Method for preparing giant magnetoresistance films by vacuum vapor deposition method

A giant magneto-impedance, vacuum coating machine technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve weak adhesion between layers, difficulty in achieving anisotropy, poor compactness and uniformity and other problems, to achieve the effect of uniform film, low preparation cost and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

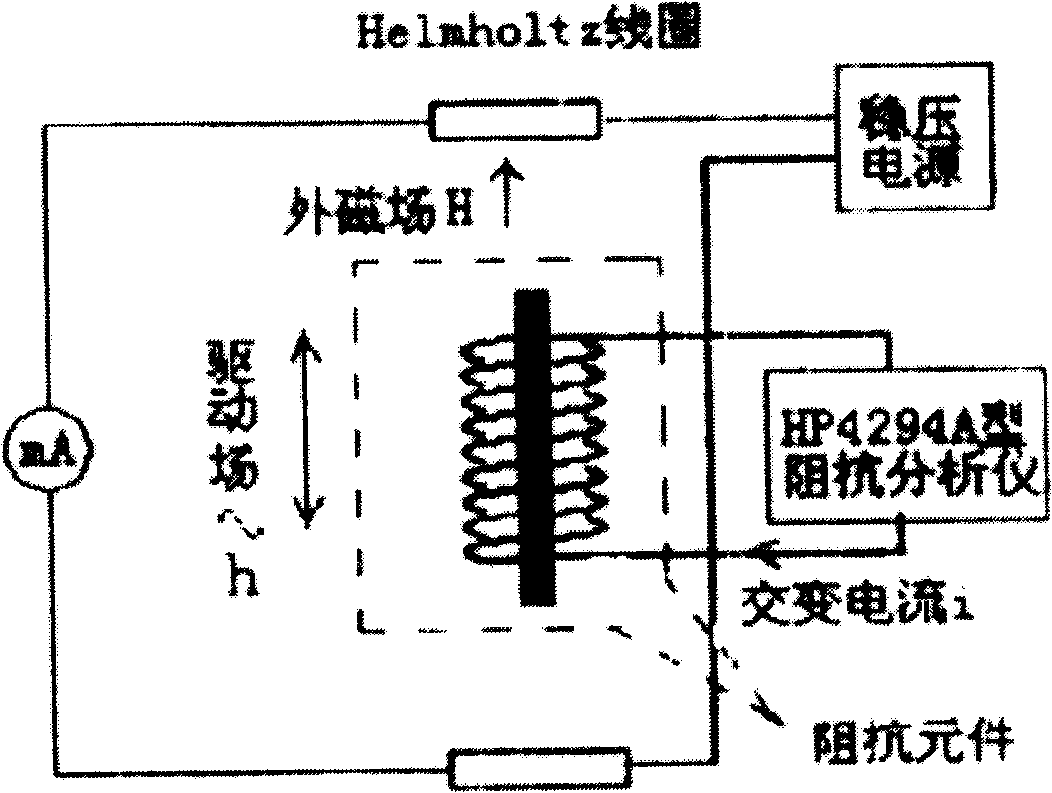

[0024] The method for preparing the giant magnetoresistance thin film material by the vacuum evaporation method of the present invention is when preparing the FeSiB monolayer thin film, what we adopt is the DMDE-450 type coating machine, with magnetic deflection 270 ° electron gun and film thickness controller, can vapor deposition Various high and low melting point metals and oxide materials. SiO 2 The substrate is cleaned in the following steps: (1) the substrate is polished with polishing powder, and the polishing powder for polishing the substrate is preferably rare earth polishing powder. It is recommended to use cerium oxide polishing powder, which has fine particle size, strong grinding force, fast polishing speed, good brightness and easy cleaning. The reason why cerium oxide is an extremely effective polishing compound is that it can simultaneously polish the substrate in two forms of chemical decomposition and mechanical friction; (2) the substrate is placed in a qu...

