Method for preparing lithium ferrosilicon silicate of lithium-ion battery cathode material

A technology for lithium ferrous silicate and lithium-ion batteries, which is applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems that the electronic conductivity and tap density are difficult to increase at the same time, and are difficult to meet, and achieve excellent microscopic Structure, structural stability, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention relates to the preparation method of lithium ferrous silicate, the anode material of lithium ion battery, and its steps are as follows:

[0024] 1. Mix lithium salt, ferrous salt, silicon dioxide and additives in proportion (the mixing process can be carried out in conventional mixing equipment, such as inclined mill, cone mixer, three-dimensional mixer for 1 to 24 hours; Wet chemical method can also be used, such as sol-gel method, spray drying method to mix), wherein, the molar ratio of Li: Fe: Si is (1.9-2.1): (0.95-1.05): 1 The addition of additive is the mixture 1-30% of the total mass;

[0025] The above-mentioned additives can be carbon black, graphite or organic compounds that can be decomposed into conductive carbon substances after pyrolysis;

[0026] 2. Put the uniformly mixed raw materials into the heat treatment equipment (any heat treatment equipment that can uniformly heat the reaction mixture under the protection of atmosphere can ...

Embodiment 1

[0032] 2.7g of lithium silicate, 5.4g of ferrous oxalate, and 2g of sucrose were mixed and ball-milled in ethanol for 24 hours. The equipment used was a planetary ball mill with an autopropagation speed of 200r / min. The well-mixed and ground mixed powder was vacuum-dried at 60°C for 24 hours, then pressed into tablets at a pressure of 10 MPa, and raised to 400°C at a rate of 10°C / min under the protection of an argon atmosphere of 1 L / min. Keep it warm for 2 hours, then raise it to 800°C at a rate of 10°C / min, keep it at this temperature for 10h, and then cool it down to room temperature to obtain a lithium ferrous silicate sample.

