Preparation method of aluminum alloy corrosion resistant coating

A corrosion-resistant coating, aluminum alloy technology, applied in the direction of metal material coating process, coating, device for coating liquid on the surface, etc. Corrosion resistance is unstable and other problems, to achieve the effect of high economic return, flexible construction, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

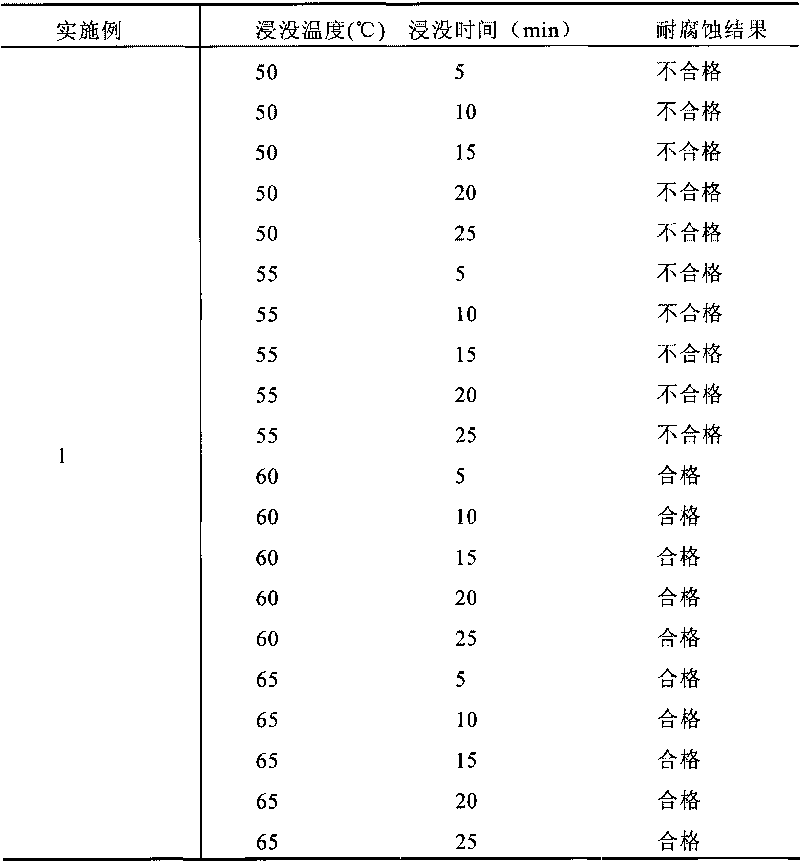

Embodiment 1

[0025] Add 18.8L pure water (or deionized water) to the 25L stainless steel bucket, and then add 1.375Kg ammonium nitrate (NH 4 NO 3 ), 0.65Kg cobalt nitrate (Co(NO 3 ) 2 .6H 2 O), 0.66L formic acid (HCOOH), 0.3mol / L ammonium hydroxide (NH 4 OH) aqueous solution directly mixed solution PH=6.8-7.2, then add 0.325Kg sodium nitrite (NaNO 2 ), 5mL of 30wt% hydrogen peroxide (H 2 O 2 ) aqueous solution, heated to 55-65°C under normal nitrogen jet stirring for 30-90 minutes. After the reaction, 0.3 mol / L ammonium hydroxide (NH 4 OH) aqueous solution until the PH of the reaction solution = 6.8-7.2, set aside.

[0026] The clean aluminum alloy test plate is heated and soaked in an aqueous solution of cobalt at 50-65°C for 5-25 minutes, then taken out and dried at room temperature for 24 hours, and then the surface of the test plate is treated with a spray solution of oxidized polyaniline doped mercapto organic acid compound , vacuum drying to remove excess solvent, salt spray...

