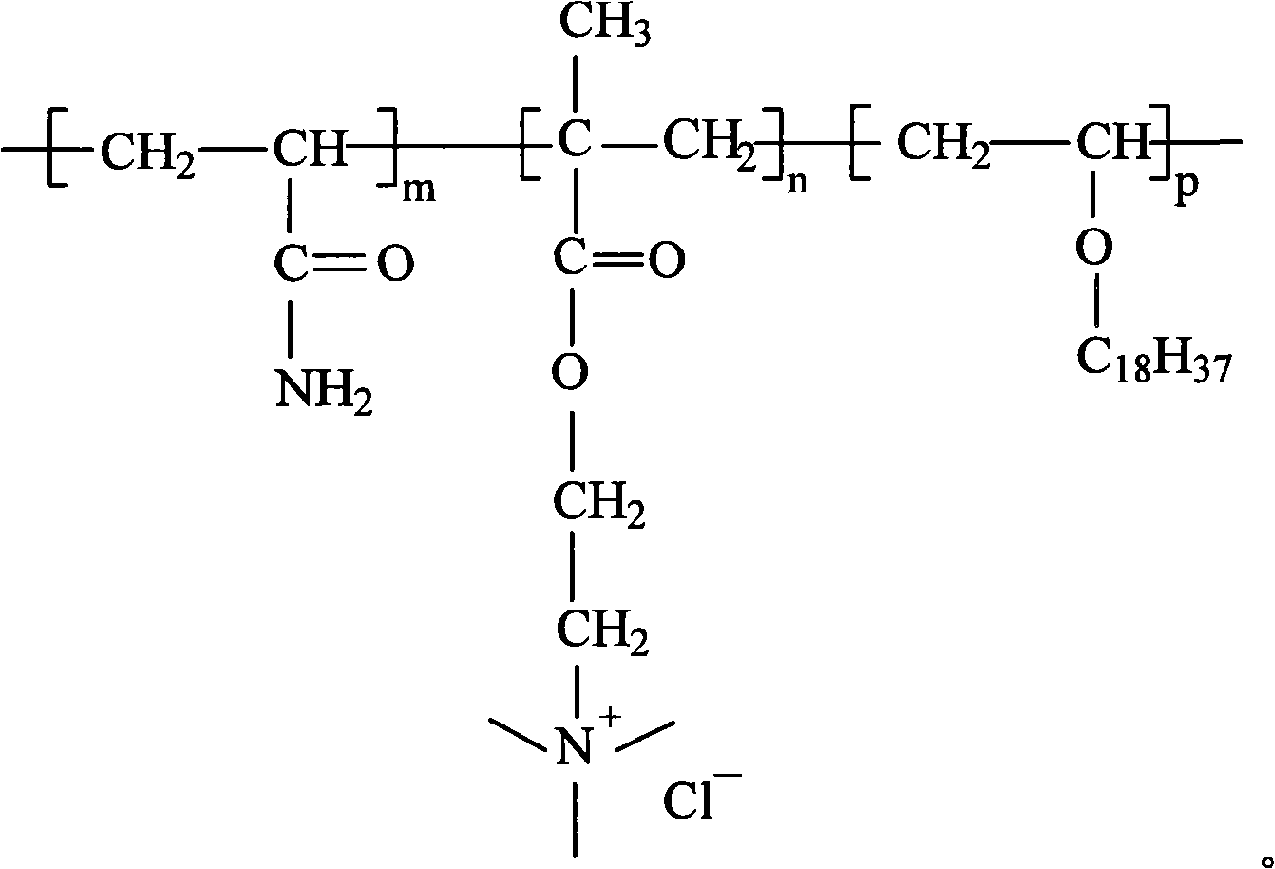

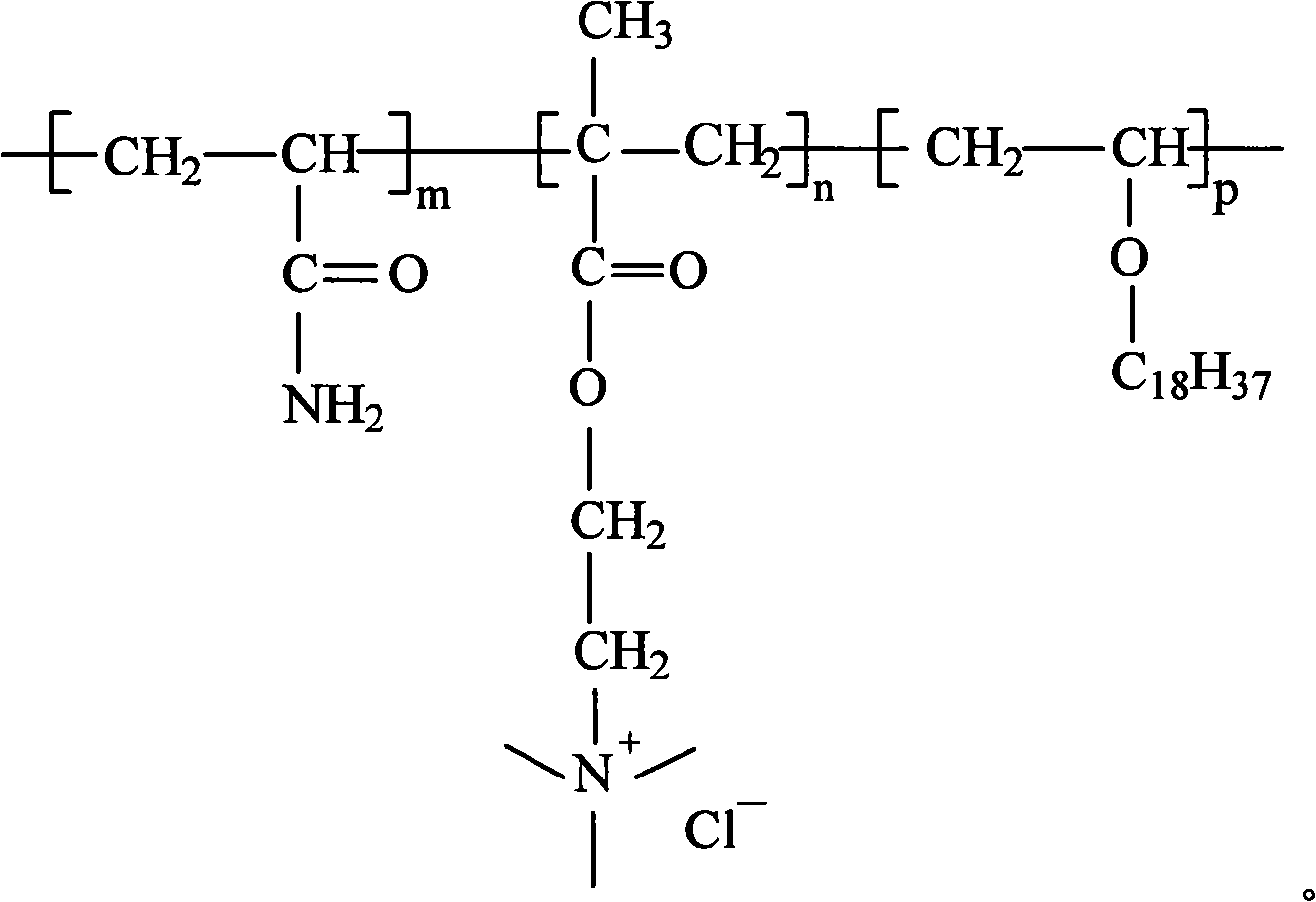

Hydrophobic cation polymeric flocculant and preparation method and application thereof

A polymer flocculant and cation technology, which is used in dewatering/drying/concentrating sludge treatment, etc., can solve the problems such as the inability to effectively improve the dewatering rate of the sediment, the difficulty in drying the dredged sediment quickly, and the poor hydrophobicity. , to achieve the effect of wide range of use, good flocculation effect and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

