Method for preparing flake alpha-Al2O3 granular powder

A granular powder and sheet-like technology, which is applied in the field of preparation of inorganic materials, can solve problems such as polluting the furnace body, polluting the environment, and high energy consumption, and achieves the effects of low cost, simple processing process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preferred preparation method of the present invention is to prepare the soluble inorganic salt solution of aluminum into an aqueous solution, and then add an appropriate amount of alkali to make the pH value of the system greater than 6, filter out aluminum hydroxide, dry it after washing, and grind it into fine powder, and then add the fine powder after grinding into the potassium sulfate aqueous solution with a concentration of 0.001-0.5mol / L, wherein the molar ratio of potassium sulfate to aluminum hydroxide is 5-15, and the The mixed powder of aluminum hydroxide and potassium sulfate is obtained by drying under the conditions, and the mixed powder is calcined at 850-1050° C. for 2-5 hours, and the calcined product is washed with water to remove the potassium sulfate, and then dried.

[0023] The alkali that the present invention adds is preferably ammoniacal liquor.

Embodiment 1

[0026] First, distilled water and Al(NO 3 ) 3 9H 2O configure the solution with aluminum ion concentration of 0.1mol / L, then slowly add 3mol / L ammonia water dropwise into the prepared solution until the pH value of the solution is 9. The obtained aluminum hydroxide was filtered and washed well 8 times with distilled water and then 2 times with alcohol. The aluminum hydroxide wet gel was placed in an oven and dried at 80° C. to obtain the aluminum hydroxide xerogel. Grind aluminum hydroxide dry gel into fine powder, and add the fine powder to potassium sulfate aqueous solution to obtain a suspension, wherein the molar ratio of potassium sulfate to aluminum hydroxide is 6, stir the suspension thoroughly, and dry it in a water bath at 80°C A mixed powder of aluminum hydroxide and potassium sulfate was obtained. Place the mixed powder in Al 2 o 3 In a crucible, calcined at 900°C for 2 hours, the reaction product was washed with water several times to remove potassium sulfate...

