A method for preparing l-aspartic acid

A technology of aspartic acid and aspartic acid, which is applied in the field of bioengineering, can solve the problems affecting the sustainable production of L-aspartic acid and the high production cost, and achieves the benefits of sustainable production and saving Production cost, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

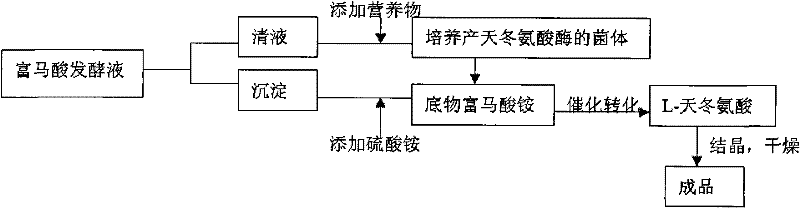

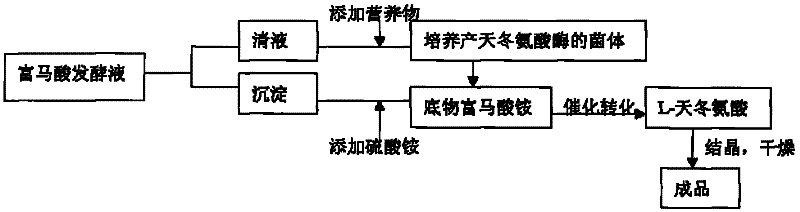

Method used

Image

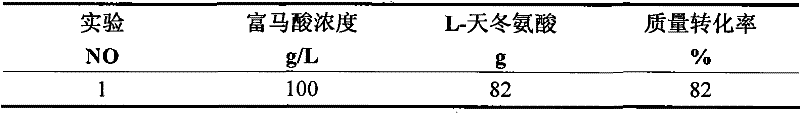

Examples

Embodiment 1

[0028] Fumaric acid fermentation broth:

[0029] Rhizopus oryzae (Rhizopus oryzae ME-F12) strain was used, and the fermentation medium formula was: glucose 130g / L, urea 0.06g / L, KH 2 PO 4 0.6g / L, MgSO 4 ·7H 2 O 0.5g / L, ZnSO 4 ·7H 2 O 0.0176g / L, FeSO 4 ·7H 2 O 0.000498g / L, CaCO 3 It is 60% of the glucose concentration and the pH is 5.5. For fermentation conditions, see literature (Chinese Journal of Biotechnology, 2008, 28(4): 59-64). After the fermentation ended, the concentration of fumaric acid (calcium salt) in the fermentation broth was 66.5g / L, the concentration of residual glucose was 7.8g / L, and the concentration of fumaric acid in the clear liquid was 4.6g / L.

[0030]Bacteria: Escherichia coli (E.coli ATCC 11303)

[0031] (1) Preparation of enzyme-producing medium for producing aspartase microorganisms

[0032] Add nutrients to the supernatant of fumaric acid fermentation broth: beef extract 2g / L, peptone 6g / L, magnesium sulfate 0.25g / L, potassium dihydroge...

Embodiment 2

[0043] The present embodiment is the same as the method of embodiment 1, but the conditions are changed.

[0044] Fumaric acid fermentation broth:

[0045] Rhizopus oryzae (Rhizopus oryzae ME-F12) strain was used, and the fermentation medium formula was: glucose 130g / L, urea 0.06g / L, KH 2 PO 4 0.6g / L, MgSO 4 ·7H 2 O 0.5g / L, ZnSO 4 ·7H 2 O 0.0176g / L, FeSO 4 ·7H 2 O 0.000498g / L, CaCO 3 It is 60% of the glucose concentration and the pH is 5.5. For fermentation conditions, see literature (Chinese Journal of Biotechnology, 2008, 28(4): 59-64). After the fermentation, the concentration of fumaric acid (calcium salt) in the fermentation broth was 62g / L, the concentration of residual glucose was 10.3g / L, and the concentration of fumaric acid in the clear liquid was 4.2g / L.

[0046] Bacteria: Escherichia coli (E.coli ATCC 11303)

[0047] (1) Preparation of enzyme-producing medium for producing aspartase microorganisms

[0048] Nutrients are added to the supernatant of the ...

Embodiment 3

[0059] The present embodiment is the same as the method, strain, and source of fumaric acid fermentation broth in Embodiment 1, but the conditions are changed.

[0060] (1) Preparation of enzyme-producing medium for producing aspartase microorganisms

[0061] Nutrients are added in the supernatant of fumaric acid fermentation broth: dry corn powder 8g / L, beef extract 4g / L, magnesium sulfate 0.20g / L, potassium dihydrogen sulfate 0.4g / L, pH 7.0 (adjusted with ammonia water);

[0062] (2) Culture of Enriched Aspartase Cells

[0063] Take a ring of well-grown slant seeds in a 250mL shake flask containing 30mL of the above-mentioned enzyme-producing medium, place it on a shaker with a temperature of 37°C and a rotation speed of 180r / min, and culture it with shaking for 14 hours to obtain a seed liquid; 10% (v / v) of the inoculum was transferred to the enzyme-producing medium for expansion cultivation at a temperature of 37° C., ventilation of 0.7 vvm, stirring speed of 150 r / min, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com