Method for electrodepositing copper indium diselenide or copper indium gallium selenide film by special pulsing power source

A special pulse, copper indium gallium selenide technology, used in the electrodeposition preparation of solar cell semiconductor materials, electrodeposition copper indium gallium selenide or copper indium gallium selenide thin film field, can solve the problem of surface roughness, deposition current reduction, cathode electrode resistance increase Advanced problems, to achieve the effect of flat and dense surface, tight bonding and high polarization strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

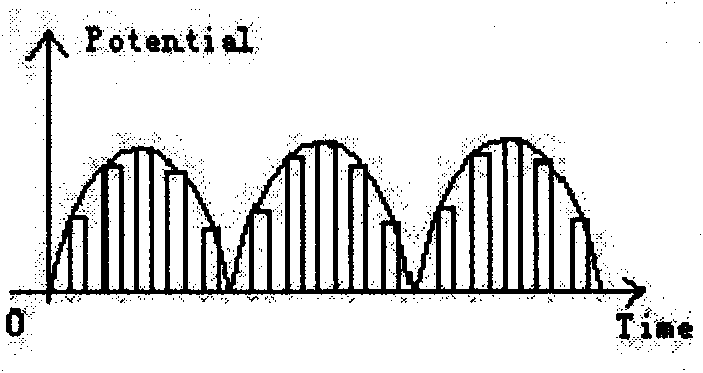

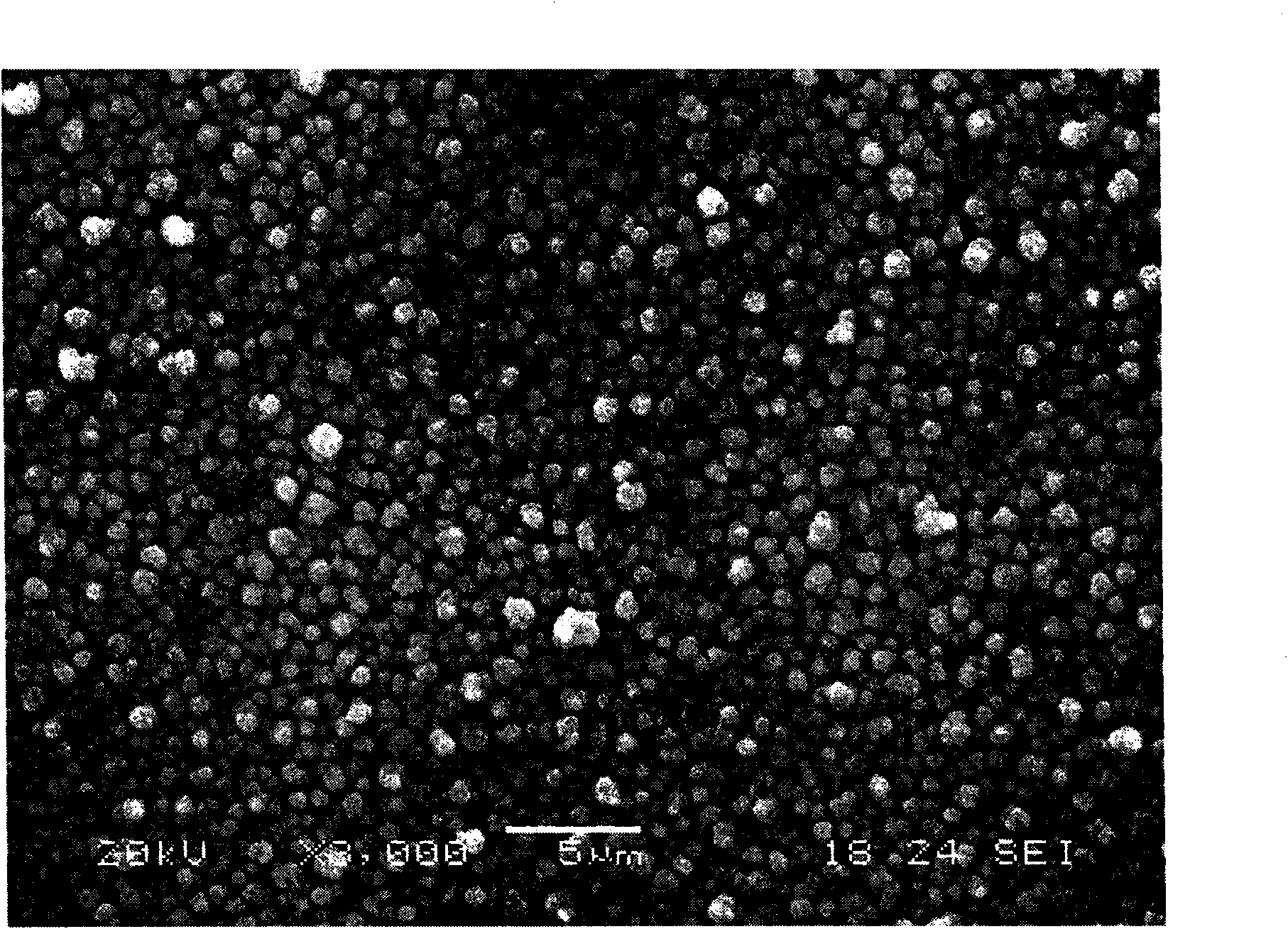

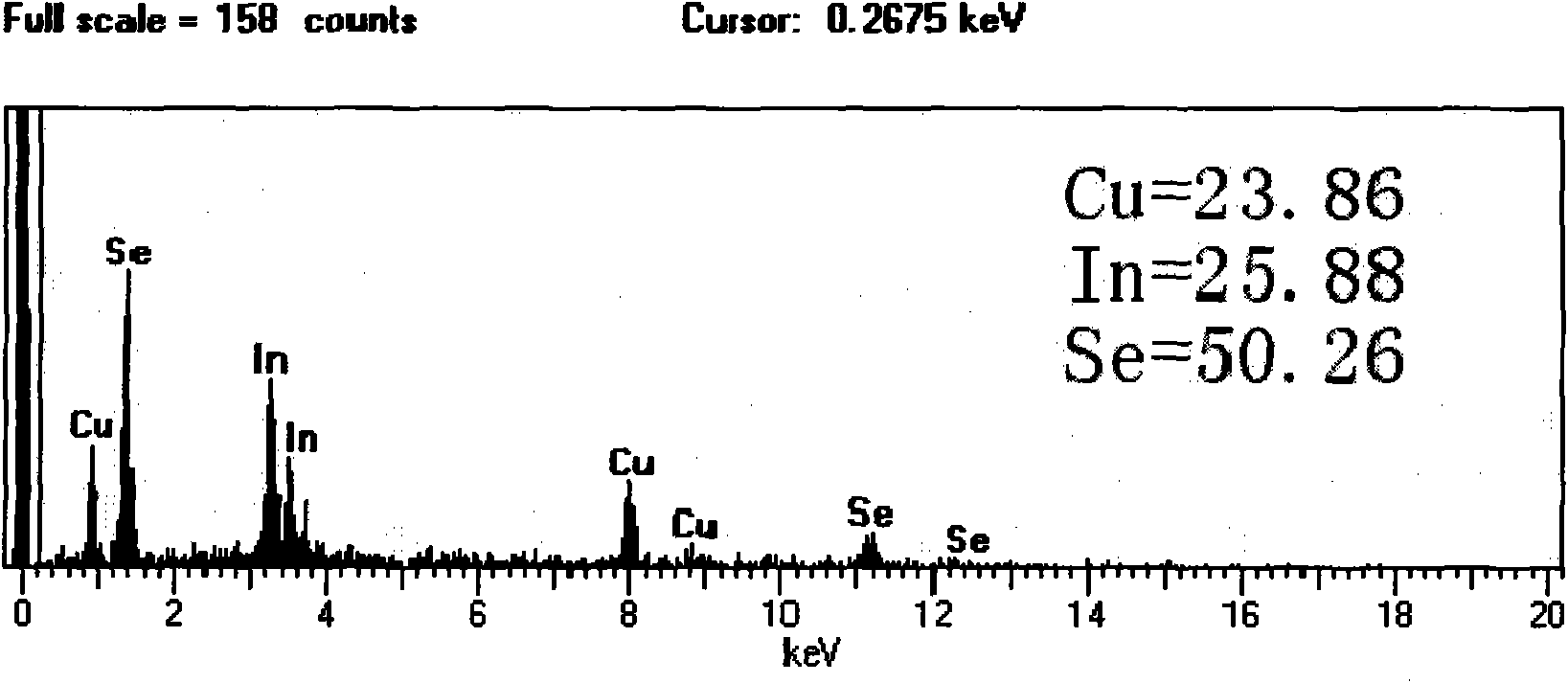

[0029] Electrodeposition adopts a two-electrode electrolysis system, uses Pt mesh as the counter electrode (anode), and ITO conductive glass as the working electrode (cathode), and deposits in the pulse constant current mode. The electrolyte composition is 0.008mol / LCuSO 4 , 0.1mol / L In 2 (SO 4 ) 3 , 0.016mol / L H 2 SeO 3, 0.5mol / L KCl and 0.5mol / L trisodium citrate 20mL deionized aqueous solution (temperature 25 ℃), the solution pH value is adjusted to 1.6 with dilute sulfuric acid (10%, volume); Utilize