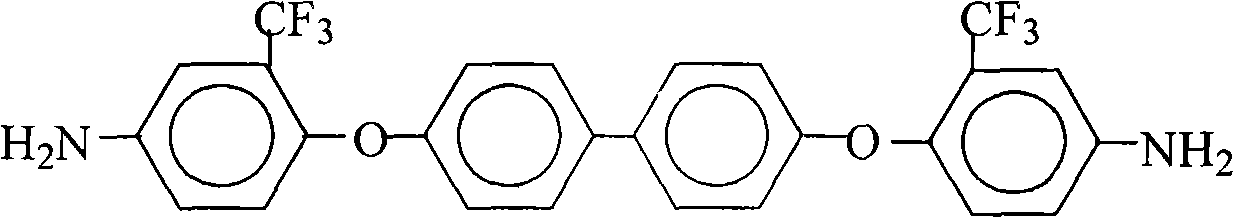

Preparation method of 4,4'-bi(2-trifluoromethyl-4-aminophenoxyl)biphenyl

A technology of aminophenoxy and trifluoromethyl, applied in 4 fields, can solve the problems of high toxicity of hydrazine hydrate, increase of waste water treatment cost, low yield, etc., and achieve the effect of convenient source of raw materials, less types of use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

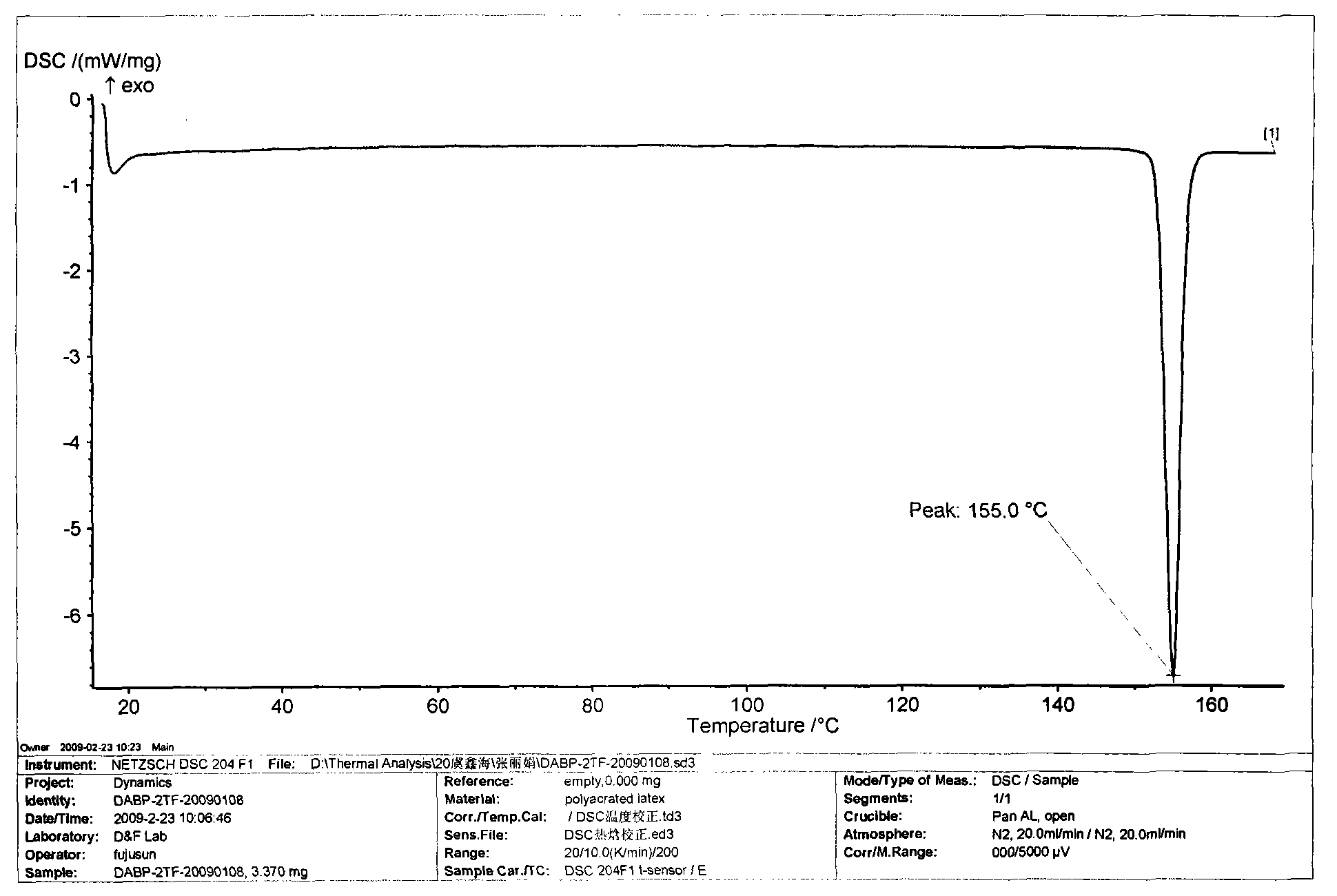

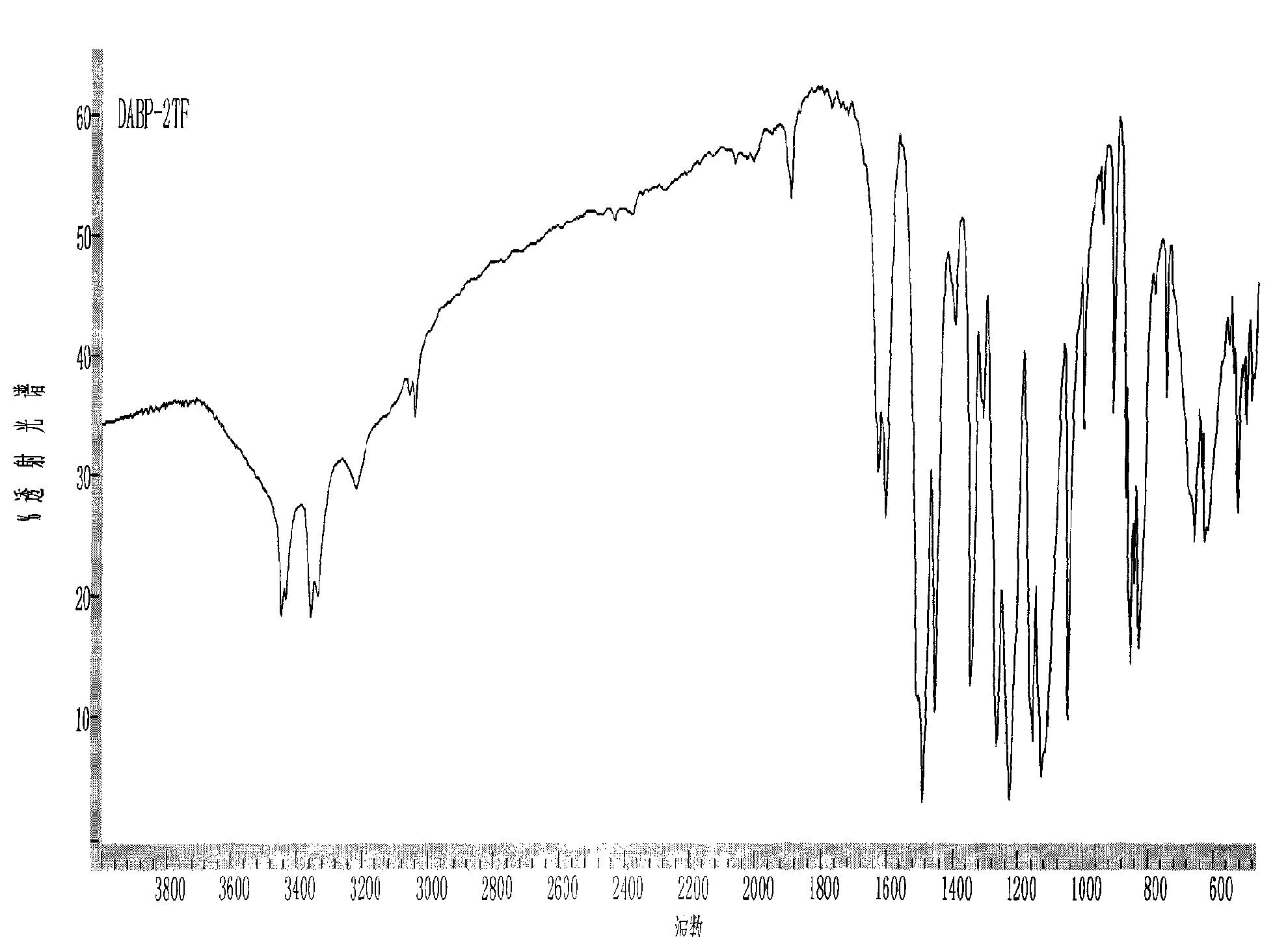

Embodiment 1

[0033] 56.4 grams (0.10 moles) of 4,4'-bis(2-trifluoromethyl-4-nitrophenoxy)biphenyl, 700 milliliters of methanol solvent, 700 milliliters of N-methyl-2-pyrrolidone, 3.2 grams 10% (mass percentage content of metal palladium) palladium / carbon catalyst is added to the high-pressure reactor, hydrogen gas is passed, stirred, the residual air is replaced, hydrogen gas is continued, the temperature is raised to 40 ° C ~ 80 ° C, and the pressure in the reactor is maintained at 0.2 MPa~1.0MPa, keep the reaction for 4 hours, cool the reaction system to room temperature, slowly release the pressure, and pass nitrogen to replace all the residual hydrogen, ensure the