Preparation method of transition metal sulfide catalytic material and catalytic application thereof

A technology of transition metals and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as low degree of sulfidation, low experimental repeatability, and inability to be widely used to achieve weakening The effects of strong interaction, good experimental repeatability, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

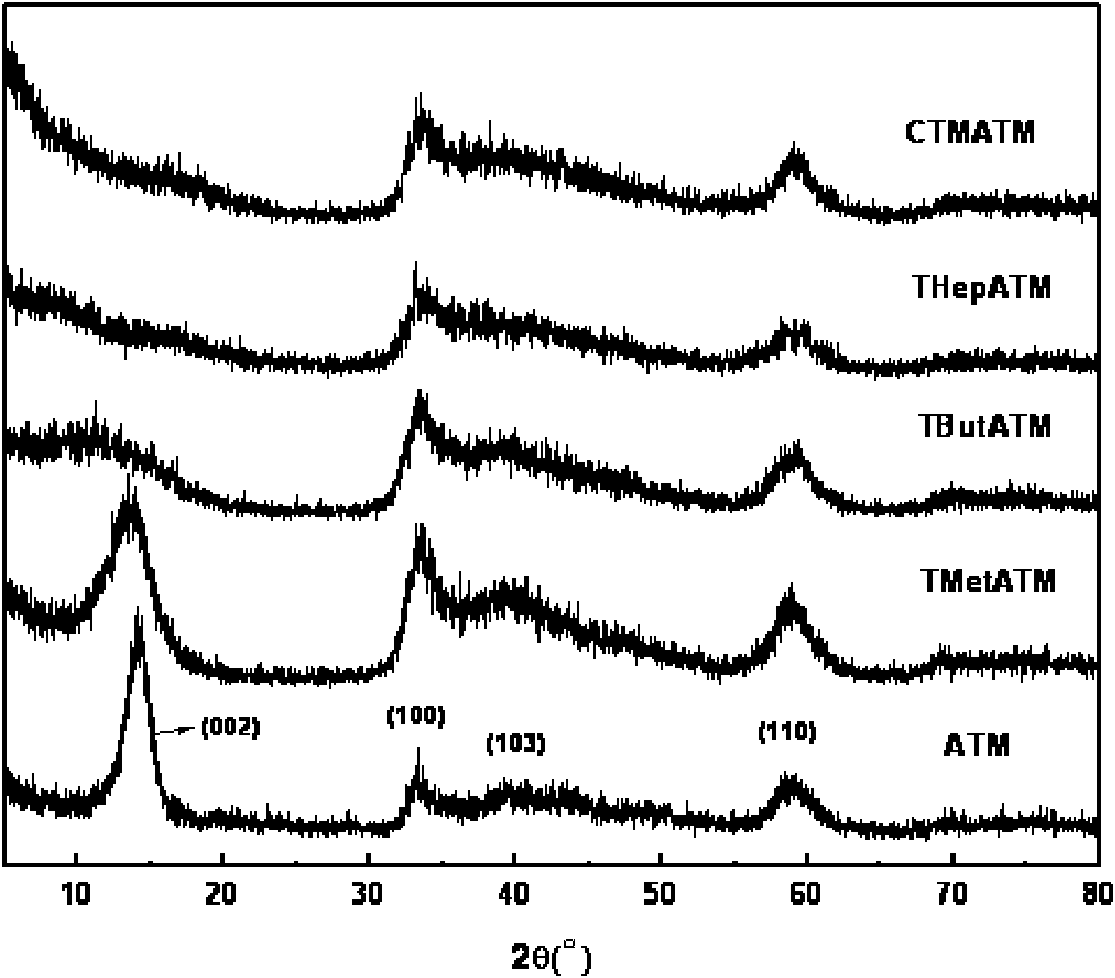

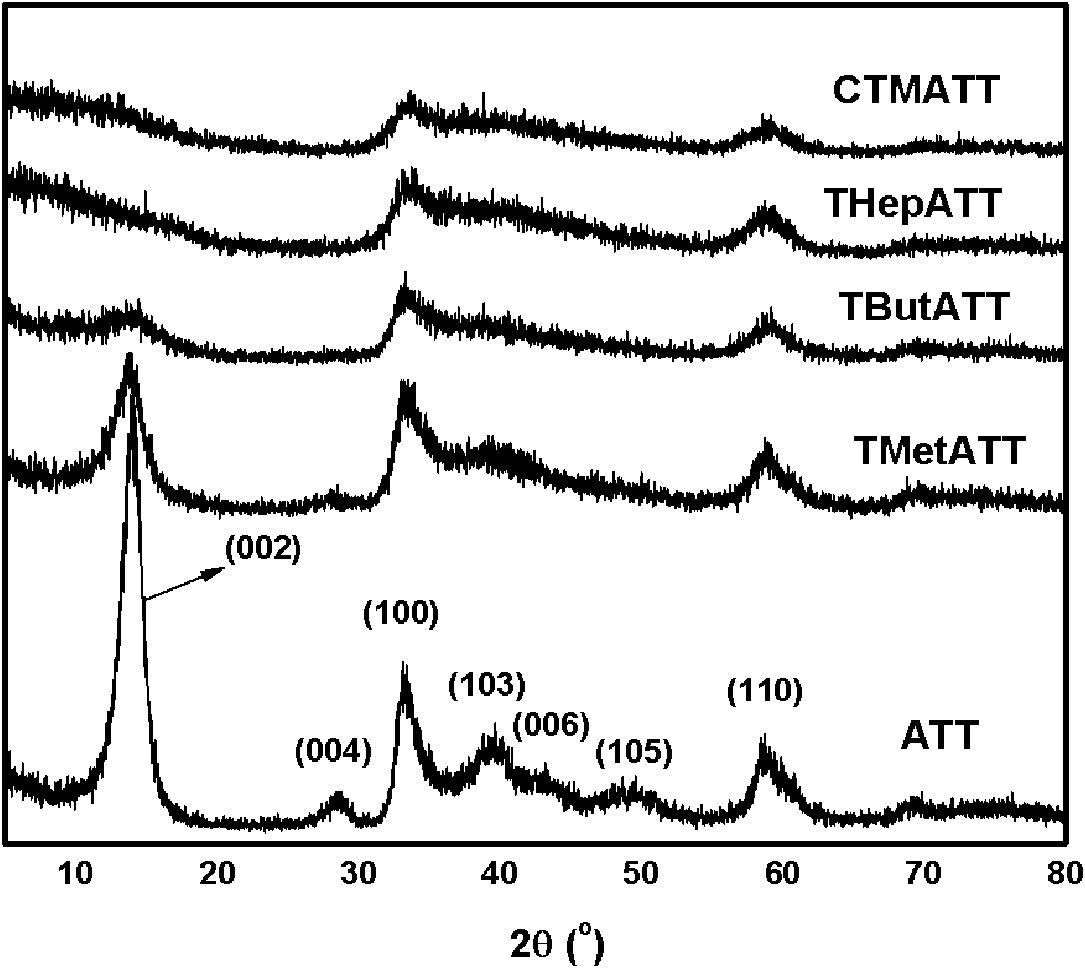

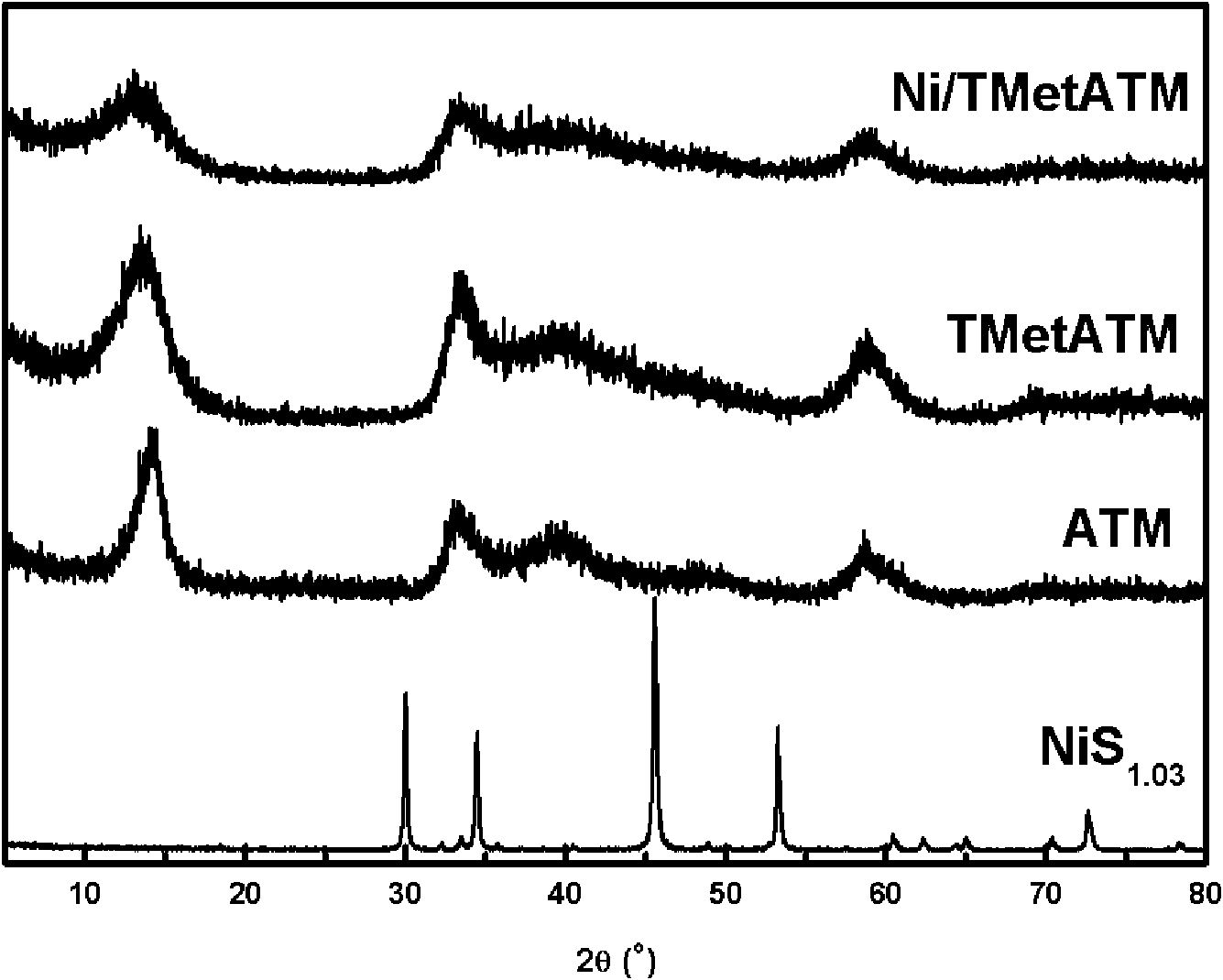

Embodiment 1

[0022] Weigh 0.5000g of ammonium tetrathiomolybdate and dissolve it in 15mL of water, dissolve 0.4200g of tetramethylammonium chloride and 0.1491g of sodium hydroxide in 10mL of water together, and add the solution of ammonium tetrathiomolybdate to tetramethyl chloride In the solution of ammonium