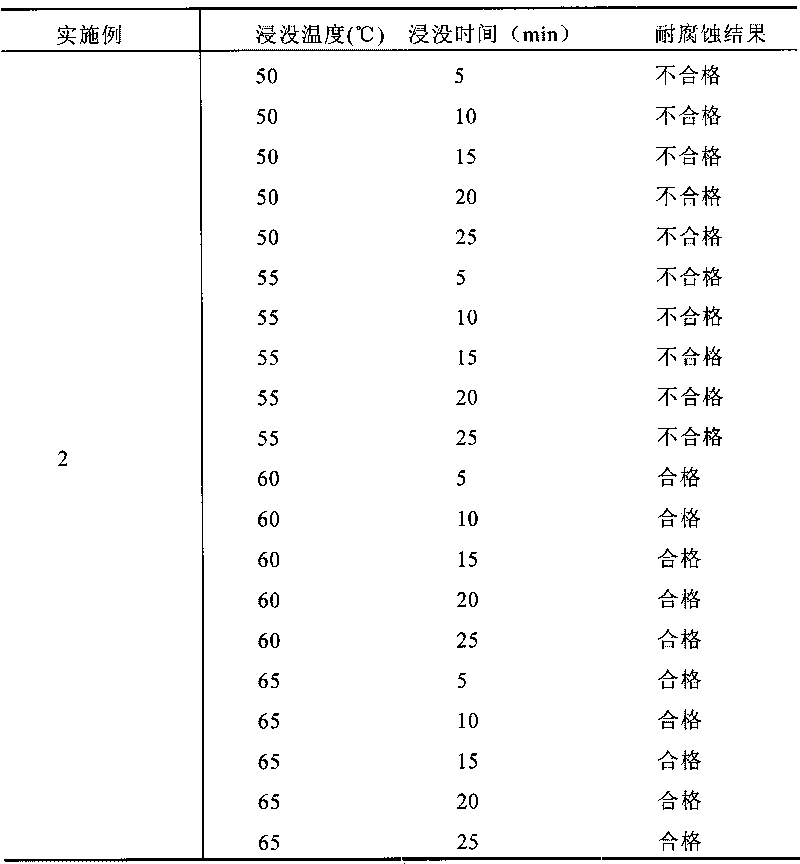

Embodiment 2

[0028] Add 16.7L pure water (or deionized water) to the 25L stainless steel bucket, and then add 1.325Kg ammonium nitrate (NH 4 NO 3 ), 0.65Kg cobalt nitrate (Co(NO 3 ) 2 .6H 2 O), 1L glacial acetic acid (CH 3 COOH), 20 mL of 30 wt% hydrogen peroxide (H 2 O 2 ) aqueous solution, activated ordinary nitrogen jet stirring device, and reacted for 10 to 15 minutes. Add 0.325Kg of sodium nitrite (NaNO 2 ) heated to 36-42°C for 20-30 minutes. Then 0.42mol / L ammonium hydroxide (NH 4 OH) aqueous solution until the pH of the reaction solution = 6.7-7.0, and finally add 5 mL of 30 wt% hydrogen peroxide (H 2 O 2 ) aqueous solution, heated to 55-65°C, stirred for several minutes, and set aside.

[0029] The clean aluminum alloy test plate is heated and soaked in an aqueous solution of cobalt at 50-65°C for 5-25 minutes, then taken out and dried at room temperature for 24 hours, and then the surface of the test plate is treated with a spray solution of oxidized polyaniline doped ...

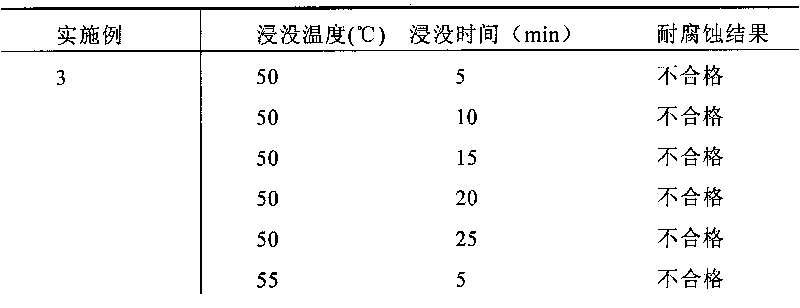

Embodiment 3

[0031] Add 18.8L of pure water (or deionized water) to the 25L stainless steel bucket under ordinary nitrogen jet stirring, and then add 1.375Kg of ammonium nitrate (NH 4 NO 3 ), 0.65Kg cobalt nitrate (Co(NO 3 ) 2 .6H 2 O), 0.66L ammonium formate (NH 4 COOH), dropwise add 0.2mol / L ammonium hydroxide (NH 4 OH) aqueous solution directly mixed solution PH=7.0-7.1, then add 0.325Kg sodium nitrite (NaNO 2 ), 5mL of 30wt% hydrogen peroxide (H 2 O 2 ) aqueous solution reaction, slight ammonia gas was generated in the process, and the reaction continued for 5-10 minutes. Then the temperature was further raised to 55-65°C for 30-90 minutes. After the reaction, 0.2mol / L ammonium hydroxide (NH 4 OH) aqueous solution until the PH of the reaction solution = 7.0-7.1, set aside.

[0032] The clean aluminum alloy test plate is heated and soaked in an aqueous solution of cobalt at 50-65°C for 5-25 minutes, then taken out and dried at room temperature for 24 hours, and then the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com