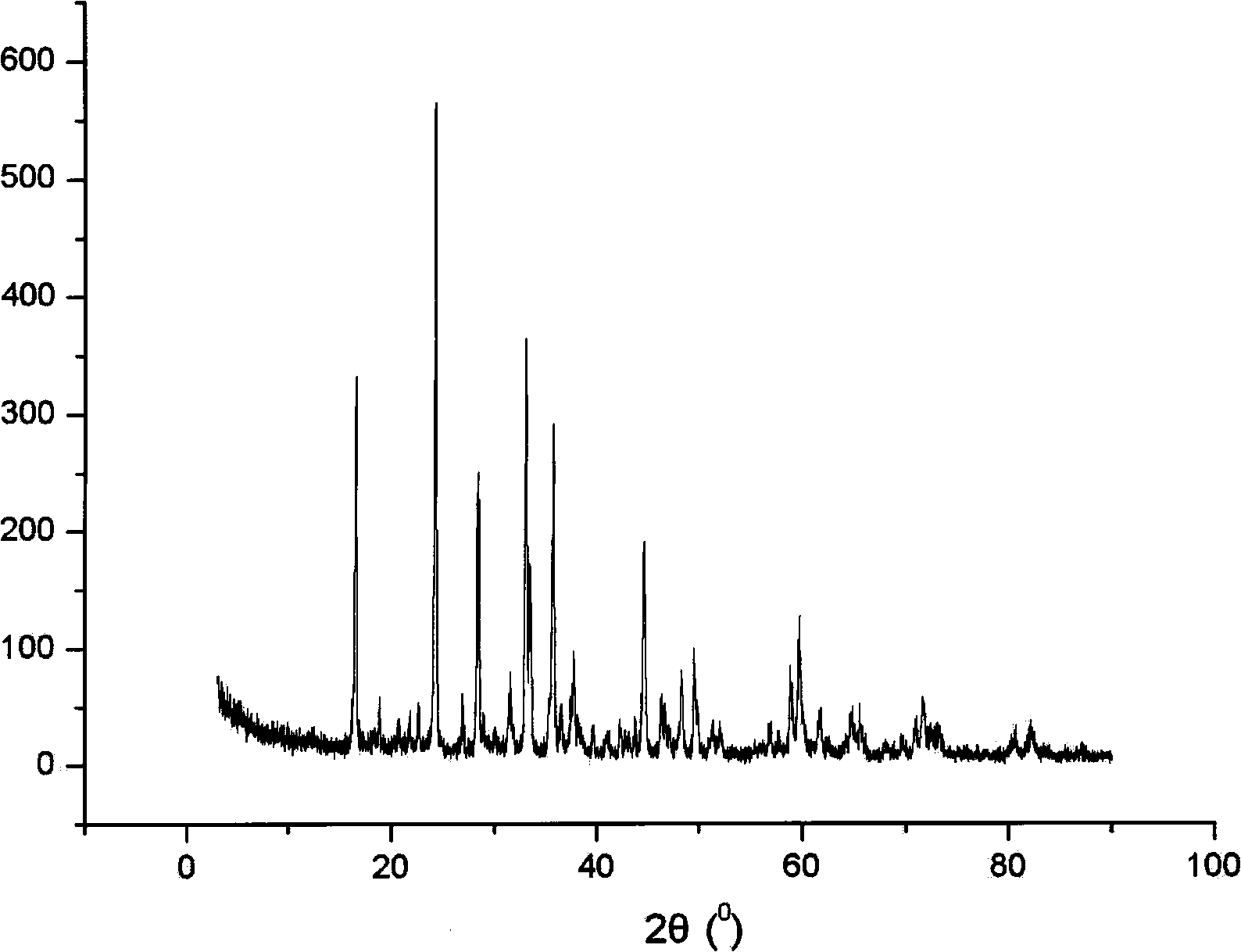

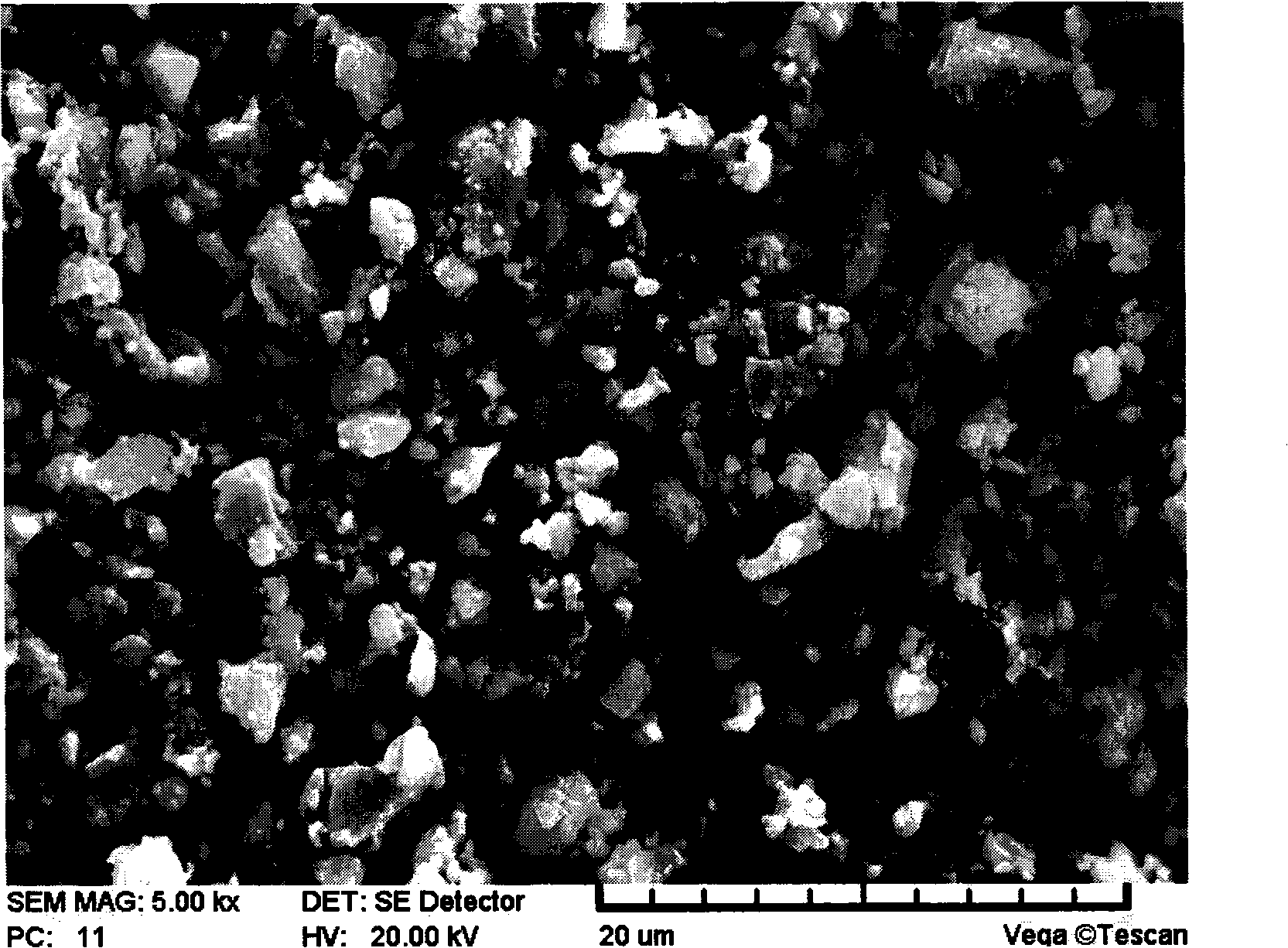

[0033] figure 1 It is the XRD spectrum of the obtained lithium ferrous silicate. Most of the diffraction peaks in the figure can correspond to the characteristic peaks of lithium ferrous silicate, and there are also a small amount of impurities. figure 2 This is the scanning electron microscope photo of the obtained lithium ferrous silicate. The ...

