Use of rare earth fluoride nano material in MALDI-MS

A technology of rare earth fluorides and nanomaterials, which is applied in the fields of analyzing materials, analyzing materials through electromagnetic means, measuring devices, etc., and achieves the effects of simple preparation methods, high yields, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

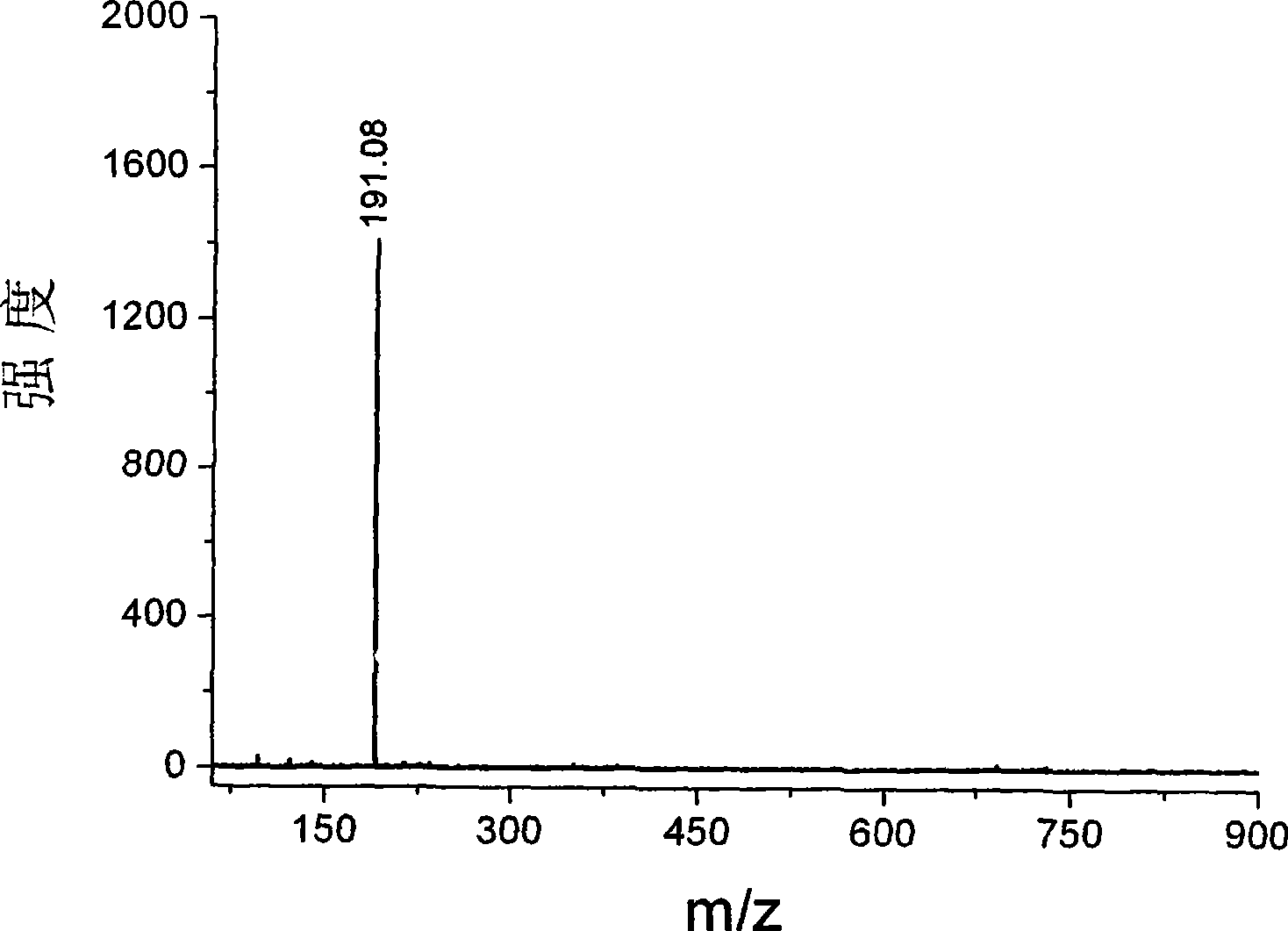

[0038] Example 1. Rare earth fluoride nanomaterials used as MALDI-MS matrix for mass spectrometric analysis of organic acids

[0039] Preparation of Rare Earth Fluoride Nanomaterials

[0040] method 1.

[0041] Weigh 1mmol rare earth metal oxide (Ln 2 o 3, Ln=Y, La, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu) added into 5ml of nitric acid solution with a concentration of 1mol / L; Add amine tetraacetic acid to 5.3-7.8ml of ammonia solution with a concentration of 1mol / L. After it is completely dissolved, mix the two solutions, add 1-2ml of water and 10ml of absolute ethanol, and sonicate in an ultrasonic cleaner for 5 minutes. Weigh 185-259mg of ammonium fluoride and dissolve it in 2ml of water, and add 5ml of absolute ethanol; add the ammonium fluoride solution to the above solution, ultrasonically in an ultrasonic cleaner for 5 minutes to mix the two solutions evenly, and dissolve the solution with nitric acid and ammonia water The pH value of the solution is adjust...

