Hydrogen phosphate/tricalcium silicate composite self-curing material with biological activity, preparation and uses thereof

A technology of tricalcium silicate and calcium hydrogen phosphate, used in pharmaceutical formulations, dental preparations, compression mold cups, etc., can solve the problem of not meeting the mechanical requirements of dental tissue repair materials, poor bone-like apatite deposition ability, and low bonding strength. and other problems, to achieve the effects of excellent biological properties, excellent biological activity, and slow degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Blending liquid preparation

[0042] Weigh 1.0 g of analytically pure sodium bicarbonate and dissolve it in 99.0 mL of deionized water to obtain a 1.0% sodium bicarbonate solution, sterilize, seal it in a sterile bottle, and set aside.

[0043] 2) Preparation of calcium hydrogen phosphate / tricalcium silicate composite bone defect filling material:

[0044] Fully mix the calcium hydrogen phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 20wt.% and the blending solution at a liquid-solid mass ratio of 0.6:1 for 0.5-1 minute, pour into the mold, and heat at 37°C and 100% humidity conditions for more than 7 days, and then the mold is released to obtain calcium hydrogen phosphate / tricalcium silicate composite material balls for bone defect filling. The compressive strength of the pellet can reach more than 30MPa, and it also has good biological activity.

Embodiment 2

[0046] 1) Blending liquid preparation

[0047] Analytical pure disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) and sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) preparing a sodium phosphate buffer solution with a pH value of 7.0-7.5, the concentration of the solution can be adjusted as required, and the range is 0.1-1.0 mol / L. Sterilize, seal in a sterilized bottle, and keep it for later use.

[0048] 2) Preparation of calcium hydrogen phosphate / tricalcium silicate composite self-curing material:

