Catalyst for oxidation sweetening of diesel oil and application thereof

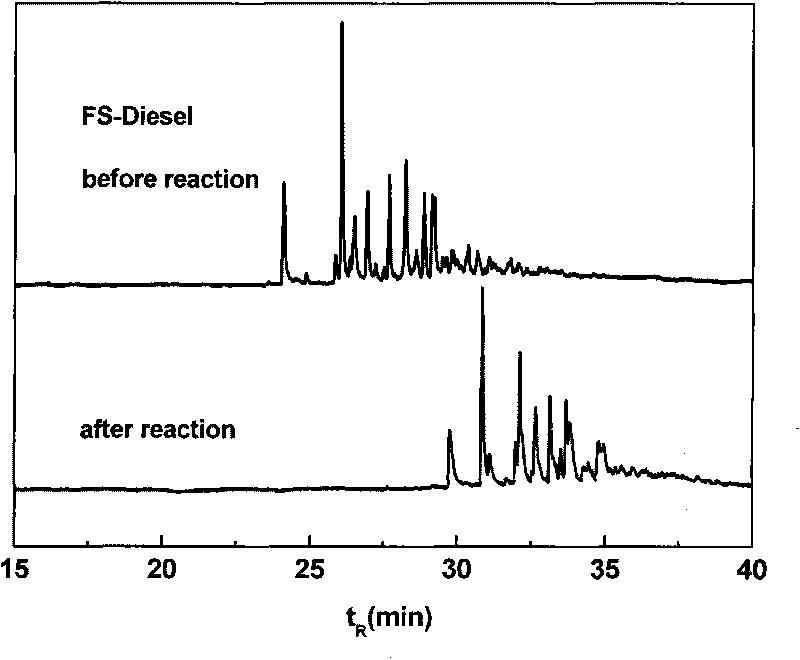

An oxidative desulfurization and catalyst technology, which is applied in the direction of physical/chemical process catalysts, refining with oxygen-containing compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the difficulty of removing thiophene sulfide, chlorinated hydrocarbon High toxicity, unfriendly environment and other problems, to prevent the effect of affecting the quality of oil products, reduce production costs, and easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of catalyst in the present invention.

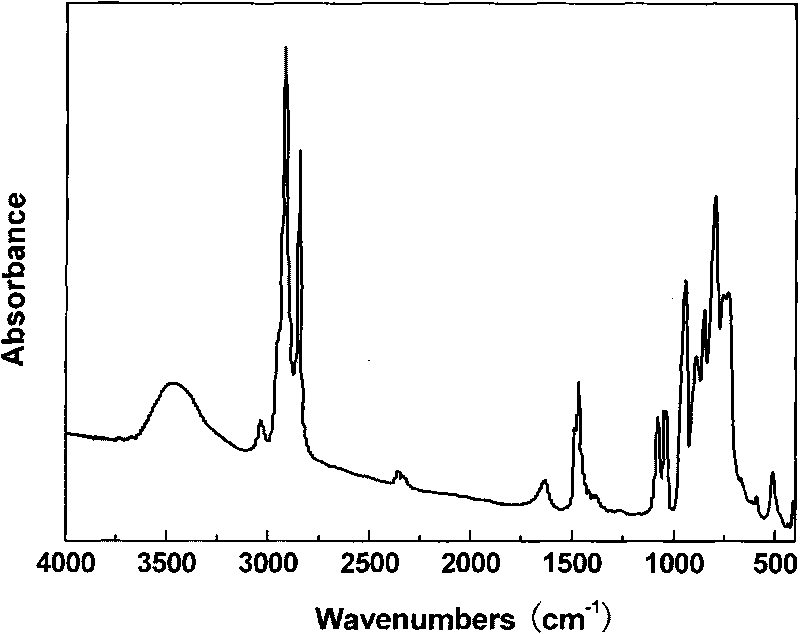

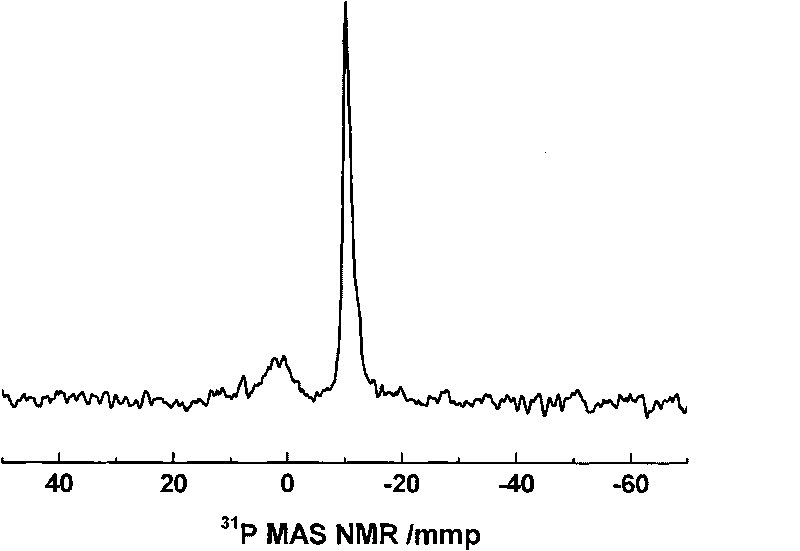

[0030] Dissolve 10g of ammonium metatungstate and 1.0g of sodium phosphate in 80ml of water, stir vigorously in a water bath at 25°C for 30min; add 40ml of 1M HNO 3 , stirred for 30min; weighed 2.6g of octadecyltrimethylammonium chloride and dissolved it in 10ml of water, dropped it into the above mixed solution in a water bath at 80°C, and stirred vigorously at the same time, a white precipitate was formed immediately, and the dropping time was 1h. Stirring was continued for 3 hours; finally, it was filtered, washed with deionized water, and dried in vacuo to obtain a white solid catalyst. Called catalyst A, the molecular formula is [C 18 h 37 N(CH 3 ) 3 ] 4 h 2 Na[PW 10 o 36 ], its IR and NMR characterizations are shown in the attached figure 1 with 2 .

Embodiment 2

[0032] Use octyl trimethyl quaternary ammonium salt 1.6g to be dissolved in 5ml water, all the other operation steps are with embodiment 1, are called catalyst B, through infrared and NMR characterization, its molecular formula is [C 8 h 17 N(CH 3 ) 3 ] 4 HNa 2 [PW 10 o 36 ].

Embodiment 3

[0034] Use dodecyl trimethyl quaternary ammonium salt 2.0g to be dissolved in 5ml water, all the other operation steps are with embodiment 1, are called catalyst C, through infrared and NMR characterization, its molecular formula is [C 12 h 25 N(CH 3 ) 3 ] 4 h 3 [PW 10 o 36 ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com