Embodiment 2

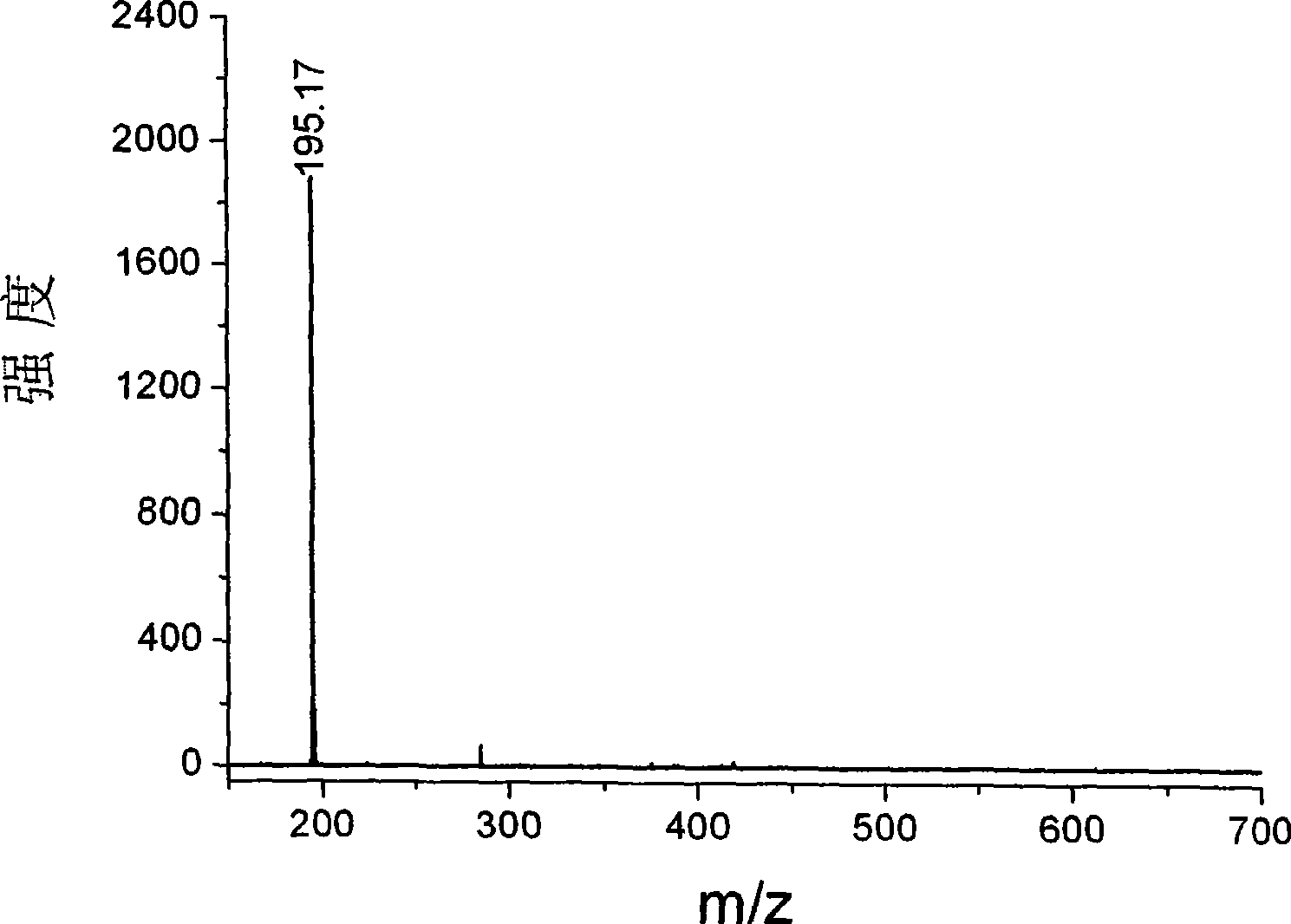

[0052] Example 2. Rare earth fluoride nanomaterials used as MALDI-MS matrix for mass spectrometric analysis of organic bases

[0053] The preparation of rare earth ytterbium fluoride nanomaterial is the same as in Example 1

[0054] The application process of rare earth fluoride nanomaterials as a matrix in MALDI-MS is as follows:

[0055] Step 1. Weigh 1 mg of ytterbium trifluoride hollow nanospheres, add 1 to 2 ml of water, and ultrasonically disperse for 1 to 2 minutes to prepare a matrix solution;

[0056] Step 2. preparation concentration is the 2-phenylbenzimidazole solution of 1mM;

[0057] Step 3. Take 1-2 μL of 2-phenylbenzimidazole solution and spot it on the surface of the metal target, and form a thin layer of the sample after natural drying;

[0058] Step 4. Take 1-2 μL of matrix solution and spot on the thin layer of the sample. After natural drying, mass spectrometry analysis can be performed. The results are shown in figure 2 .