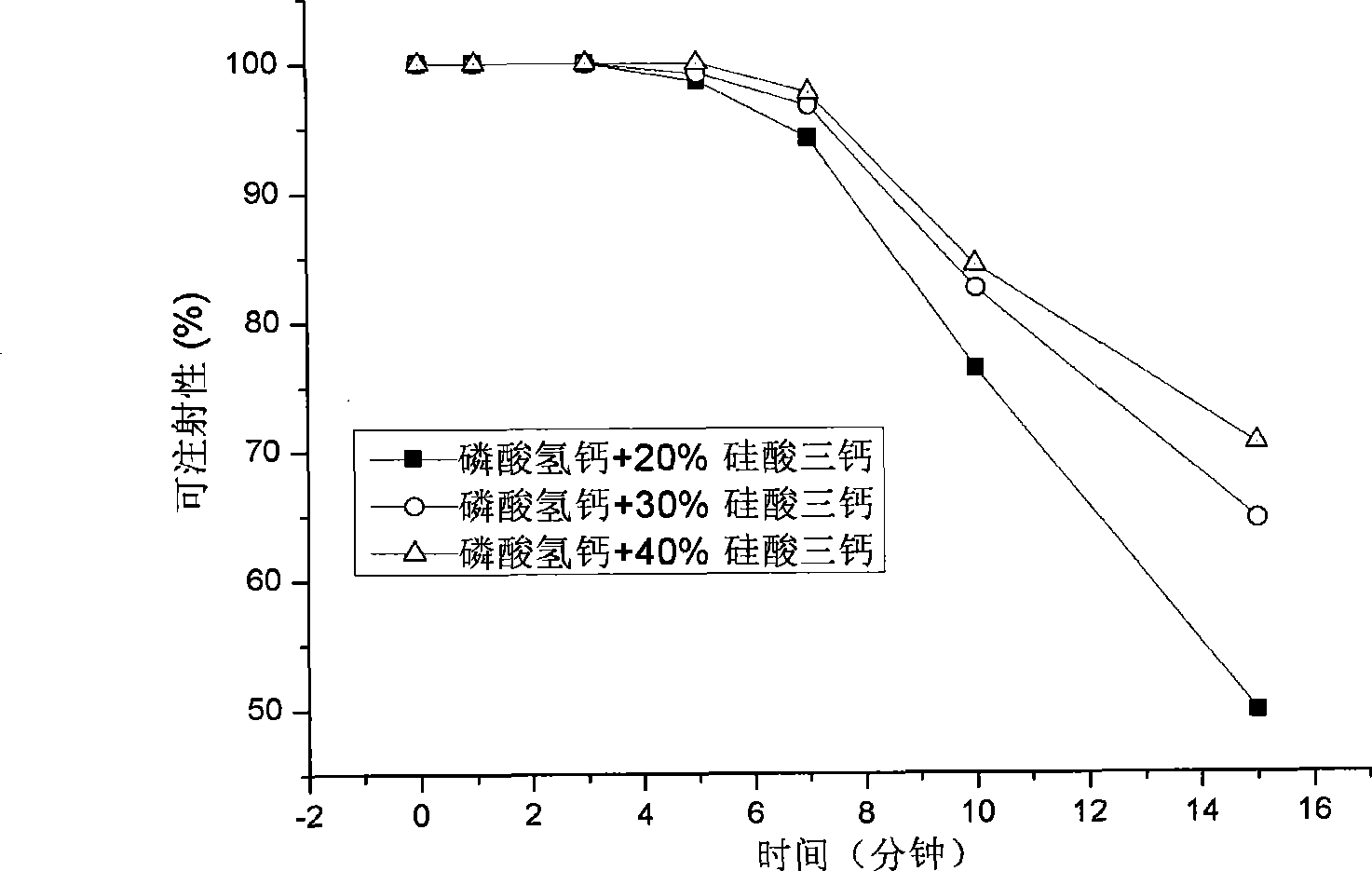

[0049] The calcium hydrogen phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 20wt.% and the blending solution are fully blended at a liquid-solid mass ratio of 0.6:1 for 0.5-1 minute to obtain a minimally invasive Therapeutic calcium hydrogen phosphate / tricalcium silicate composite self-curing material. The self-curing material can reach the initial setting in about 20 minutes after being injected into the defect site, and the ...

Embodiment 3

[0051] 1) Preparation of blending solution

[0052] The simulated body fluid is used as the blending solution, and the ion concentration of the simulated body fluid is shown in Table 2 (pH=7.25-7.4):

[0053] Table 2

[0054] Ion species Na + K + Mg 2+ Ca 2+ Cl - HCO 3 - HPO 4 2- ion concentration

mmol / L) 142.0 5.0 1.5 2.5 148.8 4.2 1.0

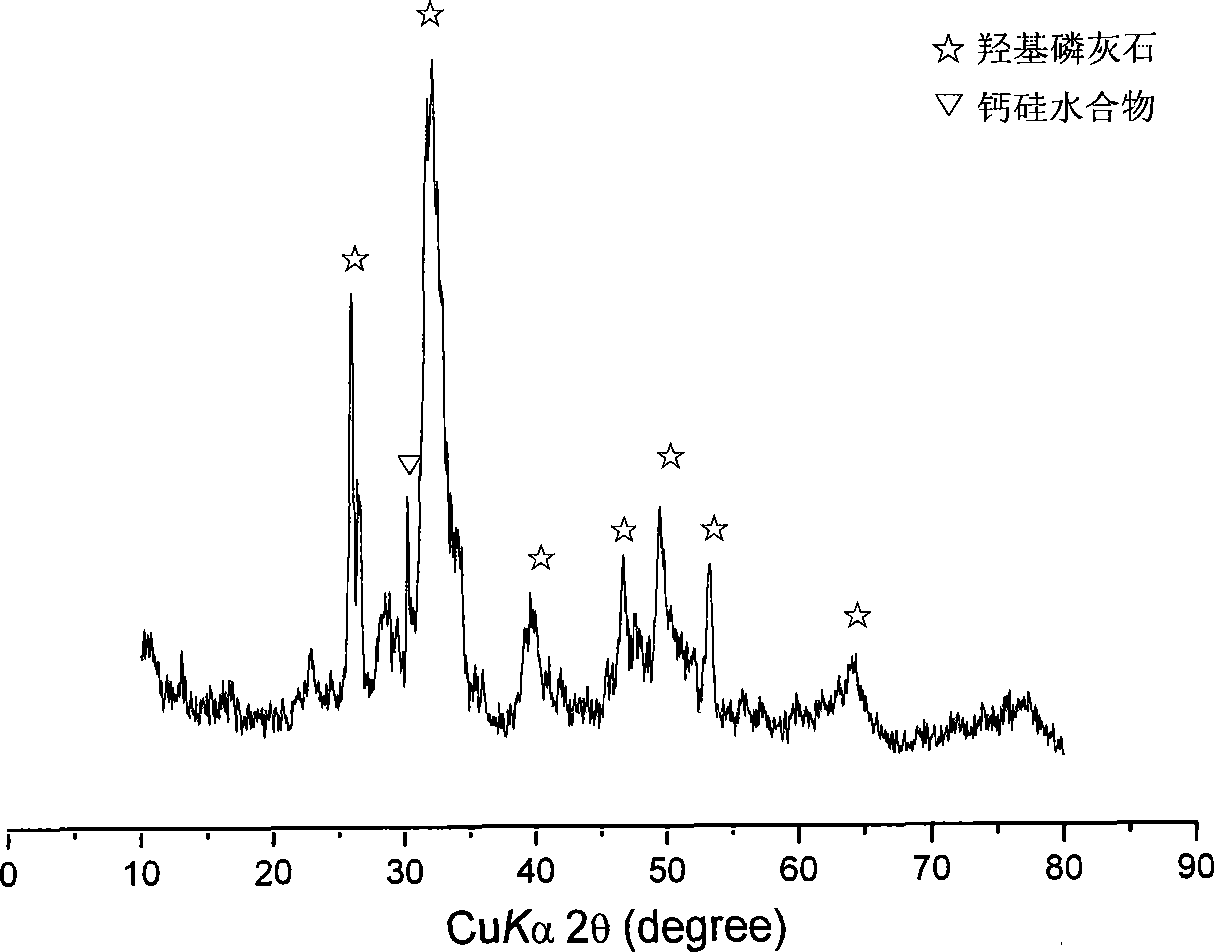

[0055] 2) Preparation of calcium hydrogen phosphate / tricalcium silicate composite degradable material

