Method for preparing high depth-to-width ratio carbon micro electro-mechanical device

A high aspect ratio, electrical device technology, applied in the direction of microlithography exposure equipment, photolithography coating equipment, microstructure technology, etc., can solve high cost, substrate desorption, high aspect ratio MEMS device process complexity and other issues, to achieve the effect of low cost, fine graphics, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation steps: grow a layer of SiO on the surface of a 2-inch silicon wafer by thermal oxidation 2 layer with a thickness of 20nm, thoroughly cleaned with acetone and deionized water, and baked on a hot plate at 200°C for 10 minutes to completely dry;

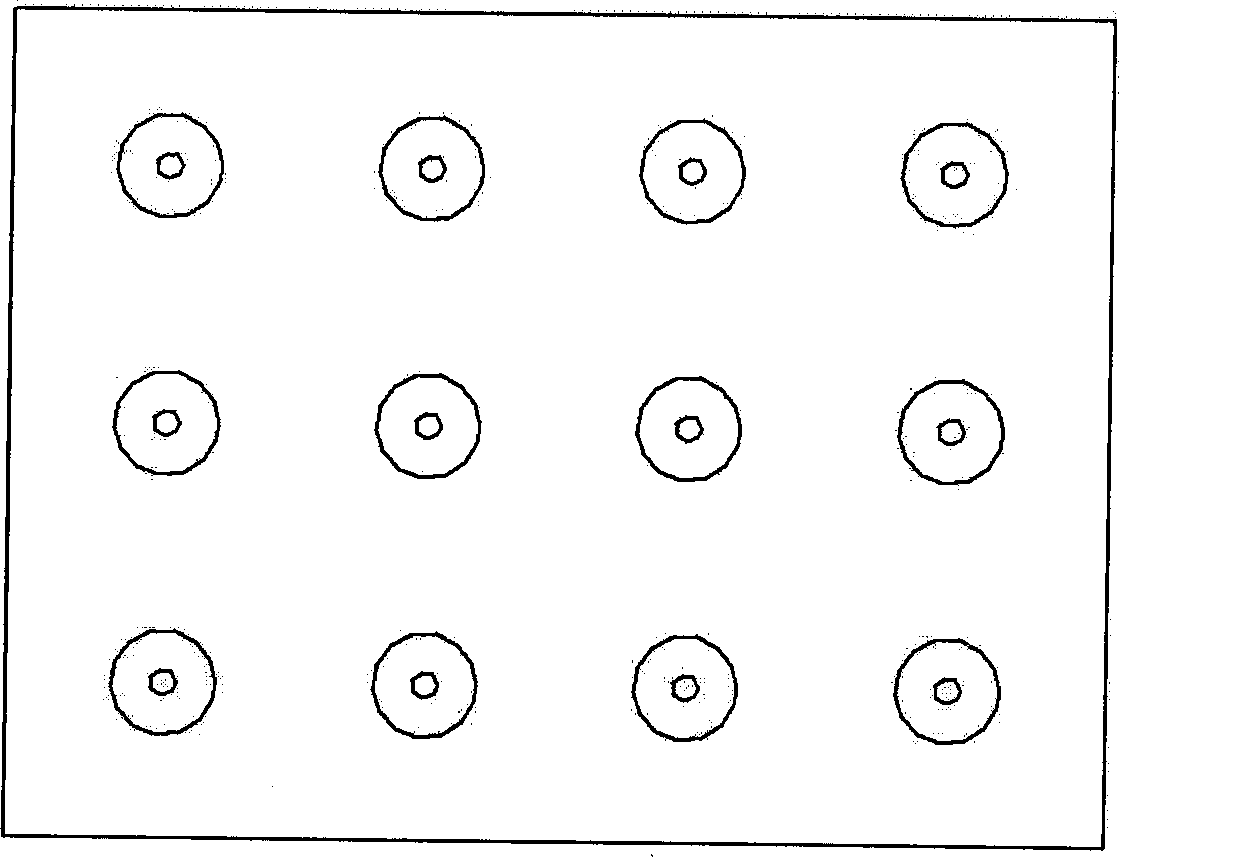

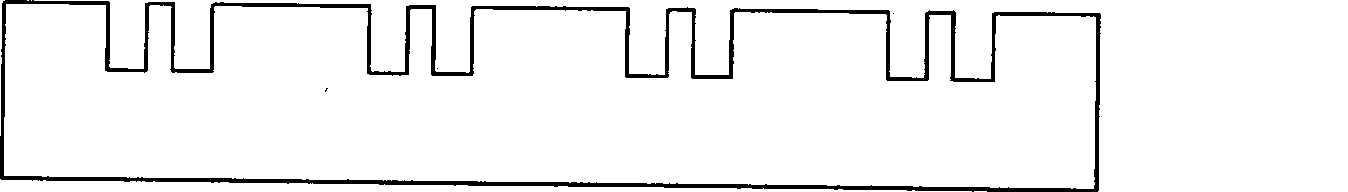

[0035] (2) Substrate etching step: use KW-4A glue homogenizer (Research Department of Microelectronics Center of Chinese Academy of Sciences) 2 A layer of BP218 positive photoresist (Beijing Chemical Reagent Research Institute) was coated on the layer, and photolithography was carried out with a 1# mask (the model of the photolithography machine used was Karl Suss MA6), and then developed on the photoresist The pattern of the micropit array was made on the surface; then, using the remaining photoresist layer as a mask, dilute HF solution (HF:H 2 O=1:7) etch away the exposed SiO 2 , the remaining SiO 2 layer is used as a mask layer for etching the silicon substrate; etching Si uses TMAH (tetramethylammonium hyd...

