Method for preparing heaters by chemical vapor infiltration and resin impregnation, carbonization and densification

A chemical vapor infiltration and resin impregnation technology, applied in the direction of heating element materials, can solve the problems of low strength of graphite bolts, low yield, layering defects in the thickness direction, etc., to improve thermal shock resistance and structural stability, improve The ability to resist delamination and improve the effect of anti-scouring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

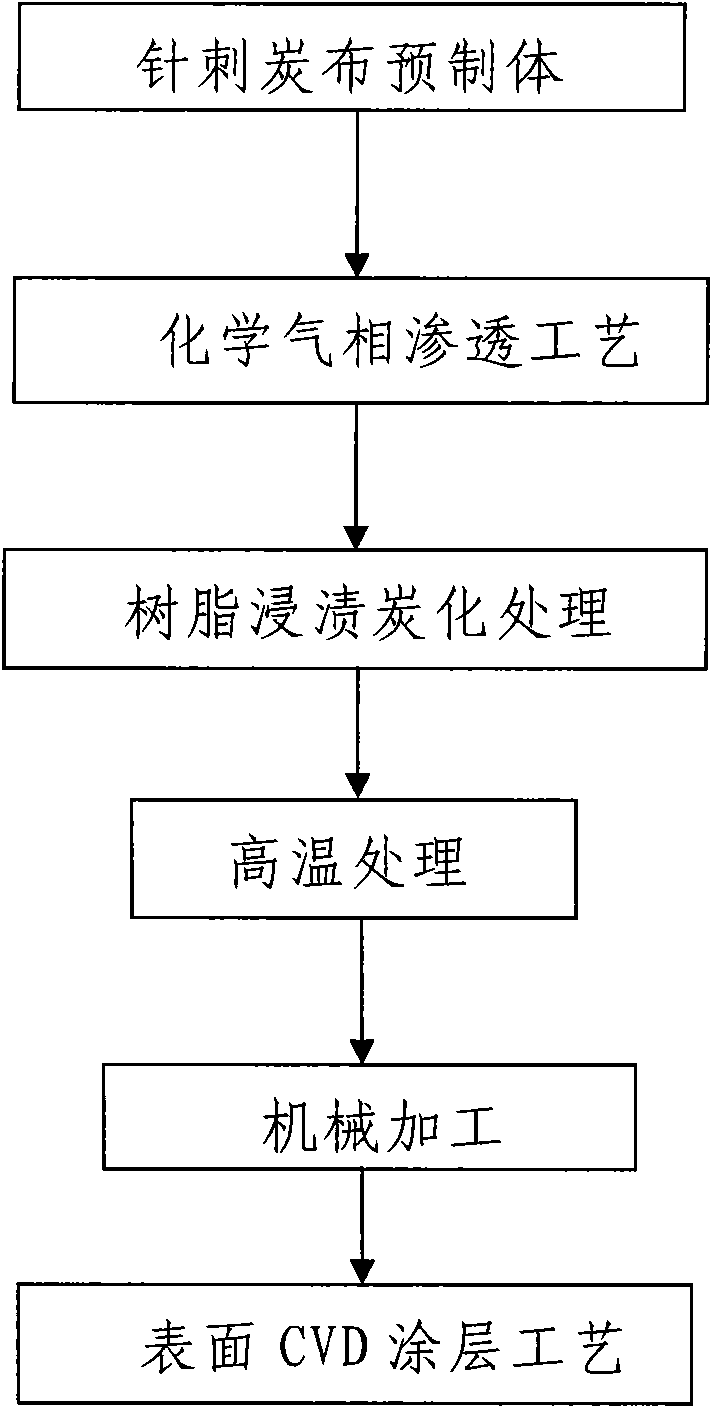

Method used

Image

Examples

Embodiment 1

[0027] (1) Use 12K plain weave carbon cloth and short carbon fiber mesh alternately to form fibers in the plane direction, and adopt the needle punching process to introduce vertical fibers in the thickness direction to make a three-way structure heating element preform, with a needle punch density of 35-40 needles / cm 2 , Its density is 0.45g / cm 3 , Where K represents the number of tows in thousands;

[0028] (2) The chemical vapor infiltration process uses shaping tooling to shape the heating element preform inside and outside to ensure the product size; at 940°C, use propylene as the carbon source gas to perform gas phase infiltration and densification of the preform;

[0029] (3) Resin pressure impregnation carbonization: Step (2) The density of the carbon / carbon heating element product is ≥0.80g / cm 3 At this time, carry out pressure impregnation treatment with furfurone resin, immerse it in the impregnation tank for 3 hours under the pressure of 2.0MPa, and then solidify, the t...

Embodiment 2

[0035] (1) Use 48K twill carbon cloth and short carbon fiber mesh alternately to form fibers in the plane direction, and adopt acupuncture process to introduce vertical fibers in the thickness direction to make a three-way structure heating element preform, with a needle punching density of 25-30 needles / cm 2 , Its density is 0.25g / cm 3 , Where K represents the number of tows in thousands;

[0036] (2) The chemical vapor infiltration process uses shaping tooling to shape the heating element preform inside and outside to ensure the product size; at 850°C, use propylene as the carbon source gas to perform gas phase infiltration and densification of the preform;

[0037] (3) Resin pressure impregnation carbonization: Step (2) The density of the carbon / carbon heating element product is ≥0.80g / cm 3 At this time, carry out pressure impregnation treatment with furfurone resin, immerse it in the impregnation tank for 4 hours under the pressure of 1.5MPa, and then solidify, the treatment te...

Embodiment 3

[0043] (1) Using 6K satin carbon cloth and short carbon fiber mesh alternately to form fibers in the plane direction, and adopting the needle punching process to introduce vertical fibers in the thickness direction to make a three-way structure heating element preform, with a needle punch density of 40 to 45 Needle / cm 2 , Its density is 0.65g / cm 3 , Where K represents the number of tows in thousands;

[0044] (2) The chemical vapor infiltration process uses shaping tooling to shape the heating element preform inside and outside to ensure the product size; at a temperature of 1200°C, natural gas is used as the carbon source gas to perform gas phase infiltration and densification of the preform;

[0045] (3) Resin pressure impregnation carbonization: Step (2) The density of the carbon / carbon heating element product is ≥0.80g / cm 3 At this time, carry out pressure impregnation treatment with furfurone resin, immerse in the impregnation tank for 5 hours under the pressure of 2.0MPa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Needling density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com