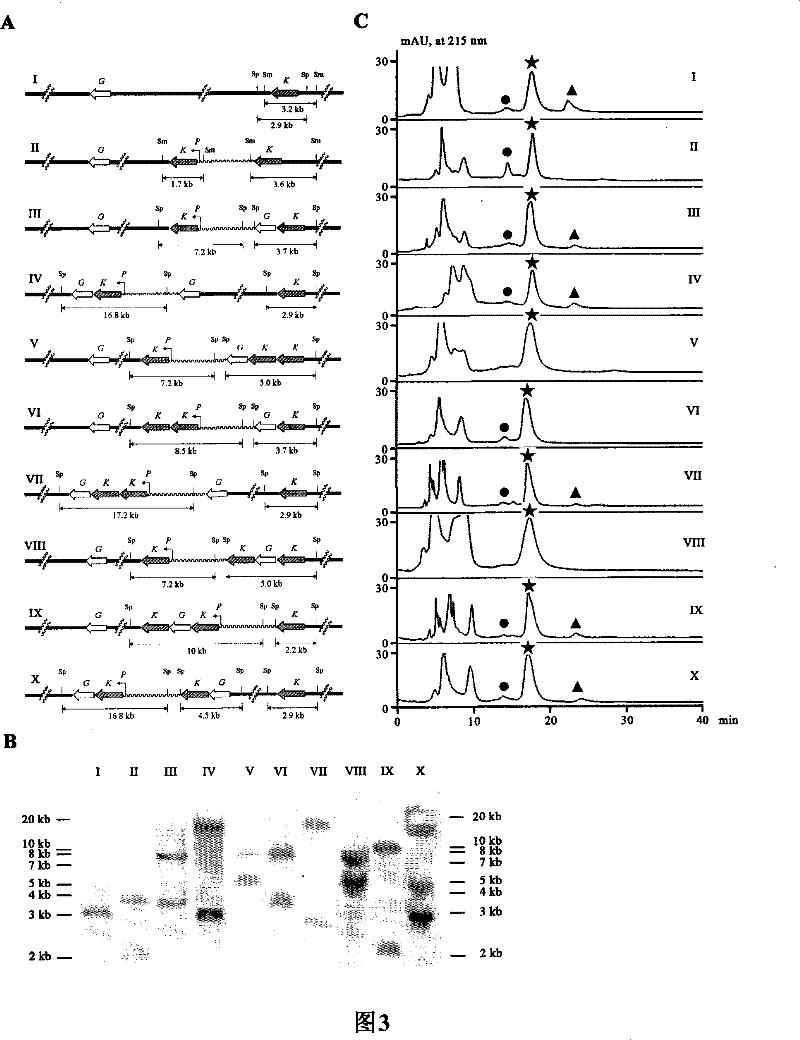

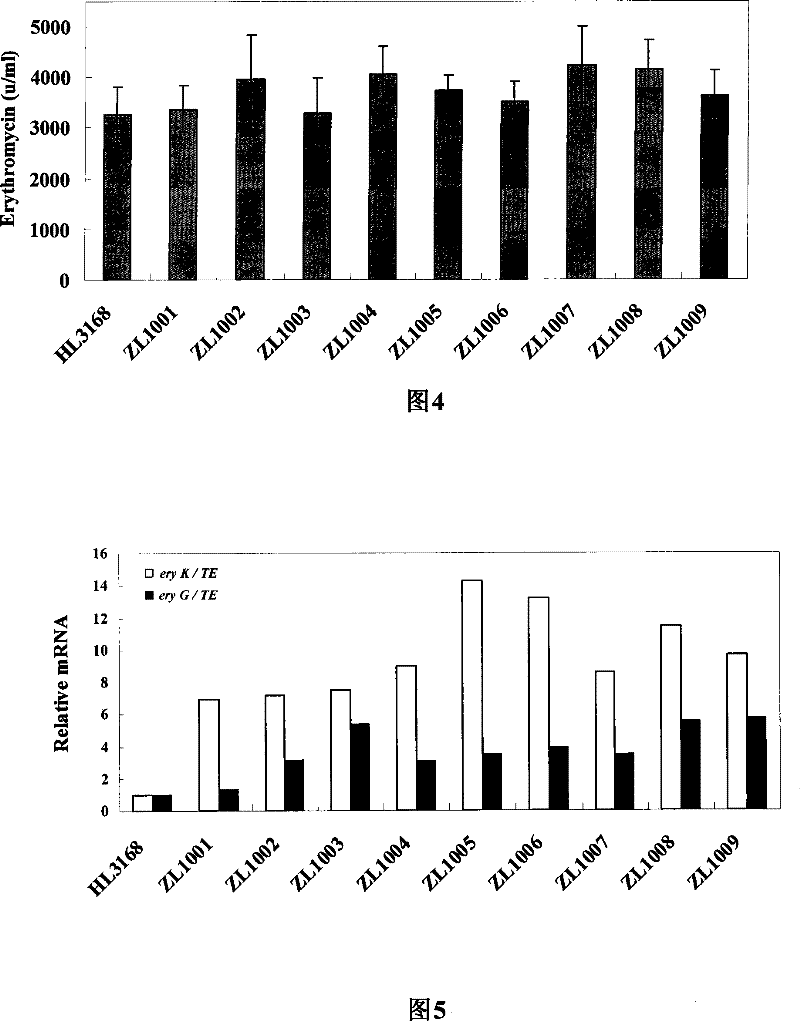

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Establishment of Genetic Transfer System of Erythromycin Industrial Production Bacteria HL3168 E3

[0053] Culture E.coli ET12567 containing appropriate plasmids to OD 600 =0.5-0.6, the bacterial cells in 25mL culture medium were collected by centrifugation, washed twice with an equal volume of LB, resuspended in 2mL LB, and used as E. coli donor cells. Take 500 μL of 20% glycerol spore suspension of S. erythraea HL3168E3 frozen at -80°C, wash twice with an equal volume of TES buffer, resuspend in an equal volume of TES buffer, and heat shock at 50°C for 10 minutes to germinate the spores. Add an equal volume of TSB and incubate at 37°C for 2-5hr. Centrifuge and resuspend in 0.5-1 mL LB as Streptomyces recipient cells. Mix 100 μL of different concentrations of recipient cells with an equal volume of donor cells and directly spread in the solution containing 10 mM MgCl 2 After incubating at 30°C for 20 hrs on MS plates, gently wash the surface of the plates ...

Embodiment 2

[0054] The shaking flask fermentation of embodiment 2 erythromycin

[0055] Erythromycin industrial production strain HL3168 E3 and its recombinant strain in slant medium [ / L: 10g cornstarch, 10ml corn steep liquor, 3g sodium chloride, 3g ammonium sulfate, 5g calcium carbonate, pH7.0, 2g agar powder] (Appropriate antibiotics are added to the culture medium when the recombinant bacteria are cultured) 34 ° C for 7 days to grow spores, which are used as seeds for liquid fermentation.

