Bacillus subtilis and pyrimethanil compounded bactericide and application thereof

A technology of Bacillus subtilis and compound fungicides, applied in the directions of fungicides, applications, biocides, etc., can solve the problems of excessive pesticide residues, pollute the ecological environment of orchards, and affect the quality of fruit products, achieve fast bacteriostatic speed, and improve prevention and control. Effect, control effect Stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

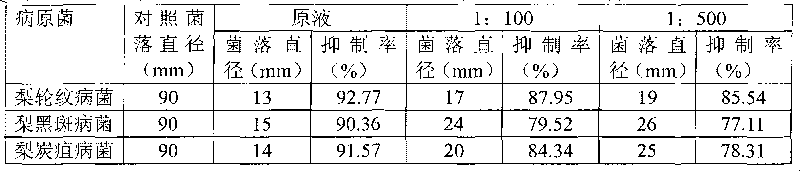

[0020] Inhibitory effect of Bacillus subtilis sf-628 on mycelial growth of R. pear ringworm, black spot and anthracnose fungus.

[0021] The tested fungal pathogen strains: Pear ringworm, black spot fungus, and anthracnose bacteria were provided by the Plant Protection Institute of Jiangsu Academy of Agricultural Sciences. The tested pathogenic bacteria were transplanted on PSA medium (200g potato, 20g sucrose, 20g agar and 1000ml distilled water, pH5.6~6.6), cultured in 28℃ incubator for 5d, and set aside.

[0022] Activate the biocontrol bacteria sf-628 on the NA slope (3g beef extract, 1g yeast extract, 5g peptone, 10g sucrose, 20g agar and 1000ml distilled water, pH6.8~7.0), and then transfer to 50ml NA culture medium medium, shake (150r / m) at 28°C for 48h, and set aside. Place the mycelium block of pathogenic bacteria in the center of the PSA plate, with a diameter of 7mm; place 4 filter paper sheets diagonally around the petri dish (the distance from the center of the p...

Embodiment 2

[0026] Preparation of 13% pyrimethanil · 10 billion Bacillus subtilis wettable powder.

[0027] Drugs for testing:

[0028] 40% pyrimethanil EC was produced by Jiangsu Nanjing Gesell Chemical Industry Co., Ltd.

[0029] The 60 billion Bacillus subtilis wettable powder is produced and provided by Jiangsu Suke Agrochemical Co., Ltd.

[0030] Additive: NNO (sodium methylene dinaphthalene sulfonate).

[0031] Filling accessories: light calcium carbonate

[0032] Each component is prepared according to weight percentage:

[0033] 40% pyrimethanil EC: 32.5%; 60 billion Bacillus subtilis wettable powder: 16.7%; additive NNO: 8%; light calcium carbonate: 42.8%.

[0034] Preparation process: put pyrimethanil and Bacillus subtilis in the mixer according to the above ratio, add NNO (sodium methylene dinaphthalene sulfonate), fill it with light calcium carbonate to 100%, and mix all materials in the mixer After uniformity, it is pulverized twice by a jet mill to obtain 13% pyrimethanil...

Embodiment 3

[0036] Preparation of 10% pyrimethanil · 10 billion Bacillus subtilis suspension.

[0037] The sources of 40% pyrimethanil EC and 60 billion Bacillus subtilis wettable powder are the same as in Example 2.

[0038] Auxiliary selection: sodium lignosulfonate, OP-10; CMC; organosilicone; ethylene glycol.

[0039] Solvent of choice: water.

[0040] Each component is prepared according to weight percentage:

[0041] 40% pyrimethanil EC: 25%; 60 billion Bacillus subtilis wettable powder: 16.7%; sodium lignosulfonate: 9%; OP-10: 4%; thickener CMC: 1%; defoamer organic Silicone: 0.01%; antifreeze glycol: 5%; water: appropriate amount.

[0042] Preparation process: put pyrimethanil, Bacillus subtilis, sodium lignosulfonate, OP-10, thickener CMC, defoamer organic silicone, antifreeze ethylene glycol in the reaction kettle according to the above ratio, add water Mix evenly until 100%, and then introduce the mixture into a sand mill to grind until the material fineness is 1-5 μm; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com