inert atmosphere in the high-pressure reactor, filter, recover the filter residue (catalyst), and set aside Mother liquor, concentrate mother liquor, make its solid content control in the scope of 40%-80%, cool and stand, separate out white crystal product, filter, wash with deionized water 2~3 times, 25 ℃ of vacuum drying, ob...

Embodiment 2

[0037] 56.4 grams (0.10 moles) of 4,4'-bis(2-trifluoromethyl-4-nitrophenoxy)biphenyl, 452 milliliters of ethanol solvent, 678 milliliters of N,N-dimethylacetamide, 5.6 Add the palladium / charcoal catalyst of gram 1% (the mass percent of metal palladium) into the autoclave, feed hydrogen, stir, displace the residual air, continue to feed hydrogen, heat up to 40°C to 80°C, and maintain the pressure in the reactor 0.2MPa~1.0MPa, keep the reaction for 4 hours, cool the reaction system to room temperature, slowly release the pressure, and pass nitrogen to replace all the residual hydrogen, ensure the inert atmosphere in the high-pressure reactor, filter, recover the filter residue (catalyst), and leave Take the mother liquor, concentrate the mother liquor so that its solid content is controlled within the range of 40%-80%, cool and stand still, a white crystal product is precipitated, filter, wash with deionized water 2 to 3 times, and dry under vacuum at 25°C to obtain 45.3 g (prod...

Embodiment 3

[0039] 56.4 grams (0.10 moles) of 4,4'-bis(2-trifluoromethyl-4-nitrophenoxy)biphenyl, 1000 milliliters of ethanol solvent, 690 milliliters of ethylene glycol solvent, 0.6 gram of 15% (metal The palladium / carbon catalyst of the mass percentage of palladium) is added to the high-pressure reactor, hydrogen is passed, stirred, the residual air is replaced, the hydrogen is continued, the temperature is raised to 40°C-80°C, and the pressure in the reactor is maintained at 0.2MPa-1.0MPa , keep the reaction for 2 hours, cool the reaction system to room temperature, slowly release the pressure, and pass nitrogen to replace all residual hydrogen, ensure that the autoclave is an inert atmosphere, filter, reclaim the filter residue (catalyst), retain the mother liquor, concentrate the mother liquor , make its solid content control in the scope of 40%-80%, cool and stand still, separate out white crystal product, filter, wash 2~3 times with deionized water, 25 ℃ of vacuum dryings, obtain 46...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com