Compound copper conductor with decoration and antiseptic effect and manufacturing method thereof

A technology of anti-corrosion effect and production method, which is applied in the cross field of material surface science and physical chemistry, can solve the problems of poor decoration and poor wear resistance, and achieve the effects of good formability, enhanced corrosion resistance and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

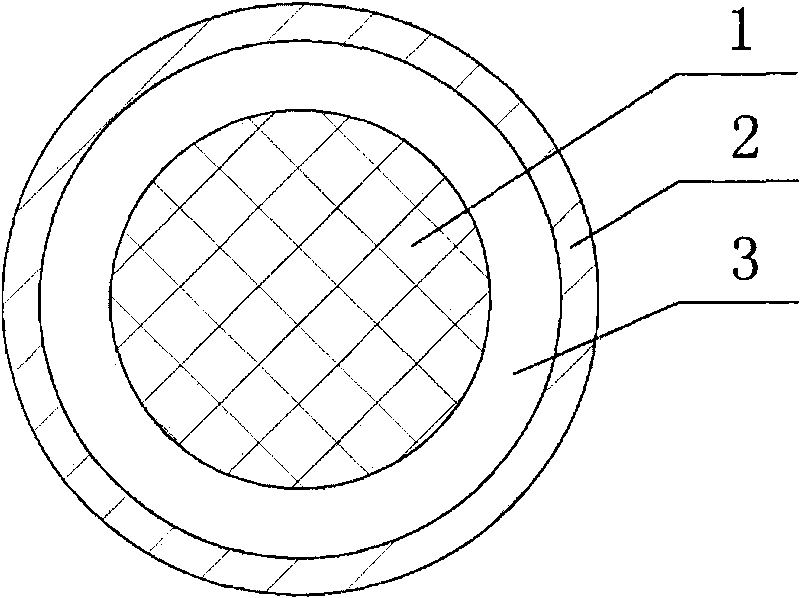

[0046] Φ11 round copper rod formed by dipping and galvanizing figure 1 Composite conductor:

[0047] 1) Use a plate of Φ11 circular copper rod as the copper substrate 1, and manually polish the surface of the copper substrate 1;

[0048] 2) Roll the polished Φ11 round copper rod into a mosquito-repellent coil disc or an equal-diameter spring-type disc, and use a certain number of hanging rods to hang all of them firmly to ensure that they will not disperse when subjected to a certain impact force. Opening and deformation, when hanging, it is required that the copper rods of each circle do not overlap, and an appropriate interval is left between the copper rods of each circle. Clean the suspended workpiece with flowing water to remove the residue left during polishing;

[0049] 3) Carry out alkali washing and degreasing again, immerse the workpiece in the alkaline degreasing solution for degreasing, the temperature of the alkaline degreasing solution is 80° C., and the alkali...

Embodiment 2

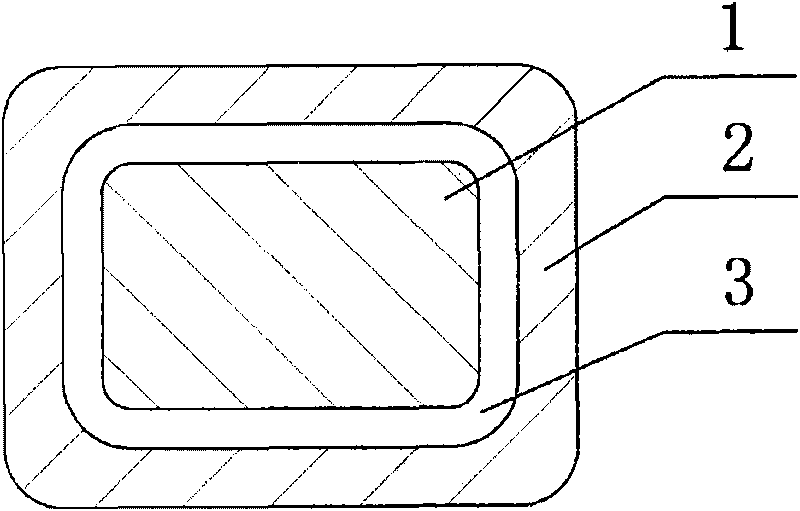

[0064] Made of disc-shaped 4×25 flat copper strips such as figure 2 Composite conductor shown:

[0065] 1) Use about 50KG of 4×25 flat copper strip rolled into a spring-shaped disc as the copper substrate 1, and manually polish and polish the surface of the copper substrate 1;

[0066] 2) Hang the polished spring disc-shaped 4×25 flat copper substrate 1 on the hanger hanger, and hang all the copper strips firmly, and when subjected to a certain impact force, they will not scatter and deform. When hanging, it is required that the copper strips of each circle cannot overlap, and an appropriate distance should be left between each other. Clean the suspended workpiece with running water to remove the residue left during polishing;

[0067] 3) Carry out alkali washing and degreasing again, immerse the workpiece in an alkaline degreasing solution for degreasing, the temperature of the alkaline degreasing solution is 60°C, and the alkali washing and degreasing time is 20 minutes; ...

Embodiment 3

[0087] Composite conductor made of 4×40 straight flat copper bars:

[0088] 1) Mechanically grinding and polishing the surface of the conductor copper substrate 1 with 15 straight strips of 4×40 flat copper strips;

[0089] 2) Hang and firmly hang 15 straight 4×40 flat copper strips with a hanger, and clean them with running water after polishing to remove the residue left during polishing;

[0090] 3) Carry out alkali washing and degreasing again, immerse the workpiece in an alkaline degreasing solution for degreasing, the temperature of the alkaline degreasing solution is 70°C, and the alkali washing and degreasing time is 18 minutes; / l, Na 3 PO 4 22g / l, Na 2 CO 3 38g / l, water glass 4g / l, OP-10 emulsifier 2g / l;

[0091] 4) After degreasing, wash with hot water at 60°C for 1.5 minutes; then wash with deionized water at room temperature for 1.2 minutes;

[0092] 5) Pickling to remove the oxide skin, put the workpiece after thorough degreasing and cleaning into the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com