Method and equipment for continuous solid-state fermentation and gas-stripping heat-pump coupling separation of product

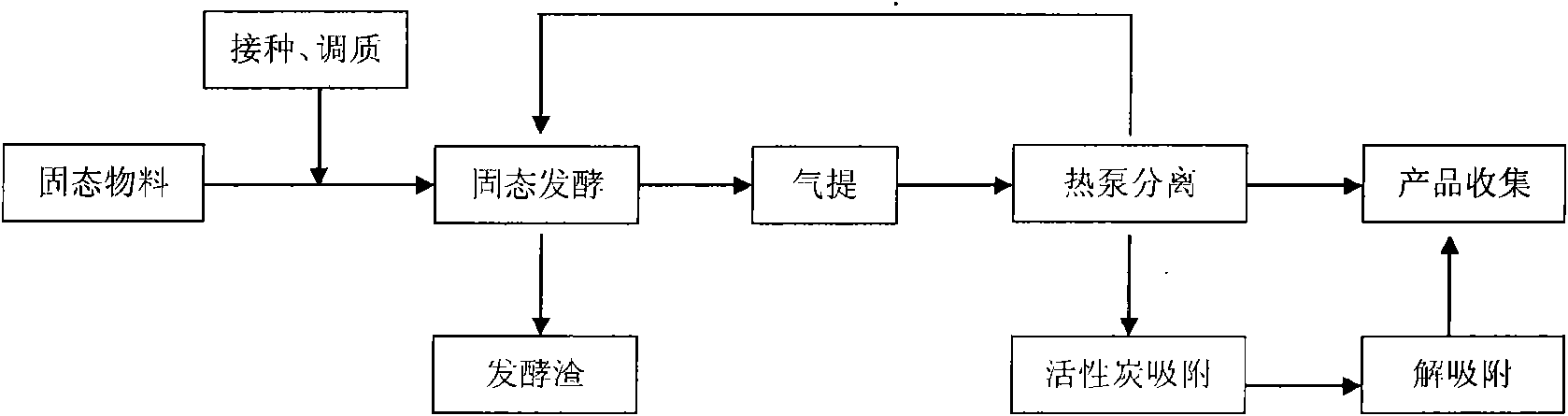

A technology of solid-state fermentation and fermentation products, which is applied in the field of continuous solid-state fermentation and product gas-lifting heat pump coupling separation, can solve the problems of reducing feedback inhibition of fermentation products, inability to realize continuous feeding and discharging, and high energy consumption for product separation, and achieves a solution The control of mass transfer and heat transfer, the high efficiency and unity of energy quality and quantity, and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

