High-performance zinc oxide composite ceramic voltage dependent resistor material and preparation method

A technology of varistors and composite ceramics, applied in the direction of varistors, varistor cores, etc., can solve the problems of changing varistors, reducing the surge absorption capacity of varistors, and destroying the micro-resistance structure of resistor sheets, etc. , to achieve the effect of increasing the potential gradient, realizing the miniaturization of the volume, and enriching the source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method comprises the following process steps and contents:

[0023] 1) Weigh raw materials according to the composition designed for the praseodymium-based zinc oxide varistor material, and add 0-10% (mass fraction) of dispersant and adhesive.

[0024] 2) Mix the claimed powder, dispersant and binder with zirconia balls and deionized water in a polyurethane ball mill tank, grind and mix them evenly on a high-energy ball mill.

[0025] 3) In a drying oven, the ground and mixed slurry is kept at a temperature of 40-250° C. for 12-96 hours and dried.

[0026] 4) Grinding the dried powder, and selecting a sieve with a suitable aperture for sieving.

[0027] 5) Dry press the ground powder in a mold with specified specifications and shapes.

[0028] 6) Sintering the praseodymium-based zinc oxide varistor ceramic green body according to a preset sintering system.

[0029] 7) Coating the praseodymium-based zinc oxide varistor ceramic sintered body with silver...

Embodiment 1

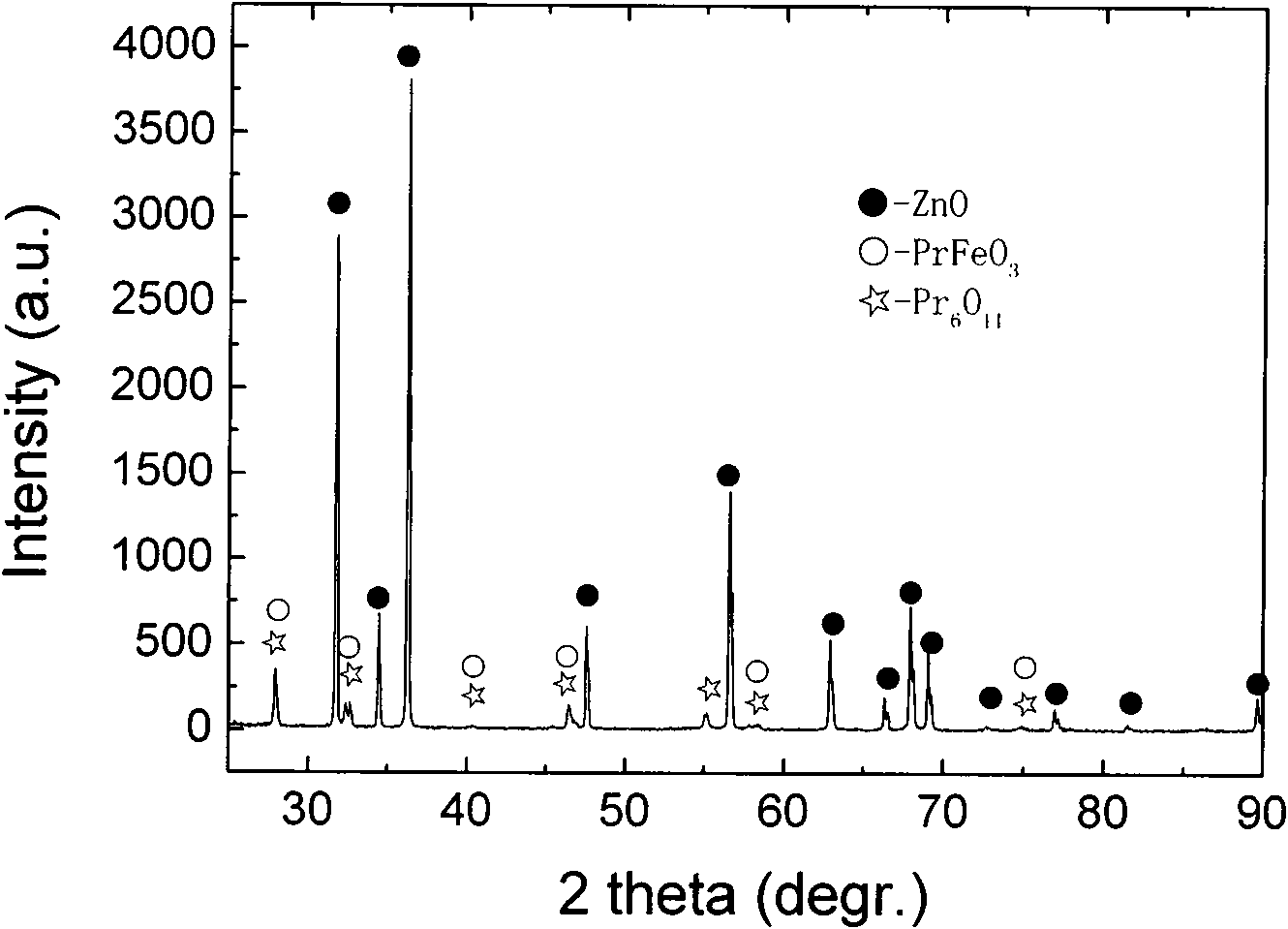

[0033] Commercially available analytically pure ZnO, Pr 6 o 11 , CoO, Cr 2 o 3 , Fe 2 o 3 Mixing is carried out in molar ratio, and the proportioning relationship is ZnO:Pr 6 o 11 :CoO:Cr 2 o 3 : Fe 2 o 3 =98:0.7:1.0:0.2:0.1, and add 5% (mass fraction) polyvinyl alcohol and 3% (mass fraction) Davon C, put into poly In the polyurethane ball mill tank, after ball milling on a high-energy ball mill for 48 hours, dry in the air and in a drying oven at 130°C for 72 hours, after grinding, dry press molding, sinter at 1300°C for 4 hours, and keep warm at 700°C 2 hours were made of silver electrodes. The resulting material is a typical two-phase structure, including a zinc oxide phase and a phase mainly composed of praseodymium oxide (see figure 1 ), the grain size is uniform (see figure 2 ). Zinc oxide composite ceramic varistor material made in this embodiment, 1mA / cm 2 When the potential gradient is 570V / mm, 1 / log(E 10mA / cm2 / E 1mA / cm2 ) when the nonlinear coeffic...

