Crystalline silicon solar battery

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve the problems of low conversion efficiency, lower cell conversion efficiency, increase recombination loss, etc., and achieve the effect of small recombination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

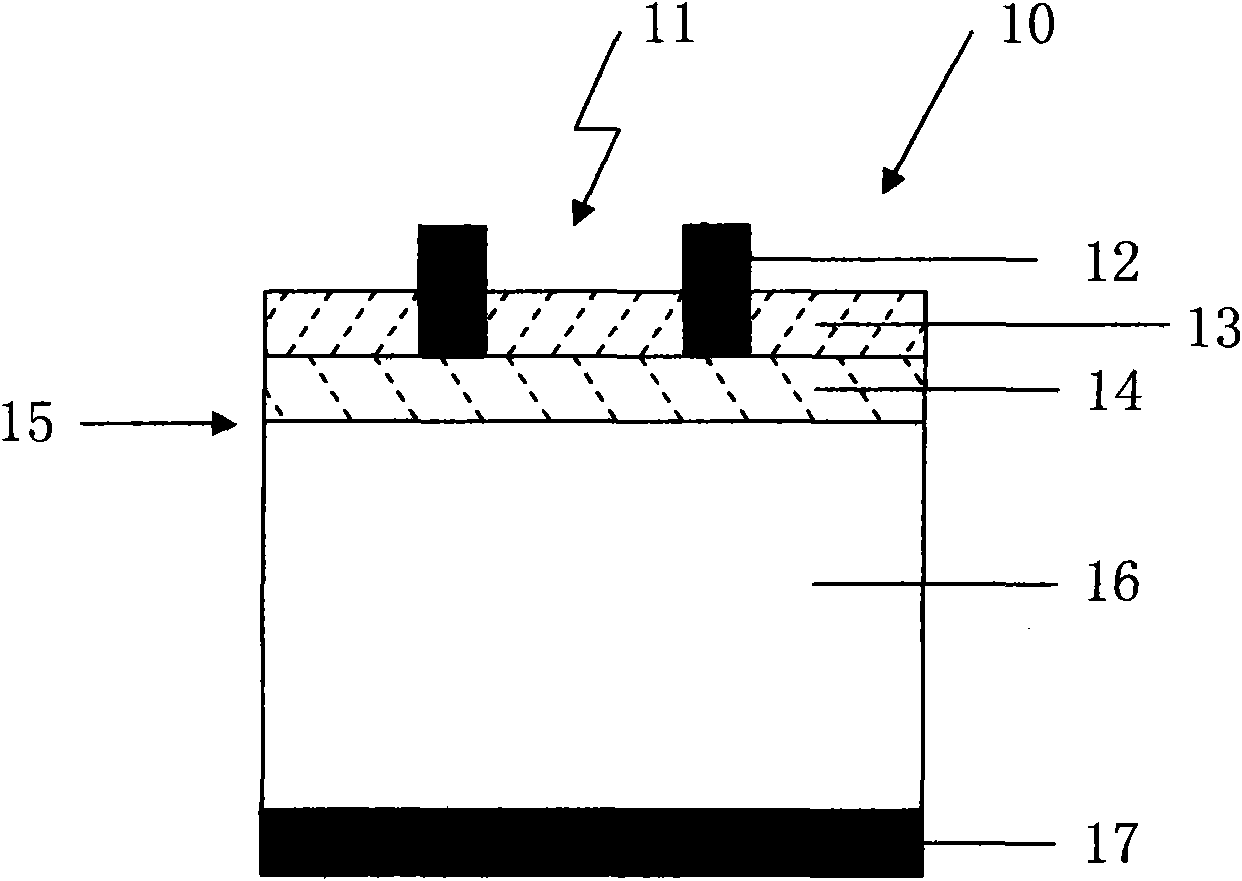

[0049] Follow the steps below to get figure 2 Shown is the p-type crystalline silicon solar cell of the present invention.

[0050] 1. Provide p-type crystalline silicon wafers, whose doping concentration is 4×10 15 ~4×10 16 / cm 3 within range.

[0051] 2. Carry out chemical polishing in a solution containing sodium hydroxide.

[0052] 3. On the back of the p-type crystalline silicon wafer (optional on both surfaces) form a p + Type heavily doped layer, requiring its impurity concentration to be greater than 10 20 / cm 3 , the junction depth is ≥2 μm, and the dopant material can be boron (B).

[0053] 4. The p on the back of the p-type crystalline silicon wafer + A layer of SiO is deposited on the heavily doped layer by atmospheric pressure chemical vapor deposition (APCVD) or low pressure chemical vapor deposition (LPCVD) 2 film, its thickness is required to be greater than 0.5 μm.

[0054] 5. First, use photoresist to coat the p on the back of the p-type crystal s...