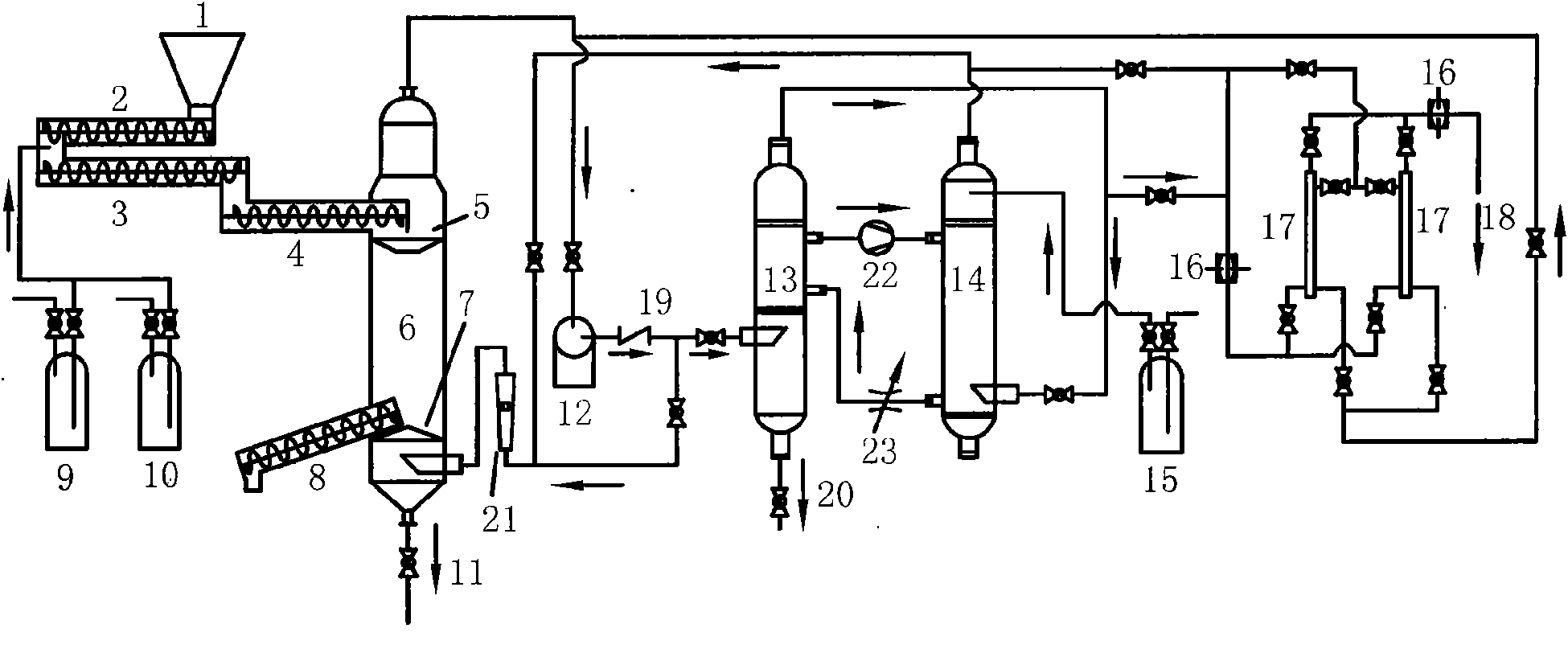

Embodiment 1

[0047] Use crushed sweet sorghum stalks with a water content of 80%, a total sugar content of 13% to 14%, and a reducing sugar content of 6% to 7% as raw materials, feed 120L through a screw conveyor, and inoculate Angel high active dry yeast Saccharomyces cerevisiae at the same time (inoculum size 0.5%), and add nutrients (0.5% (NH 4 ) 2 SO 4 , 0.5% CaCl 2 ), adjust the pH to be about 5.0, and use CO 2 Replace the air in the system, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 35°C, the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, the crude ethanol was collected from the bottom of the heat pump evaporator at intervals, co-fermented for 24 hours, and finally a total of 7600ml of ethanol solution was collected, with an ethanol volume fraction of 24.0%, and a total ethanol yield of 5.09g / 100g sweet sorghum stalks, reaching the theoretical yield of ethanol 78.5%, the total residual...

Embodiment 2

[0049] Use crushed sweet sorghum stalks with a water content of 80%, a total sugar content of 13% to 14%, and a reducing sugar content of 6% to 7% as raw materials, feed 120L through a screw conveyor, and inoculate Angel high active dry yeast Saccharomyces cerevisiae at the same time (inoculum size 0.5%), and add nutrients (0.5% (NH 4 ) 2 SO 4 , 0.5% CaCl 2 ), adjust the pH to about 5.0, replace the air in the system with CO2 after the feed is completed, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 35°C, and the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, collect crude ethanol from the bottom of the heat pump evaporator at intervals, and open the four-stage screw conveyor at the same time to continuously feed and discharge materials after the fermentation starts. The feeding and discharging speeds remain the same, both at 20L / 24h. 180L, a total of 11600ml of ethanol solution was...

Embodiment 3

[0051] With water content 66.5%, the fresh kudzu root of starch content 17.15%, chop into 10~15cm small section, steam explosion treatment 3.5min under the condition of steam pressure 0.8Mpa, feed 120L of steam explosion kudzu root through screw conveyor, feed Simultaneously add glucoamylase (65U / g substrate), inoculate Angelica high activity Saccharomyces cerevisiae (inoculum size 0.5%), and add nutrient salt (0.1% (NH 4 ) 2 SO 4 , 0.1% KH 2 PO 4 ), adjust the pH to be about 5.0, and use CO 2 Replace the air in the system, turn on the fan and heat pump device after the replacement, control the temperature in the fermentation tower at 35°C, the temperature of the heat pump evaporator at 5-10°C, CO 2 Flow 3.6m 3 / h, crude ethanol was collected from the bottom of the heat pump evaporator at intervals, and fermented for 60 hours. Finally, 12500ml of ethanol solution was collected, with a volume fraction of 36%. The total ethanol yield was 9.2g / 100g kudzu root, and the starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com