Embodiment 2

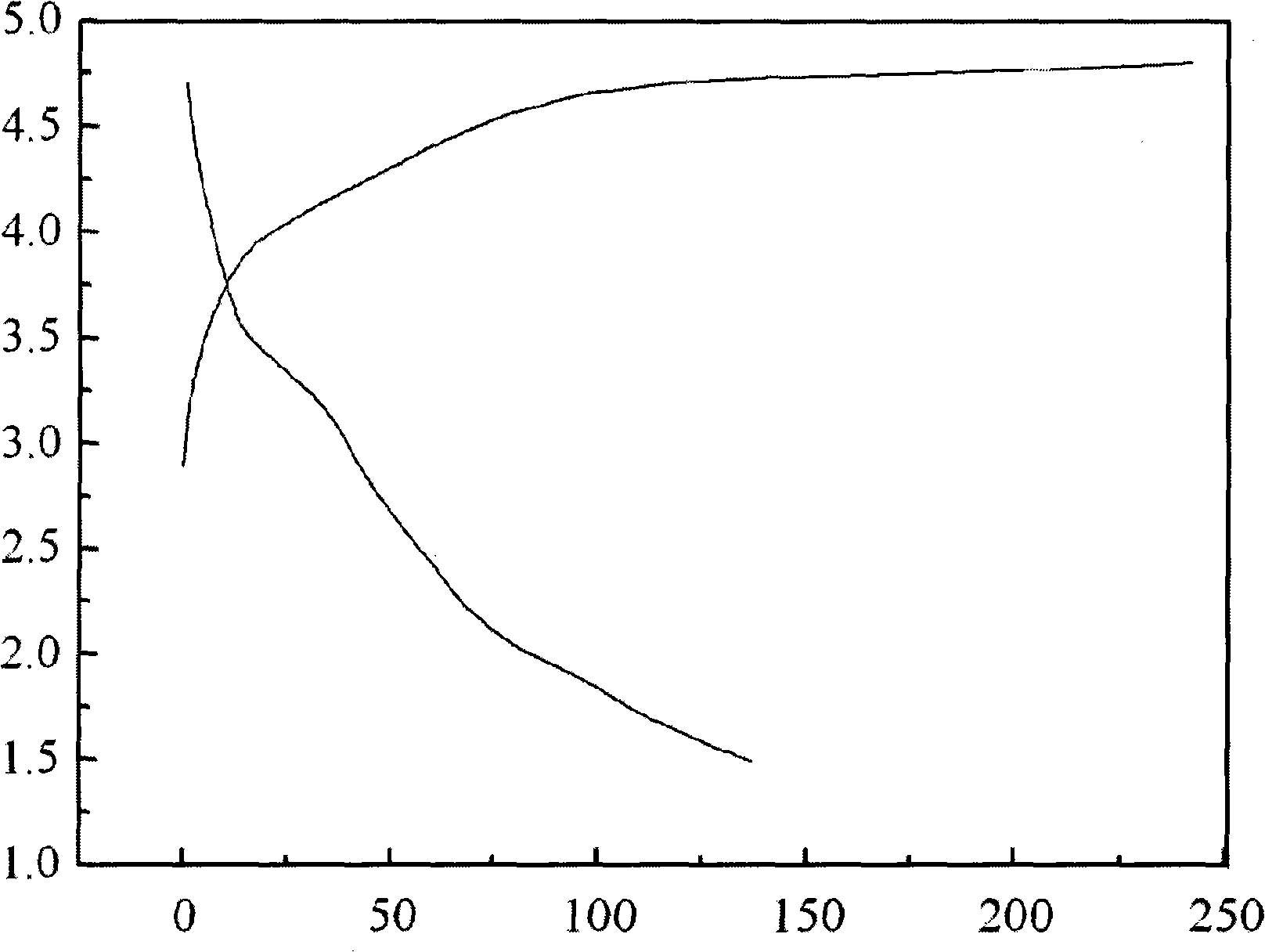

[0036] 2.85g of lithium carbonate, 2.3g of silicon dioxide, 5.4g of ferrous oxalate and 2g of sucrose were mixed and ball milled in ethanol medium for 24 hours. The equipment used was a planetary ball mill with an autopropagation speed of 250r / min. The well-mixed and ground mixed powder was vacuum-dried at 60°C for 24 hours, then pressed into tablets at a pressure of 10MPa, and raised to 400°C at a rate of 10°C / min under the protection of an argon atmosphere of 2L / min. Keep it warm for 2 hours, then raise it to 850°C at a rate of 20°C / min, keep it at this temperature for 15h, and then cool it down to room temperature to obtain a lithium ferrous silicate sample. Test its electrochemical performance according to the method of embodiment 1, as Figure 5 As shown, its first cycle reversible capacity is 142mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com