Taste-masking coated composition, coated liquid and formulation

A composition and coating technology, which is applied in the directions of non-active ingredients medical preparations, organic active ingredients, antibacterial drugs, etc. Applicable to problems such as suspensions, to achieve the effect of changing bioavailability, good taste masking effect, and stable preparation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

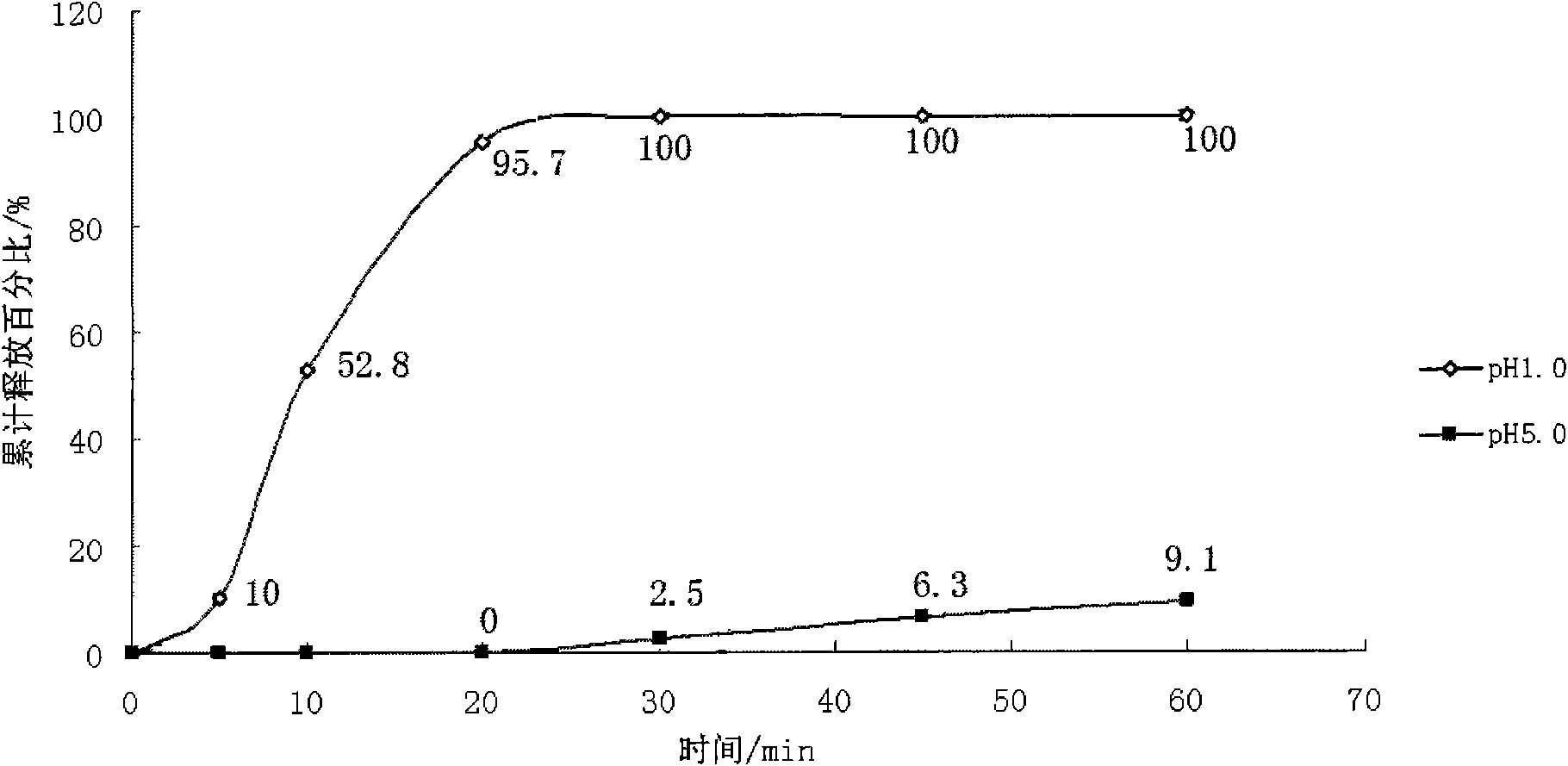

Embodiment 1

[0053] Preparation of doxycycline hydrochloride microcapsule coating preparation:

[0054] Prepare doxycycline hydrochloride microcapsule coating preparation according to the following steps:

[0055] Step 1, preparing coated particles. Weigh each component material according to the following formula:

[0056] Prescription of Coated Granules

[0057] Blank ball core 600g

[0058] Doxycycline Hydrochloride 600g

[0059] Polyvinylpyrrolidone 150g

[0060] Hydroxypropyl Methyl Cellulose 70g

[0061] water 1500g

[0062]

[0063] Total 2920g

[0064] Doxycycline hydrochloride, polyvinylpyrrolidone, and hydroxypropyl methylcellulose are dissolved in water to prepare a drug solution, and blank ball cores with a particle size of 150-200um are put into a fluidized bed for drug application to obtain a drug solution. Coating particles.