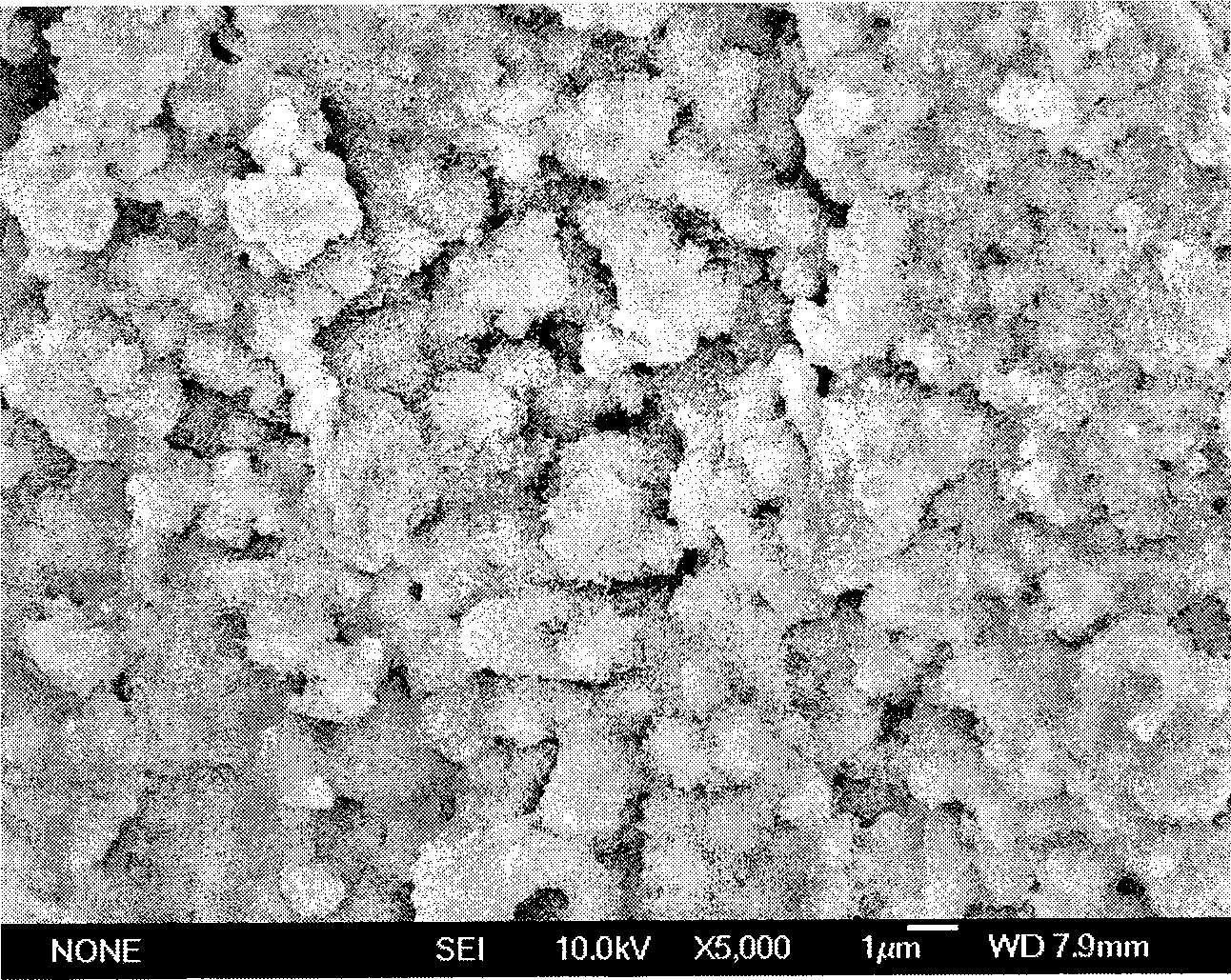

[0056] Fully blend the calcium hydrogen phosphate / tricalcium silicate composite material powder with a tricalcium silicate content of 30wt.% and the blending solution at a ratio of 0.5-1.5:1 to the liquid-solid mass ratio for 0.5-1 minute, inject the mold, and After curing for more than 7 days at 37° C. and 100% humidity, the mold is released to obtain a calcium hydrogen phosphate / tricalcium silicate solidified block material for bone defect filling. The main chemical composition of thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com