Method for jointly stabilizing fly ash and arsenic-containing waste

A fly ash and waste technology, applied in the field of hazardous waste stabilization treatment, can solve the problems of high cost and large capacity increase ratio, and achieve the effects of reducing environmental risks, saving storage capacity and having strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The objects of treatment are arsenic-containing tailings slag from a chemical plant and fly ash from a flue gas purification system of a municipal solid waste incineration plant. The arsenic slag is in the form of yellow mud. Its water content, pH, and redox potential were tested, and its main element composition, mineral composition, and heavy metal leaching toxicity were analyzed. The results are as follows: the moisture content of the arsenic slag is 81.4%, the pH is 1.53, and the redox potential is -84mV , X-ray diffractometer (XRD) detects arsenic mainly as As 2 o 3 The main components of arsenic slag are As, S, and Cd as measured by X-ray fluorescence spectrometer (XRF). The toxic leaching method of solid waste leaching in my country——acetic acid buffer solution method (HJ / T 300-2007) leaching, inductive coupling Plasma emission spectrometer (ICP) measures metal ion concentration, obtains the leaching concentration of As 1501.5mg / L, the leaching concentration of C...

Embodiment 2

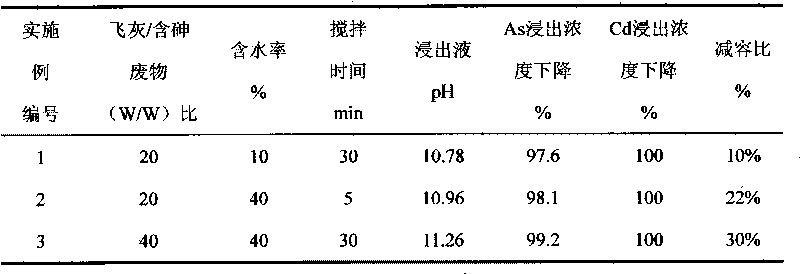

[0021] The properties and proportions of fly ash and arsenic slag are the same as in Example 1. Add the regulating solution, control the mass ratio of the regulating solution to the mixed solid of fly ash and arsenic slag to be 4:6, and mechanically stir for 5 minutes at room temperature until uniform. The leaching concentration of heavy metals such as Pb, Se, Cd, Ni in the mixture measured by the same method as in Example 1 is lower than the national hazardous waste identification standard, the heavy metal pollution of the fly ash itself is controlled, and the As leaching concentration in the arsenic slag is reduced simultaneously To 28.3mg / L, compared with untreated leaching concentration decreased by 98.1%. In addition, the leaching concentration of other metal ions did not exceed the standard. The results show that fly ash and arsenic slag can achieve co-stabilization. The specific stabilization results are shown in Table 1.

Embodiment 3

[0023] The properties of fly ash and arsenic slag are the same as in Example 1. According to the ratio of 1 kg of arsenic slag to 40 kg of fly ash, add the adjustment liquid to the tank reactor, control the mass ratio of the adjustment liquid to the mixed solid of fly ash and arsenic slag to 4:6, and mechanically stir at room temperature for 30 minutes until uniform . Measure the heavy metal leaching concentration such as Pb, Se, Cd, Ni in the mixture with the same method as embodiment 1 and be all lower than national hazardous waste identification standard, the heavy metal pollution of fly ash itself is controlled, and the As leaching concentration in the arsenic slag is reduced to 12.2mg / L, the leaching concentration decreased by 99.2% compared with untreated. In addition, the leaching concentration of other metal ions did not exceed the standard. The results show that fly ash and arsenic slag can achieve co-stabilization. The specific stabilization results are shown in T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com