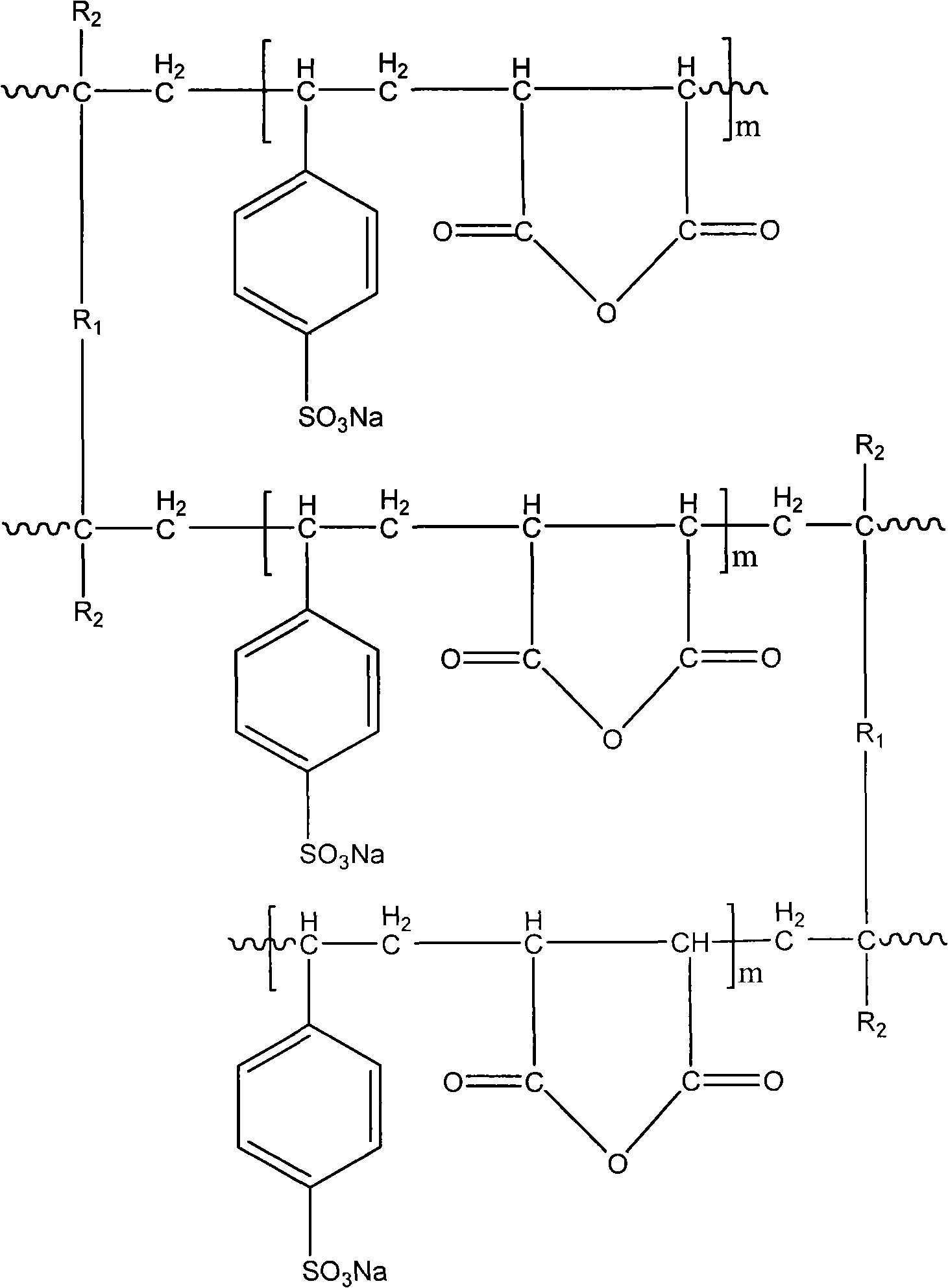

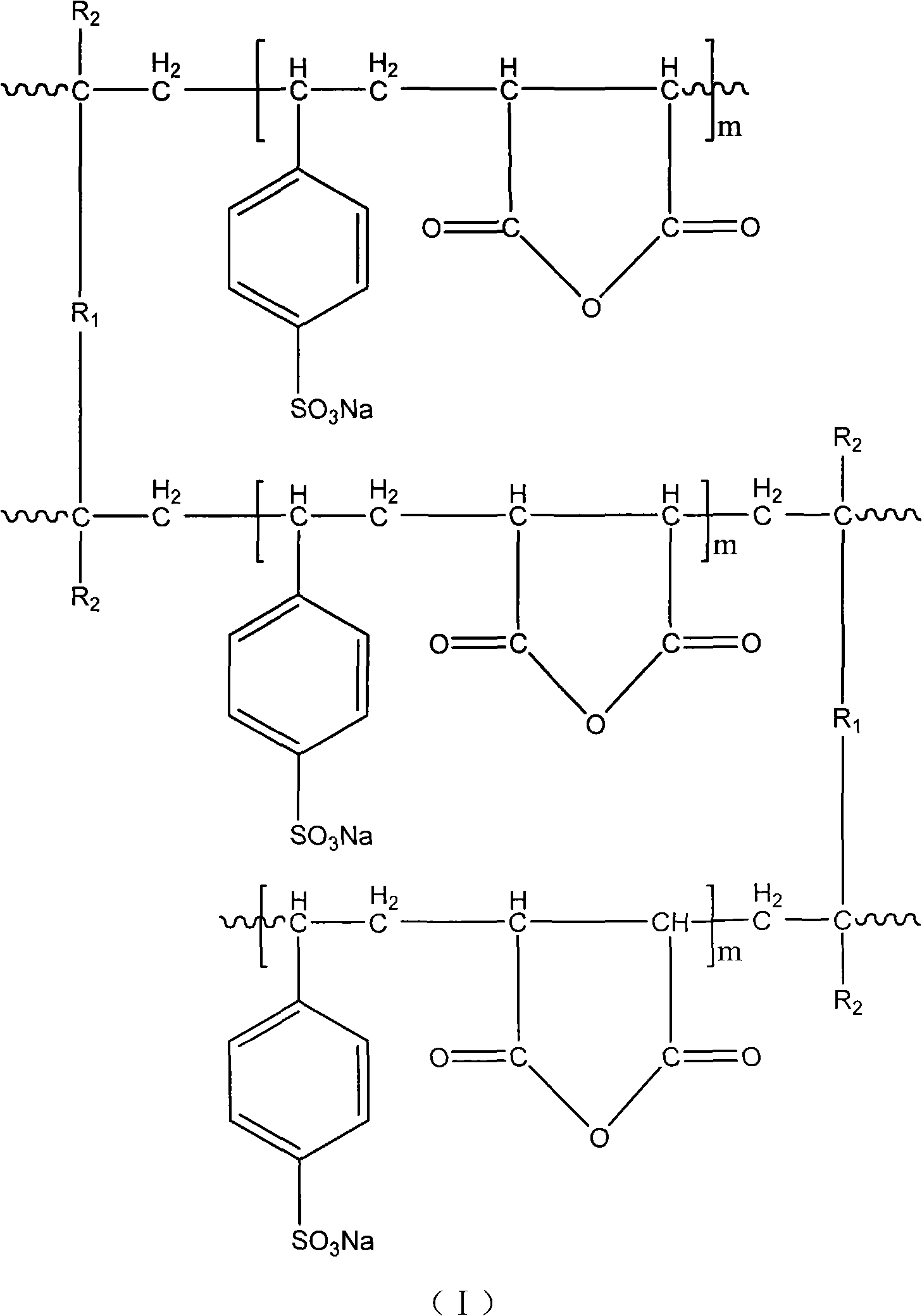

Crosslinking sodium p-styrenesulfonate-maleic anhydride high polymer and photopolymerization preparation method thereof

A technology of sodium styrene sulfonate and maleic anhydride, which is applied in the field of ultraviolet light polymerization and high polymers, and can solve the problems of slow reaction speed and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: Dispersion polymerization method under ultraviolet light polymerization technology

[0020] Add 2.06g of sodium styrene sulfonate and 0.98 g of maleic anhydride monomer to 100 mL of dimethyl sulfoxide reaction solvent, then add 0.3 g of photoinitiator benzoin (BE), 0.46 g of crosslinking agent divinyl Benzene and 0.55g dispersant polyvinylpyrrolidone are dissolved by ultrasonication. After complete dissolution, continue ultrasonication for 5 minutes, and then place the mixed solution in a light intensity of 10mW / cm 2 react under an ultraviolet light source for 10 minutes to obtain a dispersion system of cross-linked polymer microspheres, and then centrifuge to obtain cross-linked polymer solid microspheres.

