Method for preparing anatase-shaped nano TiO2

An anatase-type, nano-titanium dioxide technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of particle agglomeration and achieve the effect that it is not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

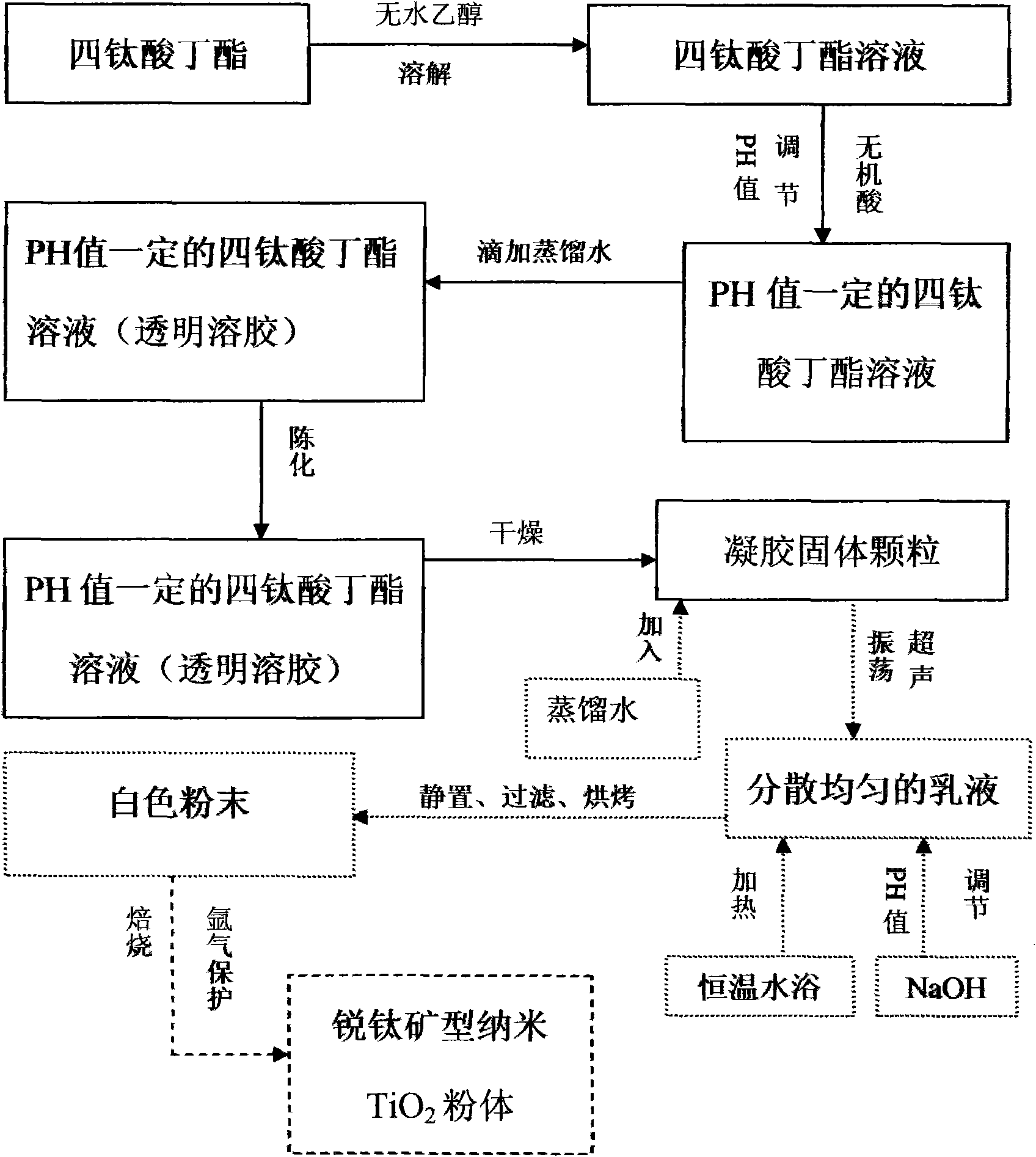

Method used

Image

Examples

Embodiment 1

[0031] Tetra-n-butyl titanate Ti(OC 4 h 9 )4 as TiO 2 The precursor of absolute ethanol (C 2 h 5 OH) as an organic solvent, by changing the preparation conditions to prepare suspension-type TiO 2 nanocatalyst materials. 50g Ti(OC 4 h 9 ) 4 Dissolved in 25g of absolute ethanol to obtain uniformly mixed Ti(OC 4 h 9 ) 4 / ethanol solution, and adjust the pH value to about 5.5 with hydrochloric acid solution, then slowly add 5g of distilled water, and continuously stir for 4 hours to obtain a transparent sol, which becomes a transparent solid after aging for 24 hours, and dried in an oven at 125°C for 6 hours to become a white solid particle ;Pour the powder into a crucible, pass argon gas for 5 minutes to reach saturation, put the crucible in a muffle furnace, turn on the heating, and roast at 500°C for 1 hour to obtain TiO 2 powder. The obtained TiO 2 It is a small white particle with high hardness and is difficult to grind. Its particle size is relatively large and ...

