Hydroximated water-soluble polyelectrolyte inverse microemulsion and preparation process thereof

An inverse microemulsion, water-soluble polymer technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, separation methods, etc. Reduce the composition and other problems, to achieve the effect of fast dissolution, good freeze-thaw stability, and lower liquid-solid ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

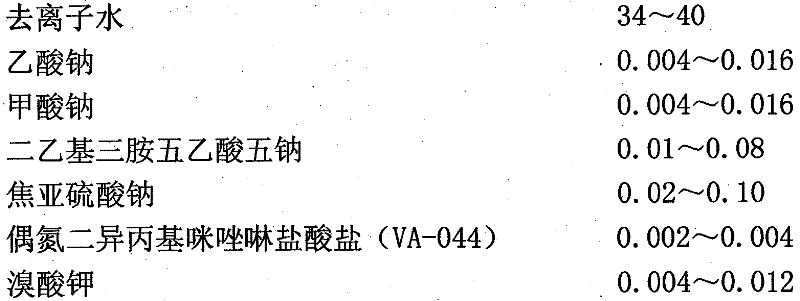

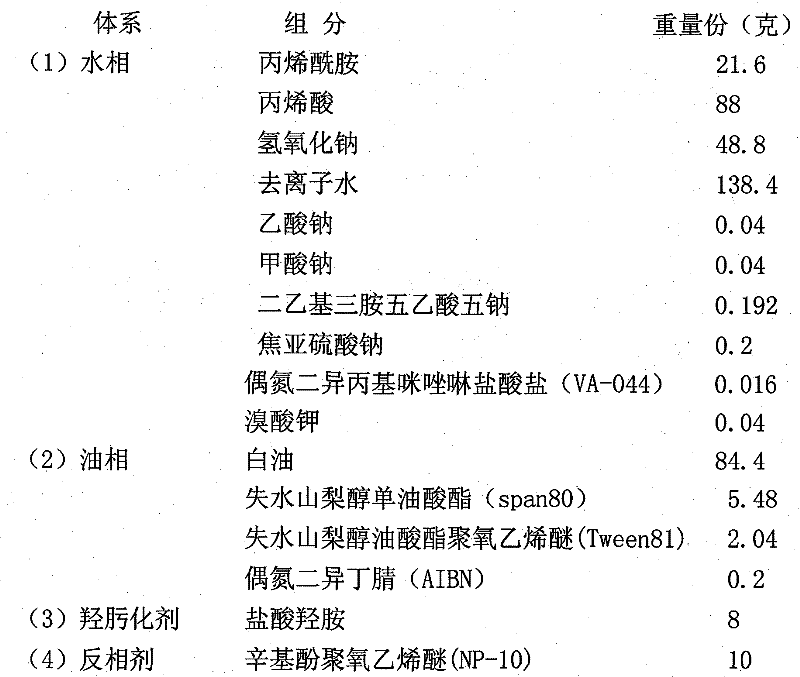

[0023] 1. Emulsion formula:

[0024]

[0025] 2. Preparation process:

[0026] (1) Get 73.2 grams of water successively and sodium hydroxide is made into a 40% solution by mass percentage for stand-by; Get 9.8 grams of water and sodium metabisulfite is made into a 2% solution by mass percentage for stand-by; Get 8 grams of water and make azobis Isopropyl imidazoline hydrochloride (VA-044) was made into a 0.2% solution by mass percentage for use; 10 grams of water was made into a 0.4% solution by mass percentage with potassium bromate for use;

[0027] (2) Add the remaining 37.4 deionized water into the polymerization reactor, and add the measured acrylamide (AM) and acrylic acid (AA) successively under the stirring state with a rotation speed of 200 rpm, until they are completely dissolved. Cool the monomer mixture to below 15°C, slowly add dissolved sodium hydroxide solution, and control the solution temperature at 17-20°C. After adding the sodium hydroxide solution, add...

Embodiment 2

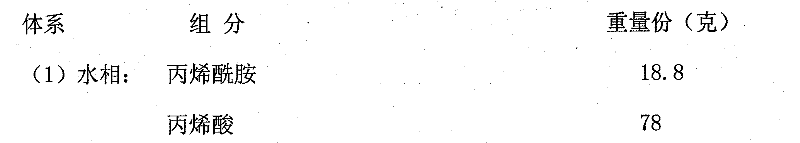

[0031] 1. Emulsion formula:

[0032]

[0033]

[0034] 2. Preparation process:

[0035] (1) get 64.2 grams of water successively and sodium hydroxide is made into the solution of 40% by mass percent for stand-by; Get the water of 8.82 grams and sodium pyrosulfite is made into the solution of 2% by mass percent for stand-by; Get 7 grams of water and make the solution of even Nitrogen diisopropyl imidazoline hydrochloride (VA-044) is made into a solution of 0.2% by mass percent for stand-by; 8.8 grams of water is made into a solution of 0.4% by mass percent of potassium bromate for stand-by;

[0036] (2) Add the remaining 68.18 g of deionized water into the polymerization reactor, and add in the measured acrylamide (AM) and acrylic acid (AA) in sequence at a stirring speed of 200 rpm until they are completely dissolved. Cool the body mixture to below 15°C, slowly add the dissolved sodium hydroxide solution, and control the solution temperature at 17-20°C. After adding th...

Embodiment 3

[0040] 1. Emulsion formula:

[0041]

[0042]

[0043] 2. Preparation process:

[0044] (1) get 49.2 kilograms of water successively and sodium hydroxide is made into the solution of 40% by mass percentage for stand-by; Get 9.8 kilograms of water and sodium metabisulfite is made into the solution of 2% by mass percent for stand-by; Get 8 kilograms of water and make the solution of even Nitrogen diisopropyl imidazoline hydrochloride (VA-044) is made into a solution of 0.2% by mass percent for stand-by; 10 kilograms of water is made into a solution of 0.4% by mass percent of potassium bromate for stand-by;

[0045] (2) Add the remaining 69.04 kg of deionized water into the polymerization reactor (glass-lined or stainless steel), and add the measured acrylamide (AM) and acrylic acid (AA) in turn under the stirring state at a speed of 60 rpm. , until completely dissolved, the temperature of the monomer mixture is lowered to below 15°C, and the dissolved sodium hydroxide sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com