Embodiment 2

[0056] (1) Preparation steps: grow a layer of SiO on the surface of a 2-inch silicon wafer by thermal oxidation 2 layer with a thickness of 20nm, thoroughly cleaned with acetone and deionized water, and baked on a hot plate at 200°C for 10 minutes to completely dry;

[0057] (2) Substrate etching step: use KW-4A glue homogenizer (Research Department of Microelectronics Center of Chinese Academy of Sciences) 2 A layer of BP218 positive photoresist (Beijing Chemical Reagent Research Institute) was coated on the layer, and photolithography was carried out with a 1# mask (the model of the photolithography machine used was Karl Suss MA6), and then developed on the photoresist The pattern of the micropit array was made on the surface; then, using the remaining photoresist layer as a mask, dilute HF solution (HF:H 2 O=1:7) etch away the exposed SiO 2 , the remaining SiO 2 layer is used as a mask layer for etching the silicon substrate; etching Si uses TMAH (tetramethylammonium hyd...

Embodiment 3

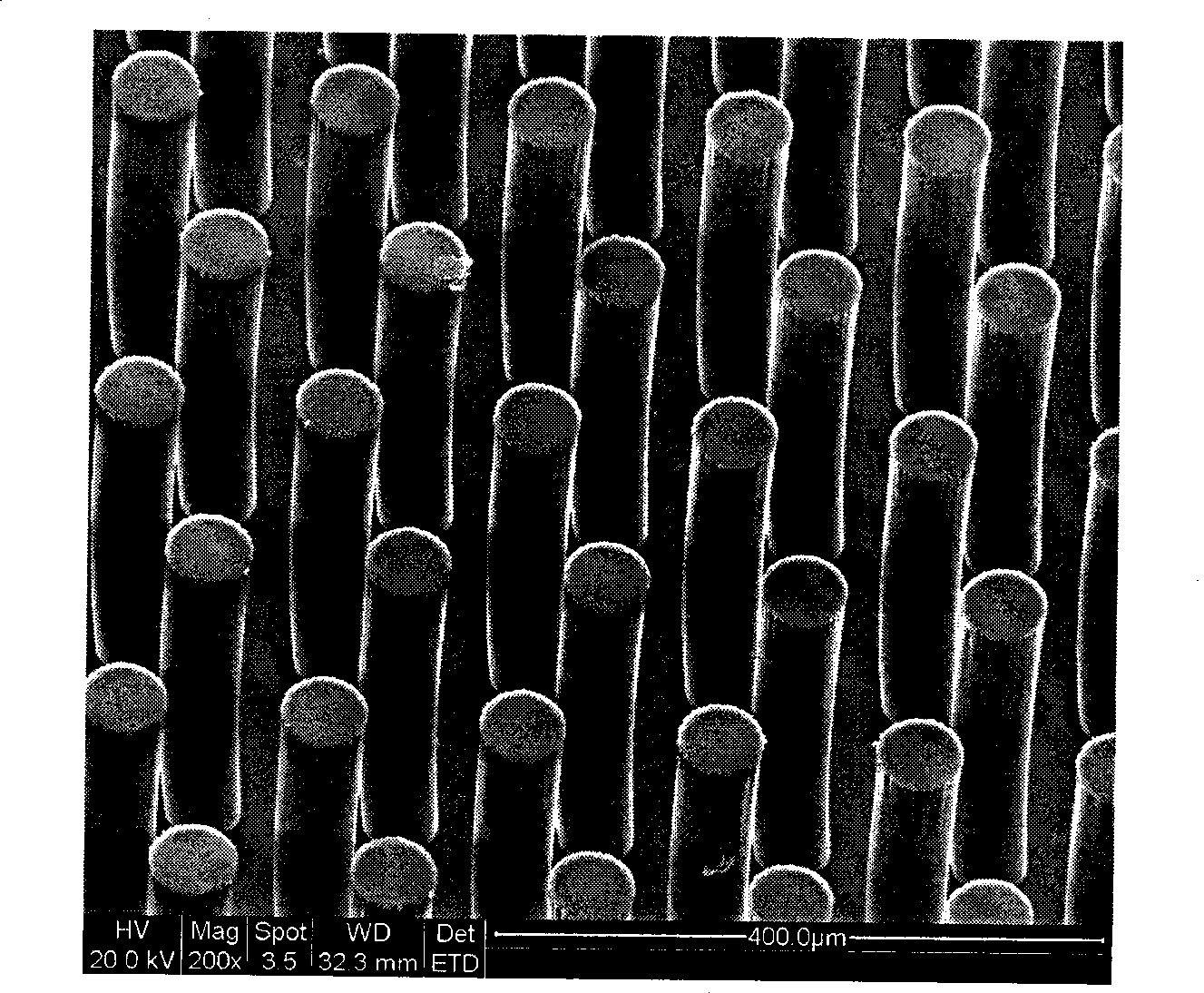

[0068] (1) preparation step, (2) substrate etching step, (3) pretreatment step, (4) glue leveling step, (5) exposure step and (6) development step are completely the same as in Example 1;

[0069] (7) Pyrolysis step: Put the post-baked silicon substrate into a GSL-1400X vacuum tube furnace (Luoyang Weida High Temperature Instrument Co., Ltd.), and gradually increase the temperature for three times for pyrolysis to obtain high aspect ratio carbon. microelectromechanical devices. The specific process is:

[0070] (7-1) Vacuuming, the vacuum degree reaches 10 -3 Tor, the purpose is to release oxygen to prevent the photoresist structure from being burned;

[0071] (7-2) Nitrogen gas is introduced at 2000 milliliters per minute (sccm) under standard conditions, the purpose is to further discharge excess oxygen;

[0072] (7-3) Rise from room temperature to 300°C at a heating rate of 3°C / min, keep warm for 20min, and continue to feed nitrogen at 2000sccm; this process is to furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com