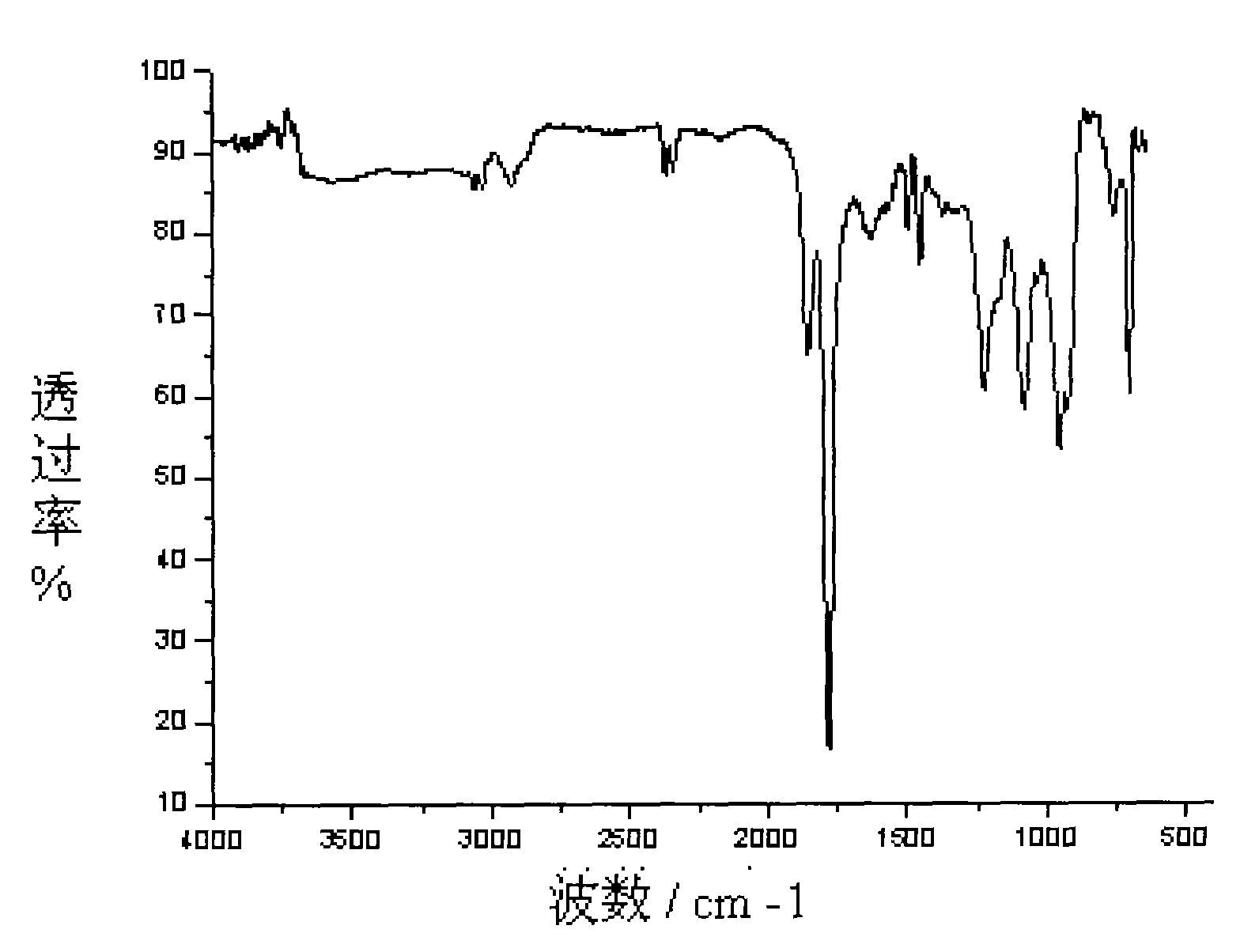

[0021] The product was analyzed by infrared (infrared spectrum as figure 1 Shown), 1853.7cm -1 , 1779.3cm -1 Left and right are the characteristic peaks of carboxyl groups in maleic anhydride; 3056cm -1 、3087cm -1 The band at is the stretching vi...

Embodiment 2

[0022] Embodiment 2: Dispersion polymerization method under ultraviolet light polymerization technology

[0023] The sodium styrene sulfonate of 20.6g and 9.8g maleic anhydride monomer are joined in the 100mL N-methylpyrrolidone reaction solvent, then add 0.10g photoinitiator α, α'-dimethyl benzyl ketal ( Namely 651), 0.15g cross-linking agent ethylene glycol diacrylate and 10.4g dispersant hydroxymethyl cellulose are ultrasonically dissolved with an ultrasonic instrument, and after being completely dissolved, continue ultrasonication for 20 minutes, then place the mixed solution When the light intensity is 300mW / cm 2 React for 1 minute under an ultraviolet light source to obtain a dispersion system of cross-linked polymer microspheres, and then obtain cross-linked sodium styrene sulfonate-maleic anhydride polymer microspheres through centrifugation.

Embodiment 3

[0024] Embodiment 3: Dispersion polymerization method under ultraviolet light polymerization technique

[0025] Add 10.3g of sodium styrene sulfonate and 4.9g of maleic anhydride monomer to 100mL of N, N dimethylformamide reaction solvent, then add 0.08g of photoinitiator α, α'-diethoxyphenyl ethyl Ketone (DEAP), 0.25g cross-linking agent dipropylene glycol dimethacrylate and 3.45g dispersant hydroxypropyl cellulose were ultrasonically dissolved with an ultrasonic instrument. After being completely dissolved, the ultrasonic wave was continued for 10 minutes, and then the mixed solution Placed at a light intensity of 100mW / cm 2 The reaction was carried out under an ultraviolet light source for 6 minutes to obtain a dispersion system of cross-linked polymer microspheres, and then centrifuged to obtain cross-linked sodium styrene sulfonate-maleic anhydride polymer microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com