chloride and sodium hydroxide, stir for a few minutes, add a large amount of absolute ethanol to produce a large amount of orange flocculent precipitate, and filter to obtain an orange needle-like crystal substance. Under an inert atmosphere, the temperature is programmed to be pyrolyzed, and the pyrolysis temperature range is 100-600°C to obtain a molybdenum disulfide solid catalyst, which is identified as molybdenum disulfide by X-ray powder. The specific surface area of the sample is 108m 2 / g.

Embodiment 2

[0024] Dissolve 0.5000g of ammonium tetrathiomolybdate in 15mL of water, dissolve 1.4000g of cetyltrimethylammonium bromide and 0.1491g of sodium hydroxide in 30mL of water, mix the two, let stand overnight, and filter to obtain light orange Crystal powder. Under an inert atmosphere, the temperature is programmed to be pyrolyzed, and the pyrolysis temperature range is 100-600°C to obtain a molybdenum disulfide solid catalyst, which is identified as molybdenum disulfide by X-ray powder. The specific surface area of the sample is 190m 2 / g.

Embodiment 3

[0026] Dissolve 0.5000g of ammonium tetrathiotungstate in 20mL of water, dissolve 1.0891g of cetyltrimethylammonium bromide and 0.1120g of sodium hydroxide in 20mL of water, mix the two to produce a yellow flocculent precipitate, and let it stand for a while In the evening, it was filtered to obtain a yellow crystalline powder. Under an inert atmosphere, the temperature is programmed to be pyrolyzed, and the pyrolysis temperature range is 100-600°C to obtain a tungsten disulfide solid catalyst, which is identified as tungsten disulfide by X-ray powder. The specific surface area of the sample is 150m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com