Method for preparing positive plate for electrolyzing manganese dioxide

A technology for electrolyzing manganese dioxide and anode plates, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of large-scale anode plates, limited application scope, unstable electrical contact, etc. Reduce production costs and achieve the effect of semi-continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

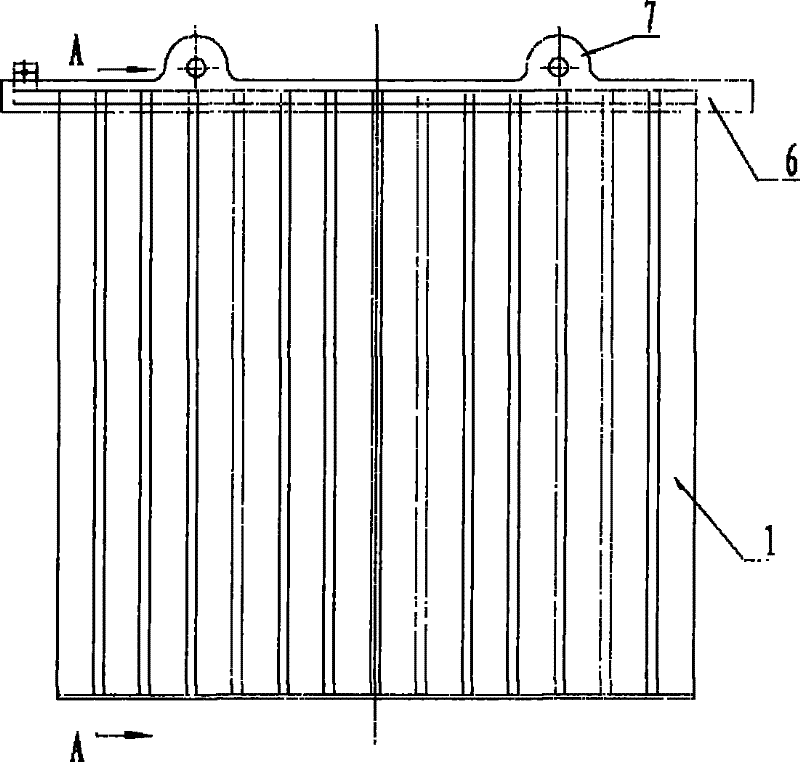

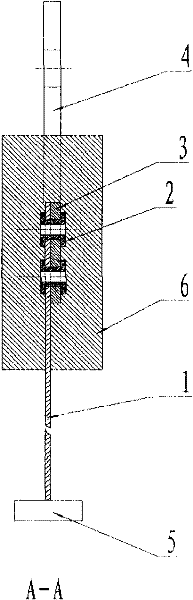

Embodiment 1

[0026] The metal powder components are titanium and manganese, and the weight percentages of each component are as follows: titanium: 50%, manganese: 50%. Polyvinyl alcohol and water are prepared into an aqueous solution of a binder at a mass ratio of 1:100, and then metal powder is added to an aqueous solution of a binder 5 times the weight of the metal powder, stirred evenly, and then coated with a spray gun and pressed into an NW combination Type 1350mm×84mm×1.5mm pure titanium plate surface, leave 10mm at the lower end without coating, place it in a vacuum storage tank at room temperature after drying, and evacuate to 10 -5 Pa was filled with argon gas protection, and then the titanium plate coated with metal powder was continuously pulled to be heated by a constant temperature vacuum heating furnace located directly above the vacuum storage tank. When pulling, the effective heating time of each part of the workpiece is guaranteed to be 10 minutes. After heating, it is qui...

Embodiment 2

[0030] Other process conditions are the same as in Example 1, the constant temperature is 1300° C., and the determination of the pulling speed: ensure that the effective heating time of each part of the workpiece is 15 minutes. Under normal industrial electrolysis conditions, the current density is 100A / m 2 , the tank voltage is stable between 2.5 and 2.8 volts; the electrolytic manganese dioxide product has a good appearance.

Embodiment 3

[0032] Other process conditions are the same as in Example 1, the constant temperature is 1200° C., and the determination of the pulling speed: ensure that the effective heating time of each part of the workpiece is 30 minutes. Under normal industrial electrolysis conditions, the current density is 100A / m 2 , the tank voltage is stable between 2.6 and 2.9 volts; the appearance of the electrolytic manganese dioxide product is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com