Nickel protoxide / silicon nano-wire and use thereof for preparing integrated super capacitor electrode material

A technology of silicon nanowires and nickelous oxide, applied in the fields of capacitors, electrolytic capacitors, nanostructure manufacturing, etc., can solve the problems of incompatibility of integrated circuits, increased resistance of current collectors, difficult utilization of active materials, etc., and achieves good charging performance. Discharge characteristics, low equivalent internal resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

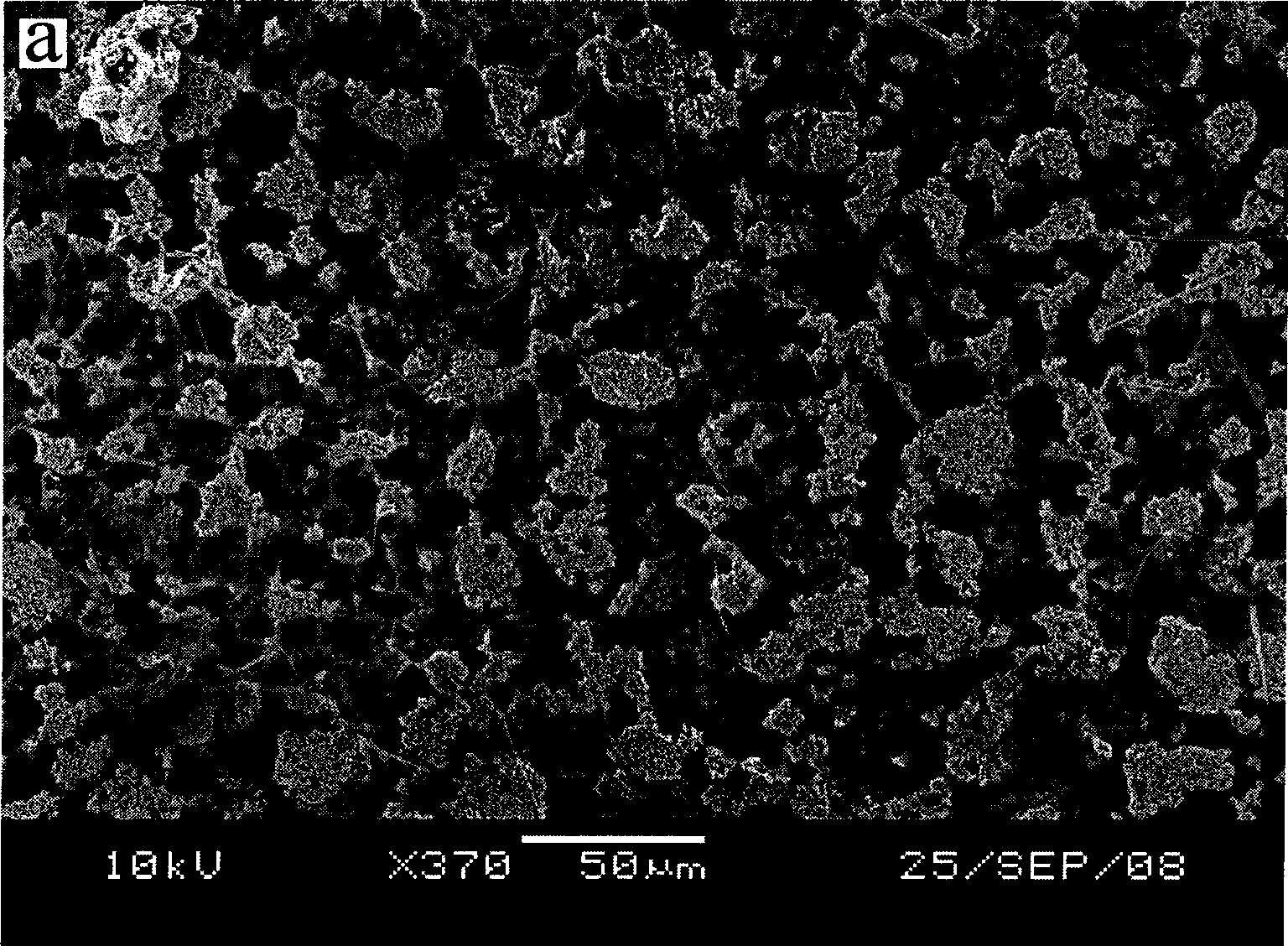

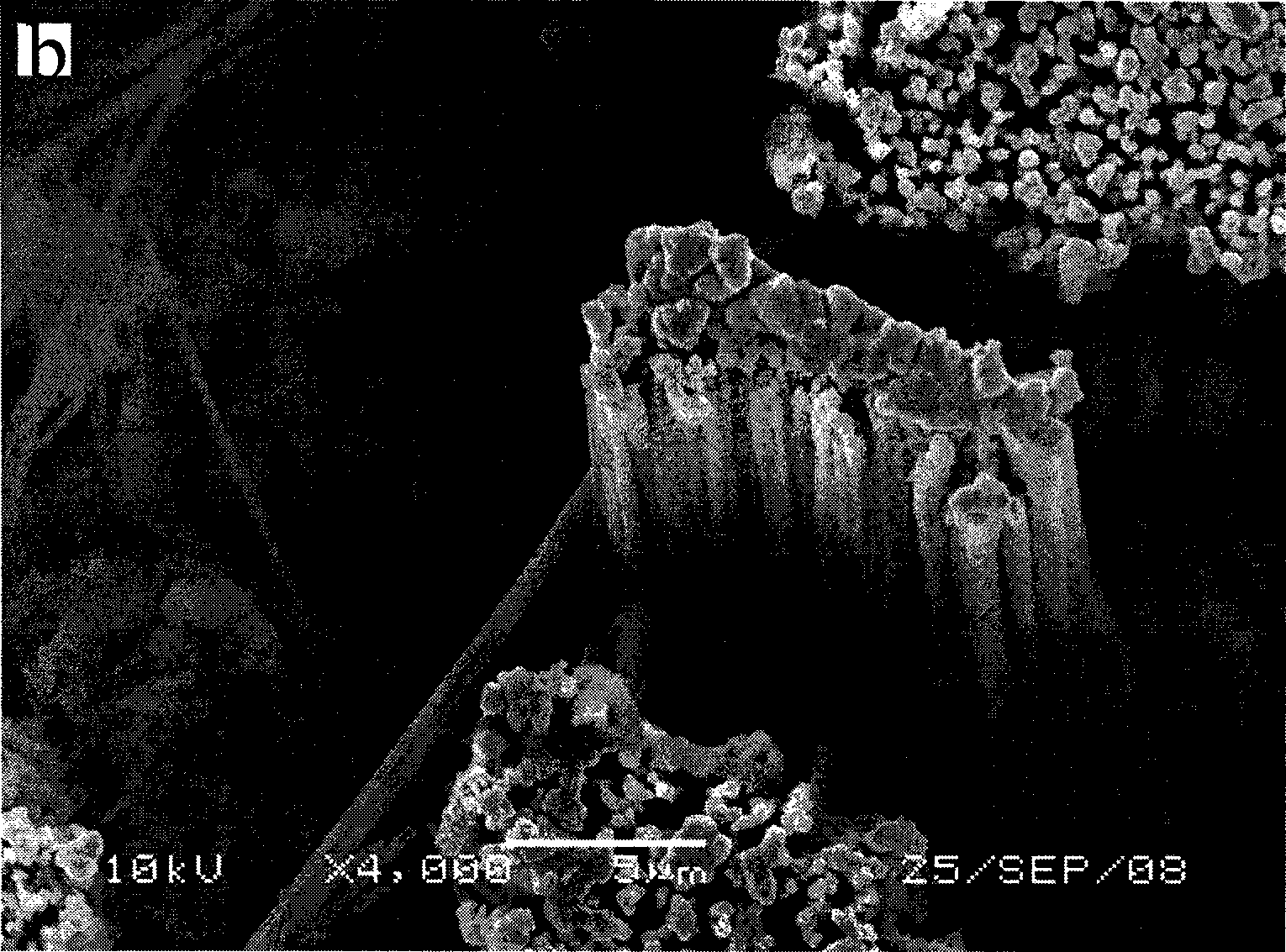

[0029] (1). Fabrication of silicon nanowires (SiNWs) by chemical wet etching

[0030] (a) Choose N-type (100 crystal orientation, resistivity 0.06-0.2Ω·cm) single-sided polished silicon wafer, cut into 1cm x 1cm sample, clean with RCA standard procedure; The surface is pretreated in a hydrofluoric acid solution for 3-5 minutes to activate the surface, and then etched in an etching solution containing 35 mM / L silver nitrate and 20 mass percent hydrofluoric acid for 50 minutes.

[0031] (b) Use a nitric acid solution with a mass concentration of 30% to remove residual silver particles on the surface of the silicon nanowires, then fully wash them with deionized water, and dry them in a drying oven at 70° C. to 80° C. for later use.

[0032] The resulting silicon nanowires had an average diameter of ~80 nm and a length of ~200 μm.

[0033] (2). Electroless deposition of nickel thin layer to make nickel-silicon nanowire composites (Ni-SiNWs)

[0034] The SiNWs prepared above were...

Embodiment 2

[0043] (1). Fabrication of silicon nanowires (SiNWs) by chemical wet etching