[0059] Yttrium trifluoride...

Embodiment 3

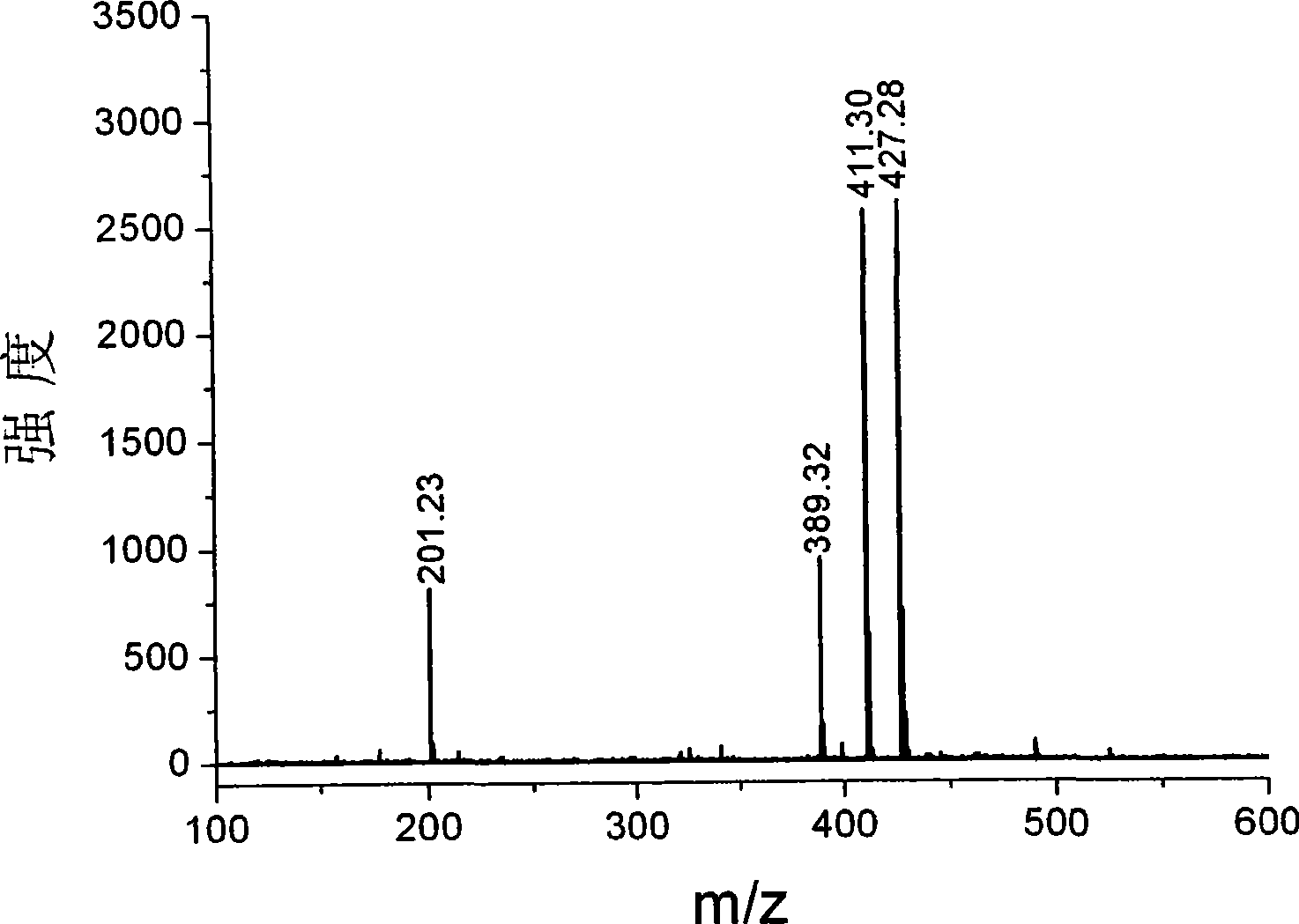

[0060] Example 3. Rare earth fluoride nanomaterials are used as a MALDI-MS matrix for mass spectrometry analysis of diantipyrine methane

[0061] The preparation of rare earth praseodymium fluoride nanomaterial is the same as in Example 1

[0062] The application process of rare earth fluoride nanomaterials as a matrix in MALDI-MS is as follows:

[0063] Step 1. Weigh 1 mg of praseodymium trifluoride nanoparticles, add 1 to 2 ml of methanol, and ultrasonically disperse for 1 to 2 minutes to prepare a matrix solution;

[0064] Step 2. preparation concentration is the diantipyrine methane solution of 1mM;

[0065] Step 3. Take 1-2 μL of diantipyrine methane solution and spot on the surface of the metal target, and form a thin layer of the sample after natural drying;

[0066] Step 4. Take 1-2 μL of matrix solution and spot on the thin layer of the sample. After natural drying, mass spectrometry analysis can be performed. The results are shown in image 3 .

[0067] Yttrium t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com