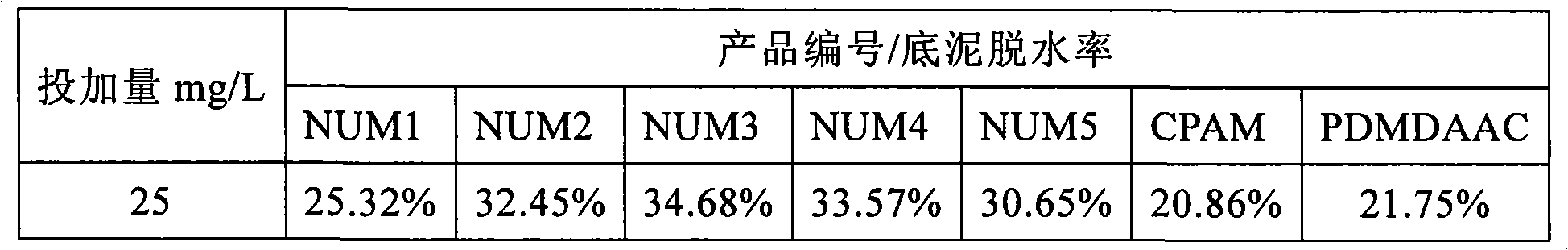

Embodiment 1

[0023] Add acrylamide, methacryloyloxyethyltrimethylammonium chloride, cetyltrimethylammonium bromide, urea and deionized water into a four-necked flask, stir to raise the temperature and add octadecylvinyl Ether, add initiator (ammonium persulfate, sodium bisulfite mass ratio of 2:1 mixture) after strong stirring, heat preservation reaction for 4 hours to prepare hydrophobic cationic polymer flocculant, acrylamide, methyl The total amount of acryloyloxyethyltrimethylammonium chloride and octadecyl vinyl ether is recorded as the total monomer amount, wherein the acrylamide content accounts for 89.5mol% of the total monomer amount, and the methacryloyloxyethyl trimethyl ammonium The content of methyl ammonium chloride accounts for 10mol% of the total amount of monomers, the content of cetyltrimethylammonium bromide accounts for 6wt% of the total amount of monomers, the content of urea accounts for 2wt% of the total amount of monomers, the total amount of monomers The weight rat...

Embodiment 2

[0031] Add acrylamide, methacryloyloxyethyltrimethylammonium chloride, cetyltrimethylammonium bromide, urea, and deionized water into a four-necked flask, stir to raise the temperature, and add stearyl acrylate. After stirring, add an initiator (a mixture of ammonium persulfate and sodium bisulfite with a mass ratio of 2:1), and keep warm for 4 hours to prepare a hydrophobic cationic polymer flocculant. The acrylamide, methacryloxy The total amount of ethyltrimethylammonium chloride and octadecyl vinyl ether is recorded as the total monomer amount, wherein the acrylamide content accounts for 86.5mol% of the total monomer amount, and methacryloyloxyethyl trimethyl chloride The ammonium chloride content accounts for 10mol% of the total monomer amount, the cetyltrimethylammonium bromide content accounts for 6wt% of the total monomer amount, and the urea content accounts for 2wt% of the total monomer amount. The total monomer amount and deionized The weight ratio of water is 20:80...

Embodiment 3

[0039] Add acrylamide, methacryloyloxyethyltrimethylammonium chloride, cetyltrimethylammonium bromide, urea, and deionized water into a four-necked flask, stir to raise the temperature, and add stearyl acrylate. After stirring, add an initiator (a mixture of ammonium persulfate and sodium bisulfite with a mass ratio of 2:1), and keep warm for 4 hours to prepare a hydrophobic cationic polymer flocculant. The acrylamide, methacryloxy The total amount of ethyltrimethylammonium chloride and octadecyl vinyl ether is recorded as the total monomer amount, wherein the acrylamide content accounts for 56.5mol% of the total monomer amount, and methacryloyloxyethyl trimethyl chloride The ammonium chloride content accounts for 40mol% of the total monomer amount, the cetyltrimethylammonium bromide content accounts for 6wt% of the total monomer amount, and the urea content accounts for 2wt% of the total monomer amount. The total monomer amount and deionized The weight ratio of water is 20:80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com