Embodiment 2

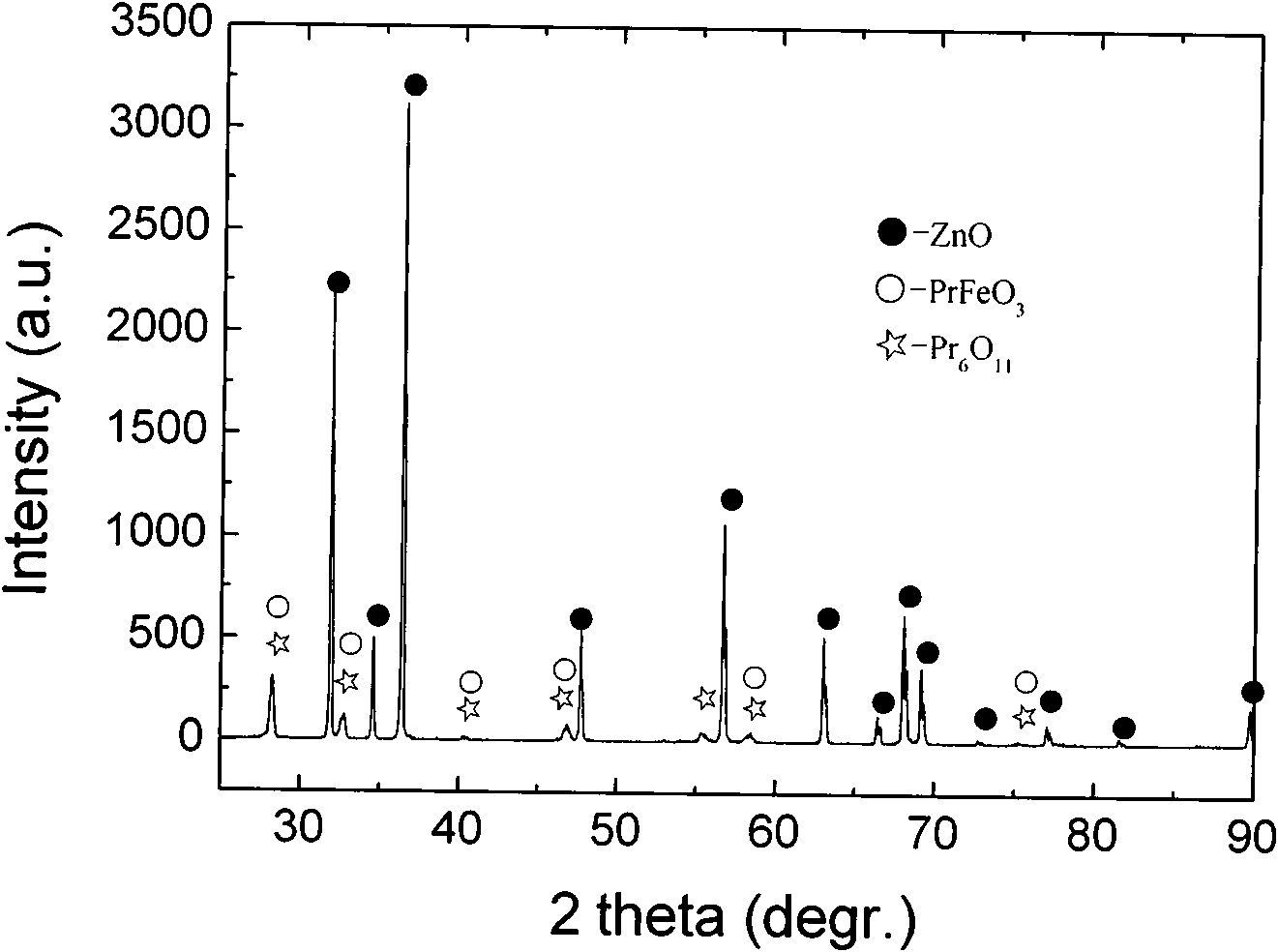

[0035] Commercially available analytically pure ZnO, Pr 6 o 11 , CoO, Cr 2 o 3 , Fe 2 o 3 、WO 3 Mixing is carried out in molar ratio, and the proportioning relationship is ZnO:Pr 6 o 11 :CoO:Cr 2 o 3 : Fe 2 o 3 : WO 3=97: 1.5: 1.0: 0.4: 0.05: 0.05, and add 1% (mass fraction) polyvinyl alcohol and 0.05% (mass fraction) Davon C, press 1: 4: 2 powder: zirconium ball: deionized water mass ratio Put it into a polyurethane ball mill tank, mill it on a high-energy ball mill for 48 hours, dry it in air and in a drying oven at 130°C for 24 hours, dry press it after grinding, sinter at 1300°C for 2 hours, and dry it at 700°C The electrodes were made of silver under incubation for 2 hours. The resulting material is a typical two-phase structure, including a zinc oxide phase and a phase mainly composed of praseodymium oxide (see image 3 ), the grain size is uniform (see Figure 4 ). Zinc oxide composite ceramic varistor material made in this embodiment, 1mA / cm 2 When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com