Embodiment 1

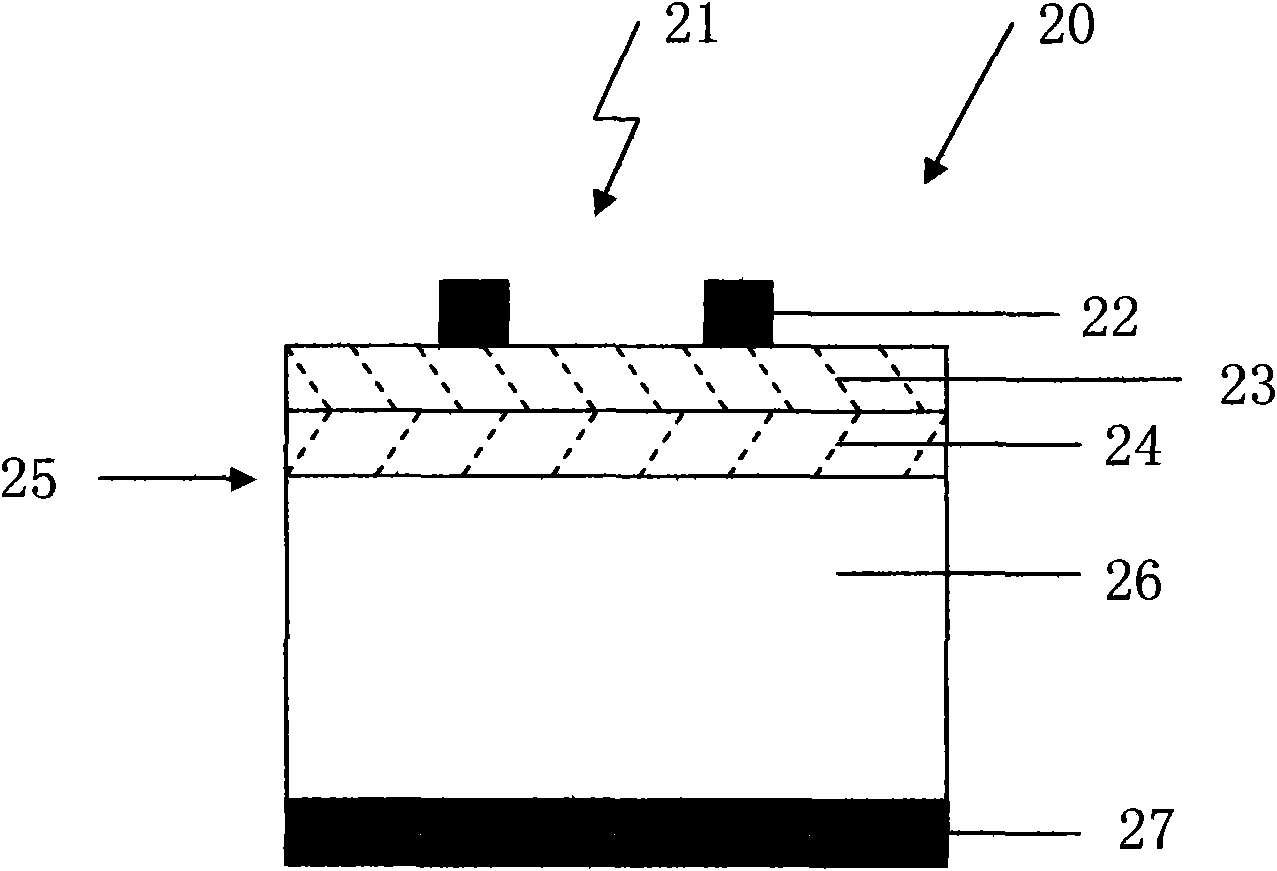

[0063] If the same silicon material as the usual industrial production of crystalline silicon solar cells is used, that is, oriented p-type monocrystalline silicon wafers with a thickness of 0.2mm at the CZ level, the selected process parameters are: resistance of p-type monocrystalline silicon wafers The ratio is about 1Ωcm; the positive n + type doped layer, its thickness is about 100nm, and its doping concentration is about 5×10 19 / cm 3 ; The window layer can be ZnO:Al thin film, its square resistance is about ≤100Ω / □, and its thickness is about 150nm; the distance between the metal grid lines of the front grid-shaped metal electrodes is 2.85mm. Then the conversion efficiency of the battery can reach about 17%, which is about 6% higher than the industrialized average level of common crystalline silicon solar cells.

Embodiment 2

[0065] If the same silicon material as the usual industrial production of crystalline silicon solar cells is used, that is, oriented p-type monocrystalline silicon wafers with a thickness of 0.2mm at the CZ level, the selected process parameters are: resistance of p-type monocrystalline silicon wafers The ratio is about 1Ωcm; the positive n + type doped layer, its thickness is about 10nm, and its doping concentration is about 6×10 18 / cm 3 ; The window layer can be ZnO:Al thin film, its square resistance is about ≤100Ω / □, and its thickness is about 150nm; the distance between the metal grid lines of the front grid-shaped metal electrodes is 2.85mm. Then the conversion efficiency of the cell can reach about 17.8%, which is about 11% higher than the industrialized average level of common crystalline silicon solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com