[0065] Step 2, preparing a coating solution. Weigh each component material according to the f...

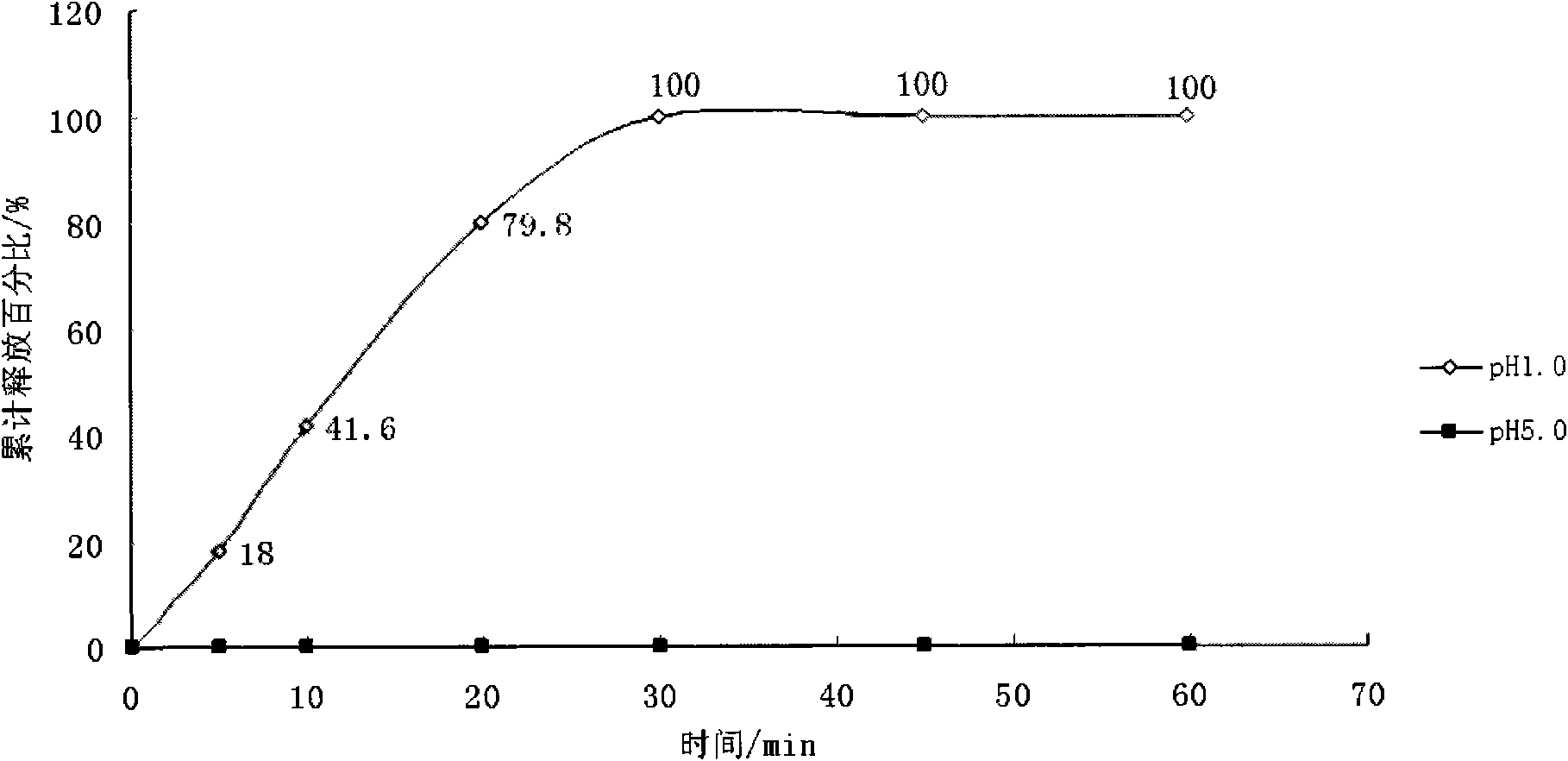

Embodiment 2

[0086] Preparation of Azithromycin Powder Coating Formulation 2:

[0087] Prepare each component material according to the following formula:

[0088] Azithromycin Powder Coating Formulation

[0089] Azithromycin 450g

[0090] Polyvinylpyrrolidone 50g

[0091] Methacrylic resin 375g

[0092] Aminomethacrylic resin 3375g

[0093] Polyethylene glycol 6000 112.5g

[0094] Glyceryl monostearate 125g

[0095] Tween 80 50g

[0096] Water 3462g

[0097] Prepare the azithromycin powder coating preparation as follows:

[0098] Step 1, methacrylic resin in this prescription: aminomethacrylic resin is 1: 9, wherein two kinds of resins are commercially available coating liquid products, solid content is 30%, two kinds of coating liquids are mixed, add 2100g Water, then add polyethylene glycol 6000 plasticization;

[0099] Step 2, add the prescription amount of glyceryl monostearate and Tween 80 into the remaining 1362g of water and mix evenly; then pour into the mixed solution o...