Embodiment 2

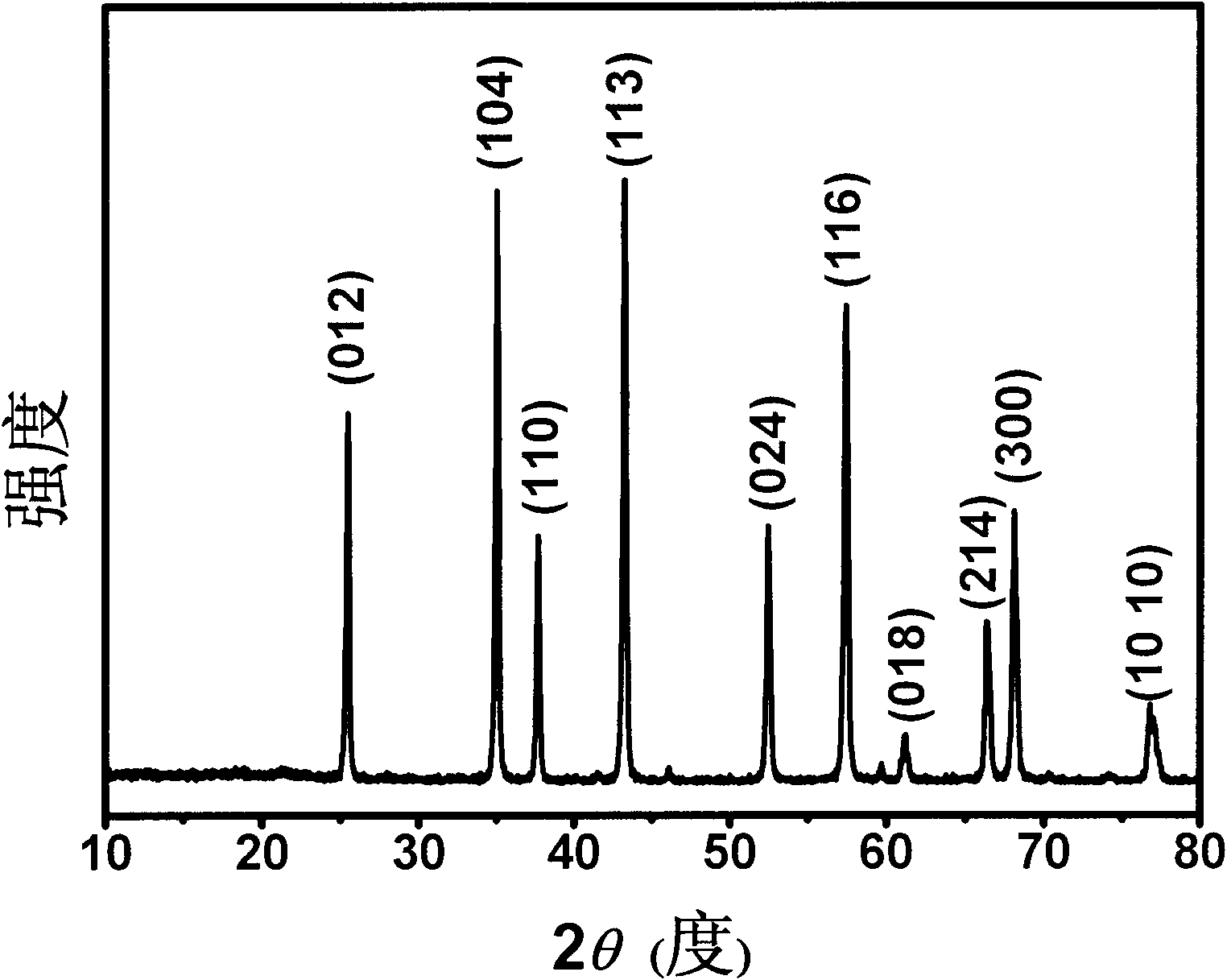

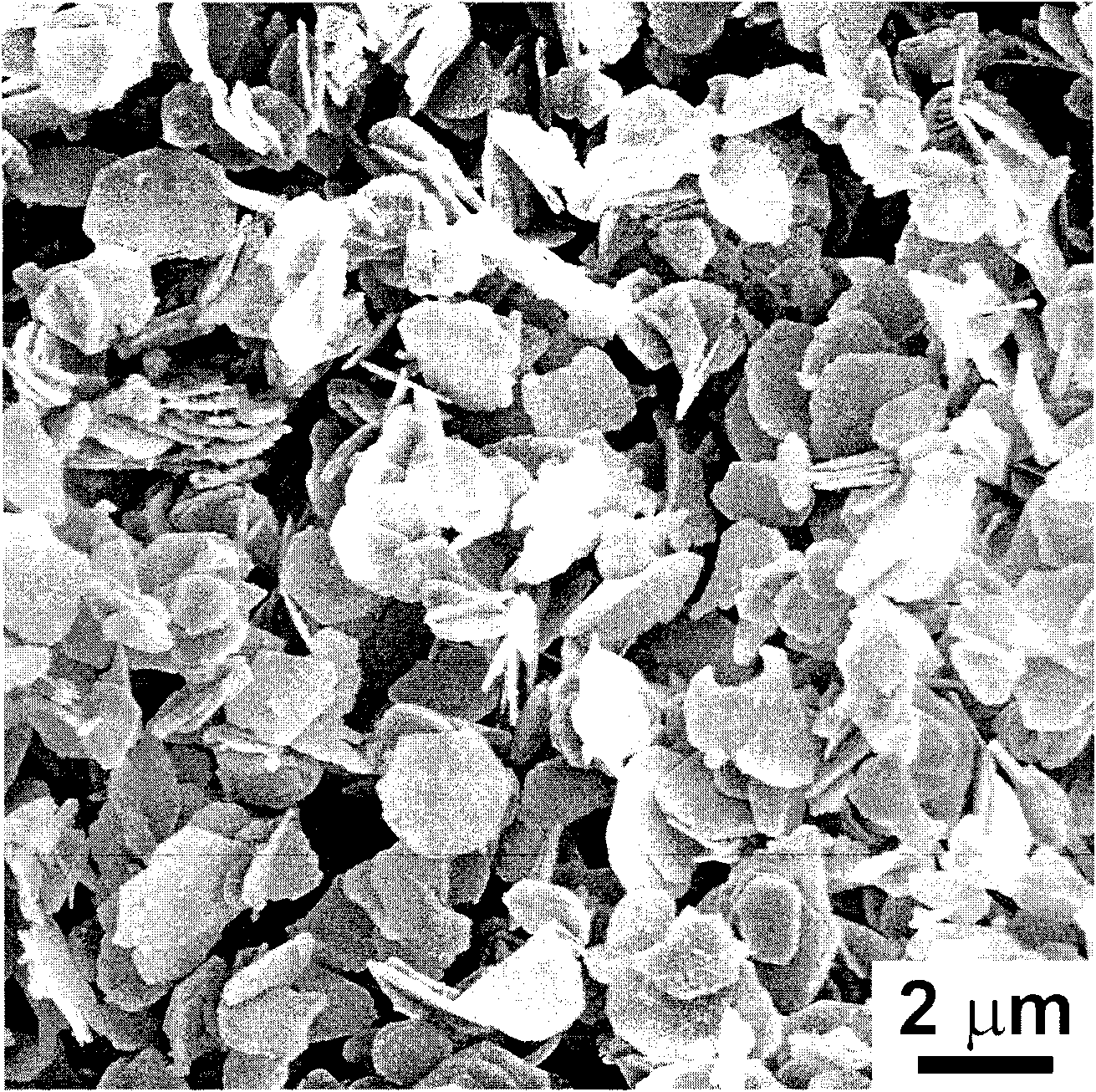

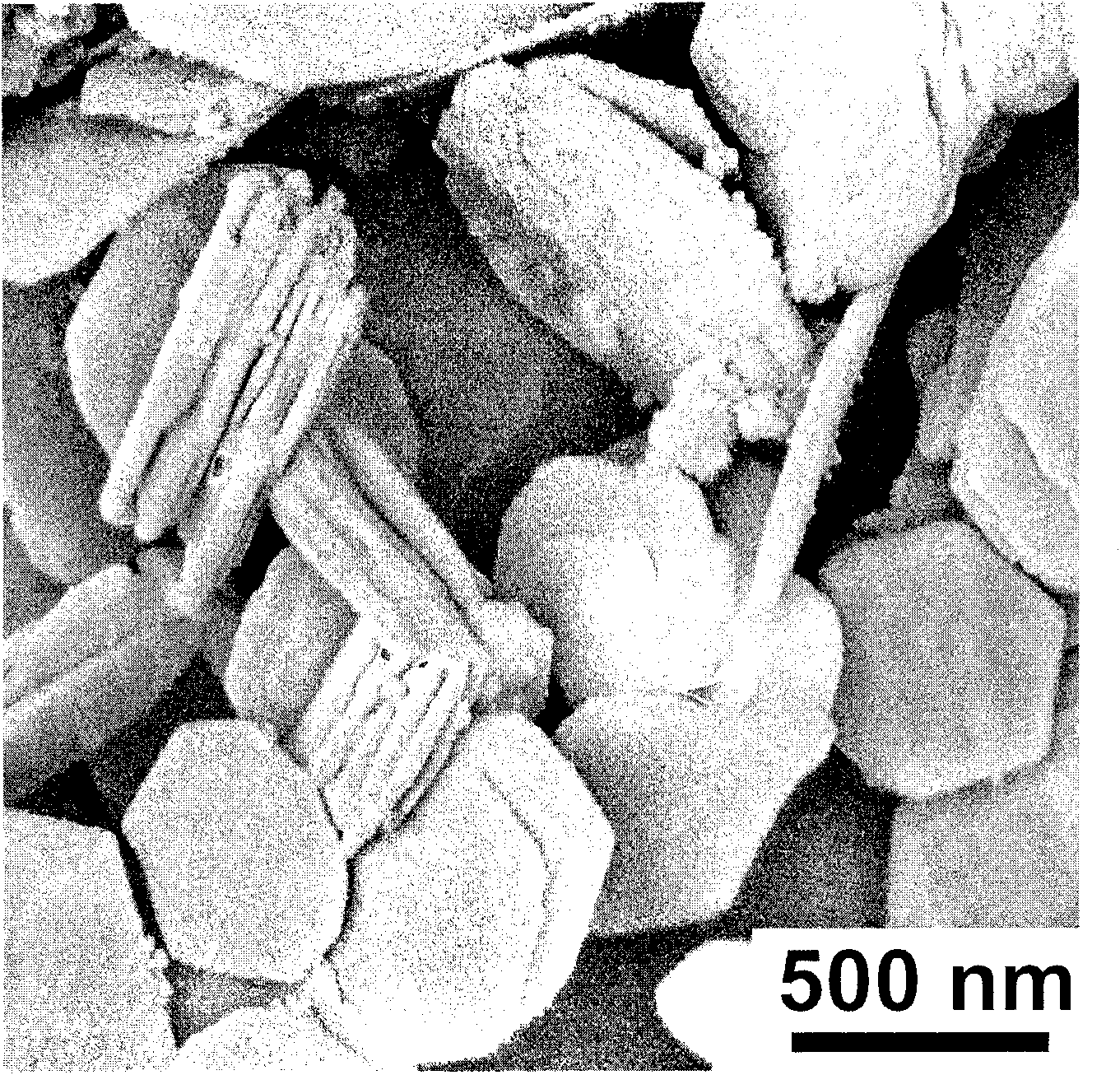

[0028] First, distilled water and Al(NO 3 ) 3 9H 2 O Prepare a solution with an aluminum ion concentration of 0.1 mol / L, and then add α-Al with a particle size of about 50 nm to the solution 2 o 3 Seed. The amount added is that the prepared aluminum hydroxide is completely decomposed into Al 2 o 3 5 wt% of the theoretical total. will be added with α-Al 2 o 3 The aluminum nitrate solution of the seed crystal was placed in an ultrasonic cleaner for 10 minutes so that the α-Al 2 o 3 The seeds are well dispersed into the solution. Subsequently, 3 mol / L ammonia water was added dropwise to the solution to prepare aluminum hydroxide. Subsequent technical process is completely identical with embodiment 1. The prepared flaky α-Al 2 o 3 The X-ray diffraction spectrum of the granular powder and figure 1 same. image 3 For the prepared flake α-Al 2 o 3 Scanning electron micrographs of the particles. Flake α-Al 2 o 3 The particles have an average diameter of 400 nm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com