Embodiment 2

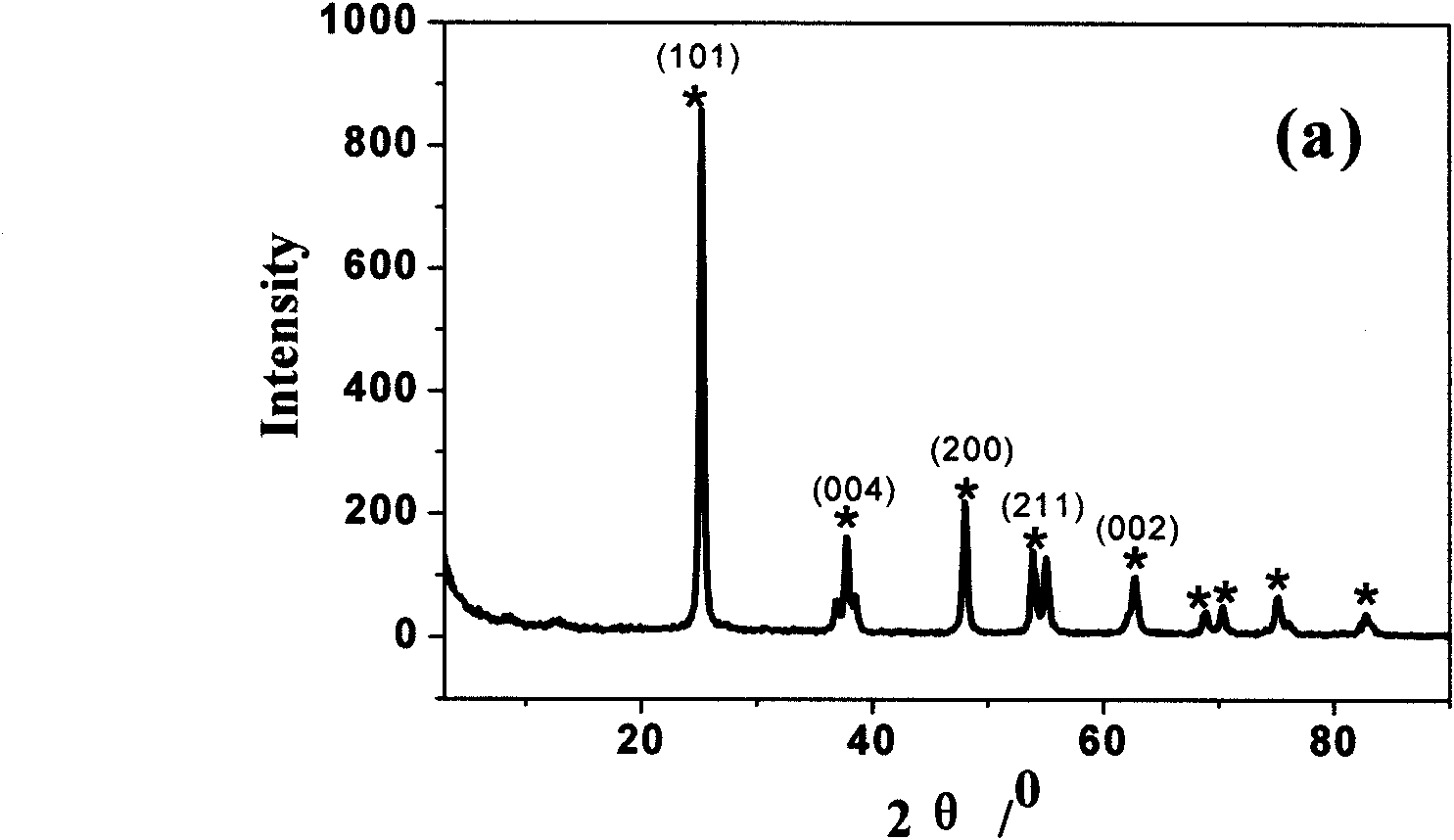

[0033] 50g Ti(OC 4 h 9 ) 4 Proportionally dissolved in 250g of absolute ethanol to obtain uniformly mixed Ti(OC 4 h 9 ) 4 / ethanol solution, and adjust the pH value to about 5.5 with hydrochloric acid solution, then slowly add 5g of distilled water, and continuously stir for 4 hours to obtain a transparent sol, which becomes a transparent solid after aging for 24 hours, and dried in an oven at 125°C for 6 hours to become a white solid particle ;Transfer the granules to a beaker, add 150g of water, ultrasonically oscillate for 30min, let stand for 2h, filter to remove most of the water, and then put it in an oven again to dry at 125°C for 3h to obtain a crisp and self-colored solid; pour the powder into a crucible In the process, the crucible was placed in the muffle furnace after being saturated with argon for 5 minutes, the heating was turned on, and the TiO was obtained by roasting at 500°C for 1 hour. 2 powder. The TiO obtained in this way 2 The photocatalytic materi...

Embodiment 3

[0035] 20g Ti(OC 4 h 9 ) 4 Proportionally dissolved in 20g of absolute ethanol to obtain uniformly mixed Ti(OC 4 h 9 ) 4 / anhydrous ethanol solution, and adjust the pH value to about 5.5 with hydrochloric acid solution, then slowly add 2g of distilled water, and continuously stir for 4 hours to obtain a transparent sol. White solid particles; transfer the particles to a beaker, add 20g of water, oscillate ultrasonically for 30 minutes, let it stand still, filter to remove most of the water, and then put it in an oven to dry at 100°C for 3 hours to obtain a white powder; pour the powder into a crucible In the process, the crucible was placed in the muffle furnace after being saturated with argon for 5 minutes, the heating was turned on, and the TiO was obtained by roasting at 500°C for 1 hour. 2 powder. The results of various physical characterizations show that the physical properties of nano-titanium dioxide prepared by this method are consistent with those in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com