Microwave plasma resonant cavity used for depositing diamond film

A microwave plasma, diamond thin film technology, applied in the field of resonant cavity, can solve the problems of large volume, unfavorable system cooling, large sub-field intensity area, etc., and achieves a reduced system volume, high cavity Q value and high concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

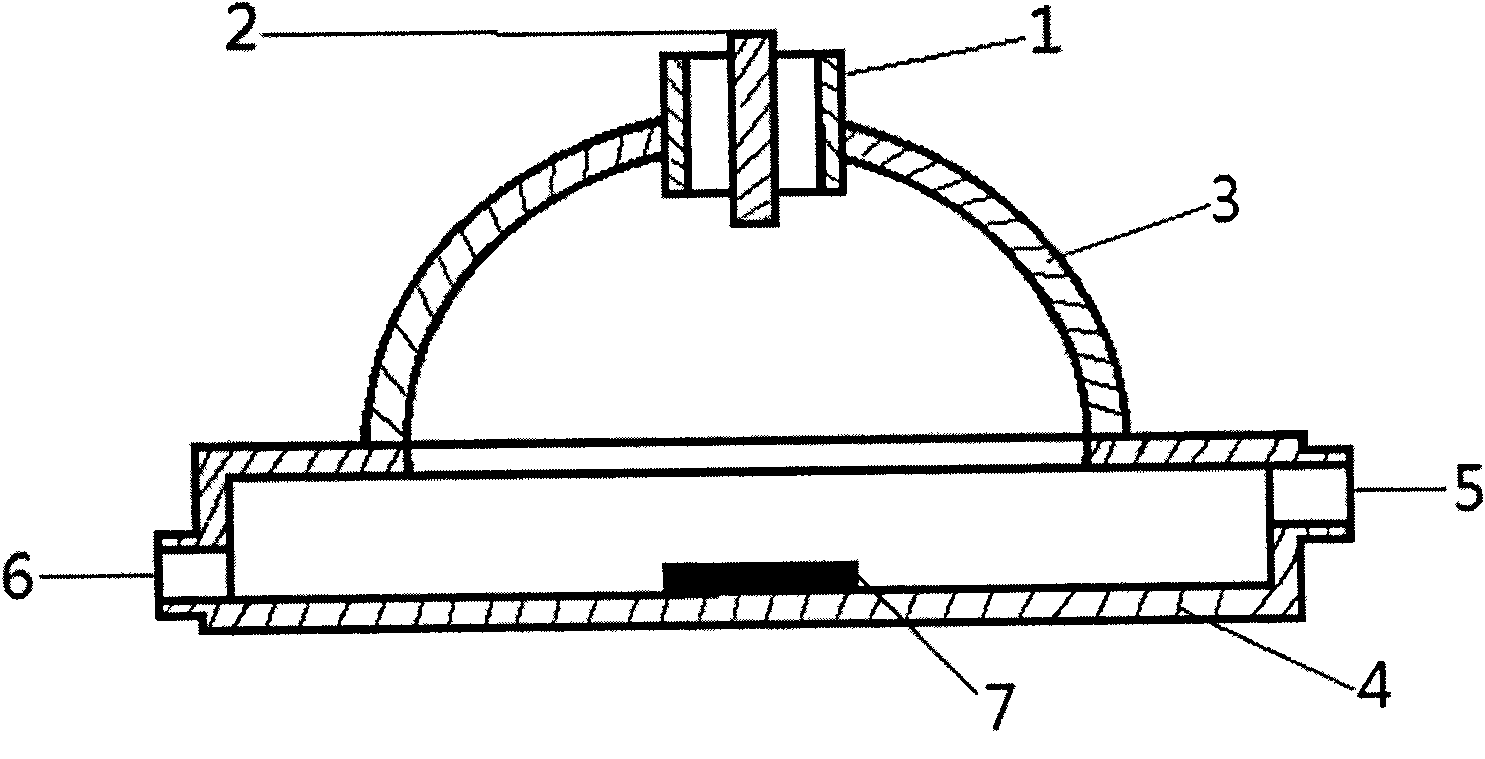

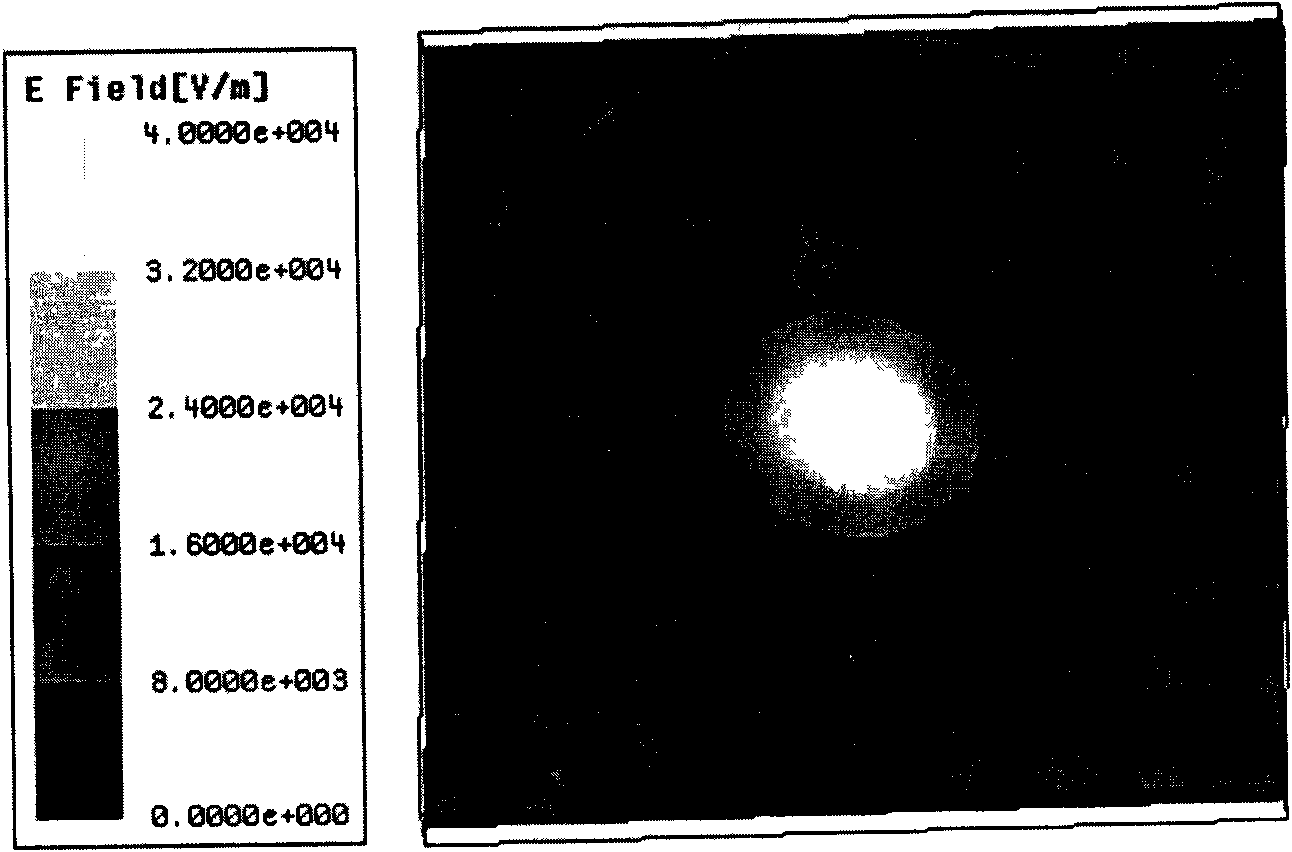

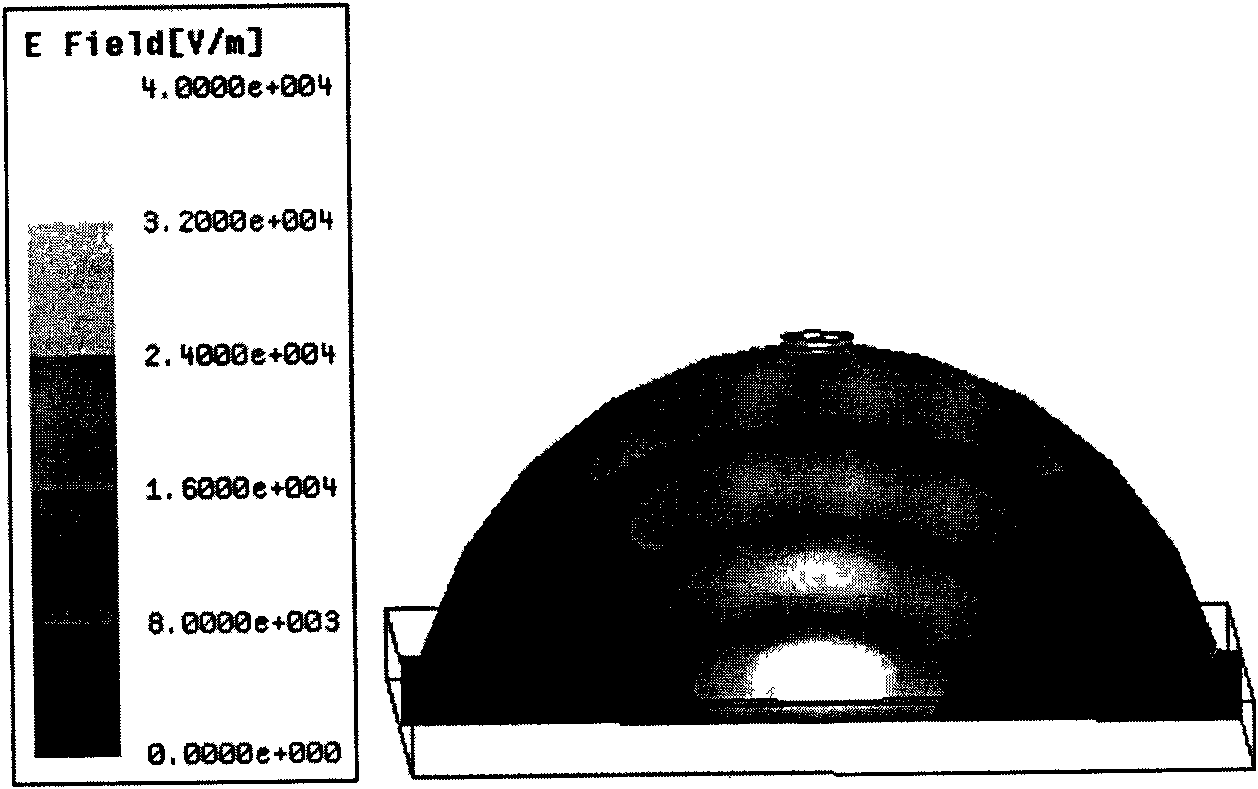

[0012] The microwave plasma resonant cavity of this embodiment: the inner diameter of the cylindrical waveguide input tube 1 is Ф50mm, the axial height is 20mm, the tube wall thickness is 2mm, and the material is stainless steel; The height of the bottom surface of the chamber 4 is 251.7mm, and the material is copper; the radius of curvature of the hemispherical metal chamber 3 is R295.6mm (R=2.42λ), and the height of the inner chamber (from the top of the hemispherical inner chamber to the outer top surface of the box-shaped metal chamber 4 distance) 221.7mm, the inner diameter of the lower port is Ф572.42mm, the thickness is 2mm, and the material is stainless steel; the box-shaped metal cavity 4. This embodiment adopts a square metal cavity with a side length of 300mm and an inner cavity height of 50mm. The diameter of the central hole on the top of the box body is the same as The diameter of the lower port of the hemispherical metal chamber 3 is the same as Ф572.42mm, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com