Embodiment 2

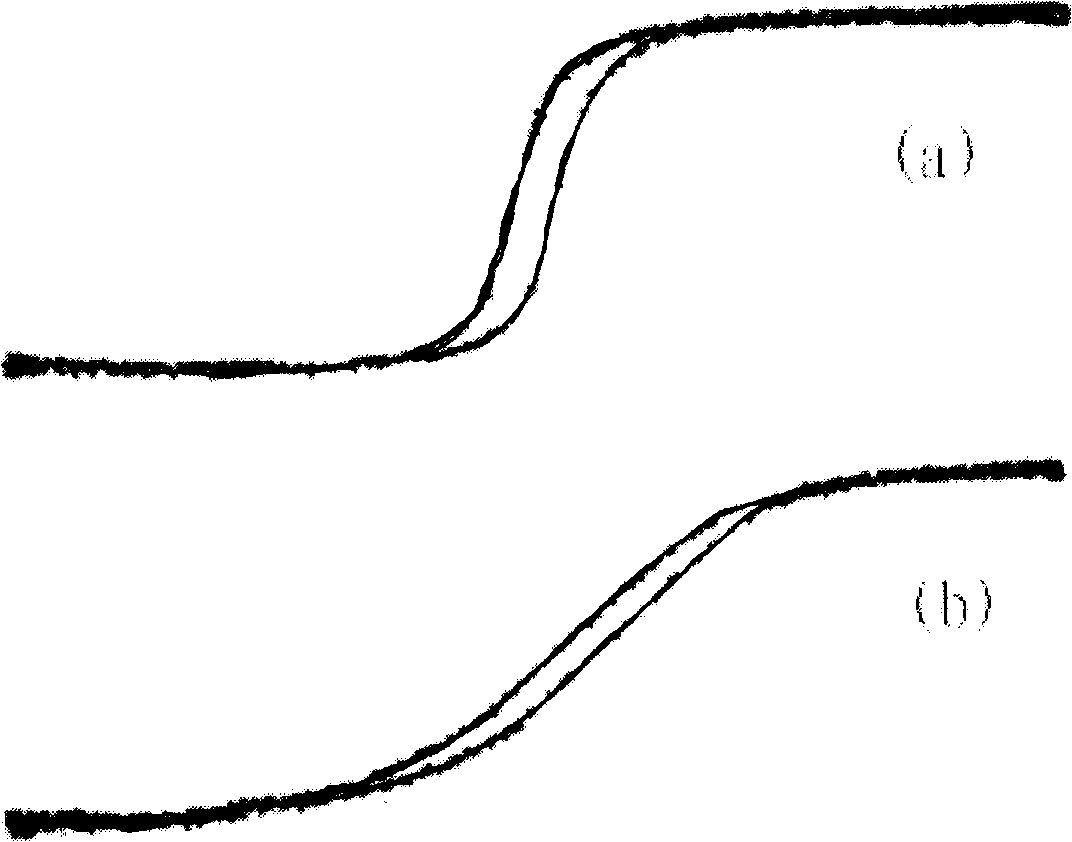

[0032] The method for preparing the giant magnetoresistance thin film material by the vacuum evaporation method of the present invention also adopts a DMDE-450 type coating machine with a magnetic deflection 270° electron gun and a film thickness controller when preparing the FeSiB / Cu / FeSiB multilayer film. , can evaporate various high and low melting point metals and oxide materials. SiO 2 The substrate cleaning is also the same, also at 10 -4 ~10 -3 Pa low pressure environment. A method of keeping the glass substrate in a stable magnetic field is also adopted. Specifically, permanent magnets are added on both sides of the glass substrate to provide a stable magnetic field of 0.2T, so that the glass substrate is always under the action of this stable magnetic field during the entire coating process. The atomic ratio of the FeSiB thin film material is 77.5:7.5:15 , the material has been alloyed in this proportion in advance. When the vacuum degree of the vacuum chamber re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com