Chinese patent ZL 200720089930.4 The modulated output of the power supply unit of the published electrochemical water treatment system is as follows: figure 1 The special pulse power supply (square wave modulated by bell wave) used for the electrodeposition of copper indium selenide or copper indium gallium selenide film of the present invention shown, the pulse frequency is 150kHz, the duty ratio is 12.5%, the deposition current is 2mA, and the deposition time 30min, th...

Embodiment 2

[0031] Electrodeposition adopts a two-electrode electrolysis system, uses Pt mesh as the counter electrode (anode), and FTO conductive glass as the working electrode (cathode), and deposits in the pulse constant current mode. The electrolyte composition is 0.005mol / LCuCl 2 , 0.01mol / L InCl 3 , 0.01mol / L SeO 3 50mL deionized aqueous solution (temperature 20 ℃), adjust the pH value of the solution to 1.0 with dilute hydrochloric acid (10%, volume); Utilize the power supply device modulation output of the electrochemical water treatment system announced in the Chinese patent ZL 200720089930.4 as figure 1 The special pulse power supply (square wave modulated by bell wave) used for the electrodeposition of copper indium selenide or copper indium gallium selenide thin film of the present invention shown, the pulse frequency is 26kHz, the duty cycle is 1%, the deposition current is 0.5mA, the deposition The copper indium selenium prefabricated film was prepared in 10 minutes; then ...

Embodiment 3

[0033] Electrodeposition adopts a two-electrode electrolysis system, using Pt mesh as the counter electrode (anode), metal Mo as the working electrode (cathode), and depositing in pulse constant current mode. When the electrolyte composition is 0.01mol / LCu(NO 3 ) 2 , 0.16mol / L In(NO 3 ) 3 , 0.05mol / L SeO 2 , 1mol / L K 2 SO 4 and 50ml deionized aqueous solution (temperature 30 ℃) of 1mol / L trisodium citrate, the solution pH value is adjusted to 2.0 with dilute sulfuric acid (10%, volume); The power supply unit modulates the output as figure 1 The special pulse power supply (square wave modulated by bell wave) used for the electrodeposition of copper indium selenide or copper indium gallium selenide film of the present invention shown, the pulse frequency is 400kHz, the duty cycle is 100%, the deposition current is 3mA, and the deposition time 120min makes the copper indium selenium prefabricated film; Then the copper indium selenium prefabricated film is placed in the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com