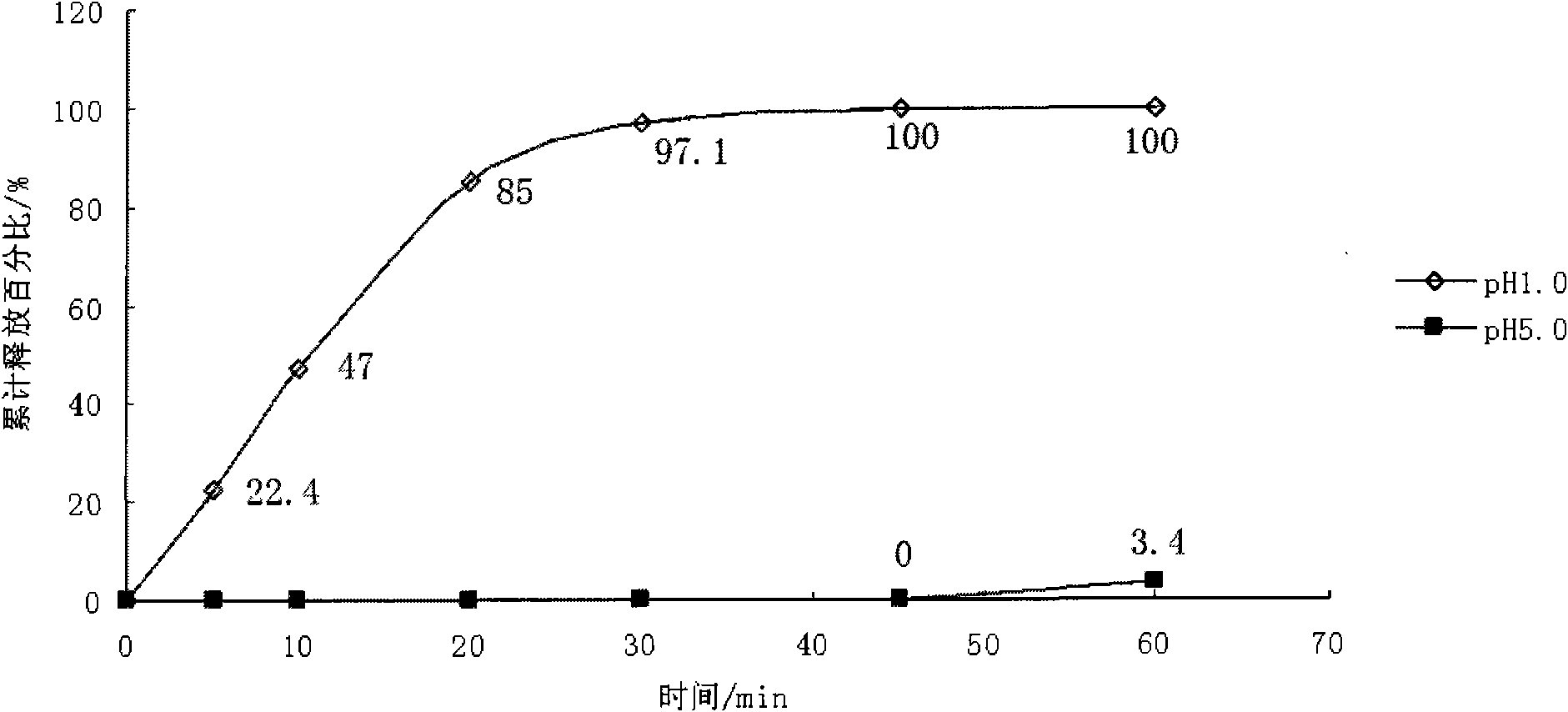

Embodiment 3

[0111] Preparation of Azithromycin Microcapsule Coating Formulation 3:

[0112] Prepare the azithromycin microcapsule coating formulation as follows:

[0113] Step 1, preparing coated particles. Weigh each component material according to the following formula:

[0114] Prescription of Coated Granules

[0115] Microcrystalline Cellulose 335g

[0116] Azithromycin 150g

[0117] Polyvinylpyrrolidone 15g

[0118] water 300g

[0119]

[0120] Total 800g

[0121] Put the prescribed amount of microcrystalline cellulose into a centrifugal granulation pot, mix evenly with azithromycin and polyvinylpyrrolidone, supply the powder, spray into the prescribed amount of water, and centrifugally granulate to obtain core particles.

[0122] Step 2, preparing a coating solution. Weigh each component material according to the formula of the following coating solution:

[0123] Coating Solution Prescription

[0124] Methacrylic resin 391.5g

[0125] Ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com