[0056] For liquid fermentation, take 1 cm from the slant medium 2 Insert 50ml of fermented seed medium into large and small squares [ / L: 50g cornstarch, 18g soybean cake powder, 13ml corn steep liquor, 3g sodium chloride, 1.2g ammonium sulfate, 1.2g ammonium nitrate, 5ml soybean oil, 6g calcium carbonate, pH6. 8~7.0] at 34°C and 250rpm for 2 days. Then transfer 5ml of seed culture solution to 50ml fermentation medium [ / L: 40g cornstarch, 30g soybean meal powder, 30g dextrin, 2g ammonium sulfate, ...

Embodiment 3

[0057] Example 3 Extraction of erythromycin fermentation broth product

[0058] In a 100ml beaker, accurately measure an appropriate amount of fermentation broth and adjust the pH to 8.9 with NaOH. If the sample is frozen, it should be thawed, mixed evenly and quantitatively transferred to a 250ml volumetric flask, made to volume with water, mixed evenly, and centrifuged at 8000-9000 for 10min.

[0059] Take 25ml of the above solution in a 125ml separating funnel, add 25ml of n-hexane, shake for 5min, collect the water phase (lower layer) in a centrifuge tube, wash the hexane layer with water twice, mix the water phase with the water phase of the centrifuge tube, add 10ml Chloroform, shake vigorously for 5 minutes, and centrifuge at 2500 for 5 minutes. Depending on the sample, an emulsion may form on the interface. Use a glass rod to disperse or centrifuge again. Discard the aqueous phase, transfer the chloroform (lower layer) to a 10ml vial, and concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com