[0044] (a) Choose N-type (100 crystal orientation, resistivity 0.06-0.2Ω·cm) single-sided polished silicon wafer, cut into 1cm x 1cm sample, clean with RCA standard procedure; The surface is pretreated in an acid solution for 3-5 minutes to activate the surface, and then etched in an etching solution containing 20 mM / L silver nitrate and 15% by mass hydrofluoric acid for 30 minutes.

[0045] (b) Use concentrated nitric acid solution with a mass concentration of 35% to remove residual silver particles on the surface of the silicon nanowires, then fully wash with deionized water, and dry in a drying oven at 70° C. to 80° C.

[0046] The resulting silicon nanowires had an average diameter of ~200 nm and a length of ~50 μm.

[0047] (2). Electroless deposition of nickel thin layer to make nickel-silicon nanowire composite

[0048] The SiNWs prepared above were pretreated with 1% sodium dodecylbenzenes...

Embodiment 3

[0053] (1). Fabrication of silicon nanowires (SiNWs) by chemical wet etching

[0054] (a) Choose N-type (100 crystal orientation, resistivity 0.06-0.2Ω·cm) single-sided polished silicon wafer, cut into 1cm x 1cm sample, clean with RCA standard procedure; The surface is pretreated in an acid solution for 3-5 minutes to activate the surface, and then etched in a solution containing 25 mM / L silver nitrate and 15% by mass hydrofluoric acid for 30 minutes.

[0055] (b) Use concentrated nitric acid solution with a mass concentration of 30% to remove residual silver particles on the surface of the silicon nanowires, then fully wash with deionized water, and dry in a drying oven at 70°C to 80°C.

[0056] The resulting silicon nanowires had an average diameter of ~150 nm and a length of ~100 μm.

[0057] (2). Electroless deposition of nickel thin layer to make nickel-silicon nanowire composite

[0058] The SiNWs prepared above were pretreated with 1% sodium dodecylbenzene sulfonate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com