Preparation method of platy strontium carbonate particles

A technology of strontium carbonate and particles, which is applied in the fields of calcium carbonate/strontium/barium, nanostructure manufacturing, chemical recycling, etc., can solve problems such as difficult stable production, difficult control of total sulfur content, harsh working environment, etc., and achieve carbonization condition control Simple, eliminates hydrogen sulfide pollution, and enhances the effect of reducing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

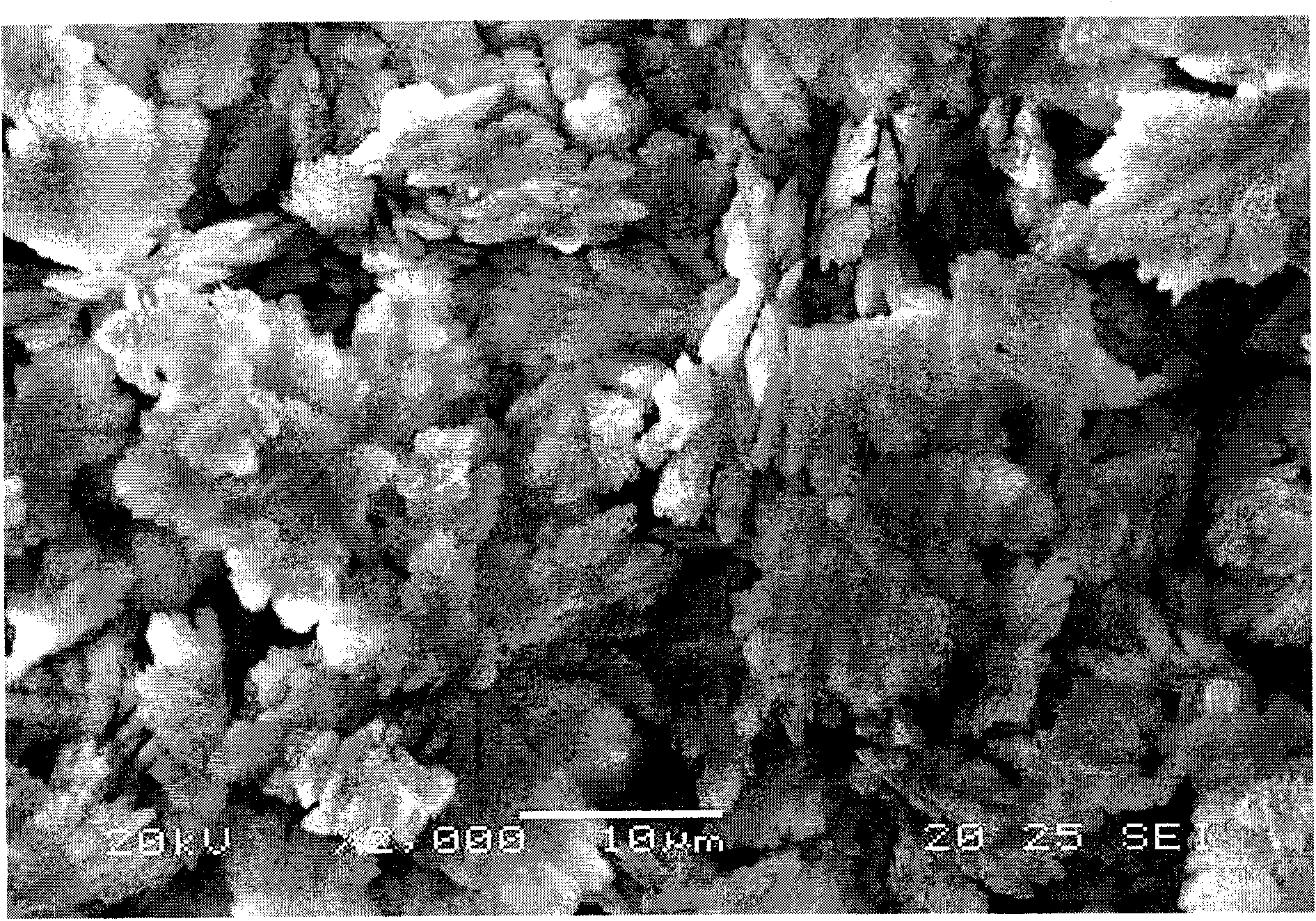

Image

Examples

Embodiment 1

[0025] Embodiment 1, will contain SrSO 4 71.94%, CaCO 3 0.77%, BaCO 3 0.66%, SiO 2 200 grams of 4.22% lapis lazuli ore are broken into particles of 2 to 5 mm, mixed with 80 grams of approximate particle reducing agent powder, while adding water of a total weight of 14 mL, then placed at 1150° C. for 2 hours and roasted for 2 hours to obtain 160 grams of black ash ( Wherein the content of water-soluble strontium is 80%, and the reduction reaction rate is 92%). Put black ash and 1g of gypsum powder ground to 200 mesh into 800ml water for leaching, keep the water temperature at 95±2℃, leaching time is about 2 hours, wash the filter residue with 200ml water after separation, and add the lotion into the leaching filtrate . Under constant stirring and cooling, add triphthalocyanine cobalt sulfonate metal organic compound, make the catalyst concentration in the solution be 35ppm, then add 70ml hydrogen peroxide solution, cool to room temperature, settle, filter and wash to ob...

Embodiment 2

[0027] Embodiment 2, will contain SrSO 4 71.94%, CaCO 3 0.77%, BaCO 3 0.66%, SiO 2 4. 200 grams of 22% lapis lazuli ore is broken into particles of 2 to 5 mm, mixed with 80 grams of reducing agent powder of similar particles, and 5% of the total weight of water is added at the same time, and then placed at 1150 ° C for 2 hours to obtain 160 grams of black ash (wherein the water-soluble strontium content is 80%, and the reduction reaction rate is 92%). Put black ash and 1g of gypsum powder ground to 200 mesh into 800ml water for leaching, keep the water temperature at 95±2℃, leaching time is about 2 hours, wash the filter residue with 200ml water after separation, and add the lotion into the leaching filtrate . Under constant stirring and cooling, add triphthalocyanine cobalt sulfonate metal organic compound, make the catalyst concentration in the solution be 35ppm, then add 70ml hydrogen peroxide solution, cool to room temperature, settle, filter and wash to obtain sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com