Method for treating coking wastewater

A treatment method and technology for coking wastewater, applied in chemical instruments and methods, biological water/sewage treatment, multi-stage water/sewage treatment, etc. Complicated chemical bed structure and other problems, to achieve stable treatment effect, strong impact resistance, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

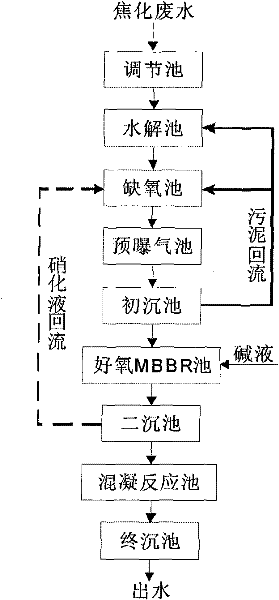

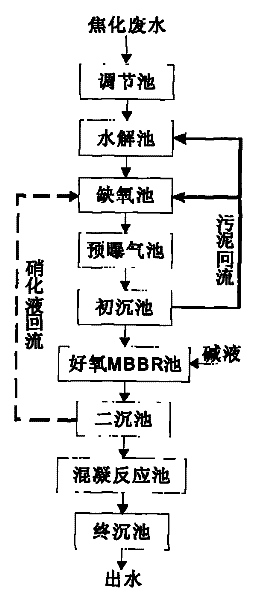

[0030] like figure 1, During the wastewater treatment process of a coking plant, the influent COD is 800-1300mg / L, ammonia nitrogen is 60-100mg / L, and pH is 7.5-8.5. The waste water enters the hydrolysis pool after adjusting the water quantity and quality in the regulating pool. The sludge concentration in the hydrolysis pool is 5500-7000mg / L, and the inside is filled with biological rope filler. Upflow water distribution is adopted, and the hydraulic retention time is 10h. The effluent from the hydrolysis tank enters the anoxic tank from the lower part, and a mechanical stirring device is installed in the anoxic tank, the sludge concentration is 4000-5000mg / L, and the hydraulic retention time is 13h. After being treated in the anoxic tank, the wastewater flows into the pre-aeration tank, and the pre-aeration tank is filled with biological rope filler, made of polypropylene, with a diameter of 100 mm, aerated by a perforated tube at the bottom of the tank, and the concentrati...

Embodiment 2

[0033] like figure 1 , During the wastewater treatment process of a coking plant, the influent COD is 1000-2000mg / L, ammonia nitrogen is 80-220mg / L, and pH is 7.0-8.5. The waste water enters the hydrolysis pool after adjusting the water quantity and quality in the regulating pool. The sludge concentration in the hydrolysis pool is 6000-7500mg / L, and the inside is filled with biological rope filler. Type water distribution, the hydraulic retention time is 12h. The effluent from the hydrolysis tank enters the anoxic tank from the lower part. A mechanical stirring device is installed in the anoxic tank. The sludge concentration is 4000-5500mg / L, and the hydraulic retention time is 16h. After being treated in the anoxic tank, the wastewater flows into the pre-aeration tank, and the pre-aeration tank is filled with biological rope filler, made of polypropylene, with a diameter of 45mm, aerated by a perforated tube at the bottom of the tank, and the concentration of dissolved oxyge...

Embodiment 3

[0036] like figure 1 , During the wastewater treatment process of a coking plant, the influent COD is 1500-2500mg / L, ammonia nitrogen is 70-210mg / L, and pH is 7.5-9.0. The waste water enters the hydrolysis pool after adjusting the water volume and quality in the regulating pool. The sludge concentration in the hydrolysis pool is 6000-8000mg / L, and the interior is filled with biological rope fillers. The rope core is surrounded by ring-shaped thin fibers made of nylon, vinylon and polypropylene. The diameter is 50mm, and the upper flow water distribution is adopted, and the hydraulic retention time is 13h. The effluent from the hydrolysis tank enters the anoxic tank from the lower part. A mechanical stirring device is installed in the anoxic tank. The sludge concentration is 5000-6000mg / L, and the hydraulic retention time is 17.5h. After being treated in the anoxic tank, the wastewater flows into the pre-aeration tank, and the pre-aeration tank is filled with biological rope f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com