Carbon-carbon composite guide cylinder of CZ silicon crystal growing furnace and preparation method thereof

A technology of carbon composite materials and guide tubes, which is applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of affecting service life, increased consumption of guide tube materials, frequent replacement, etc., and achieve good heat preservation Excellent performance and thermal shock resistance, reduced consumption of raw materials, and remarkable effects of energy saving and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment.

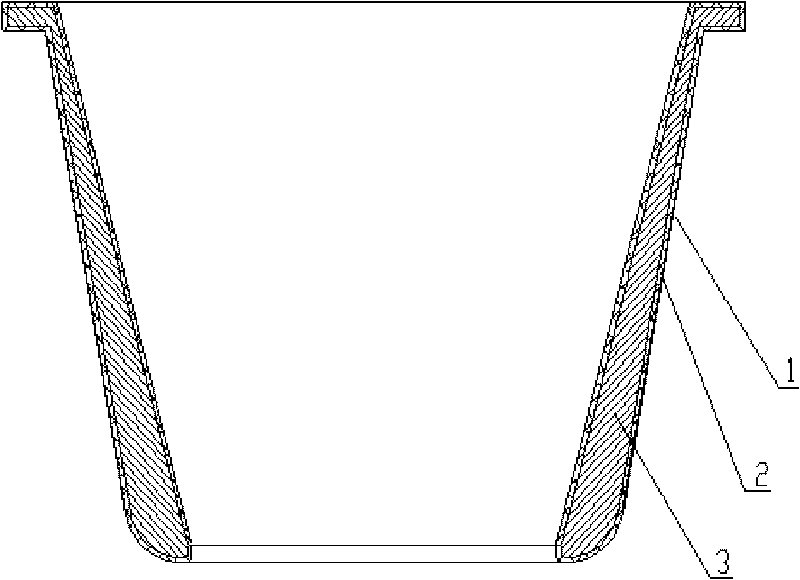

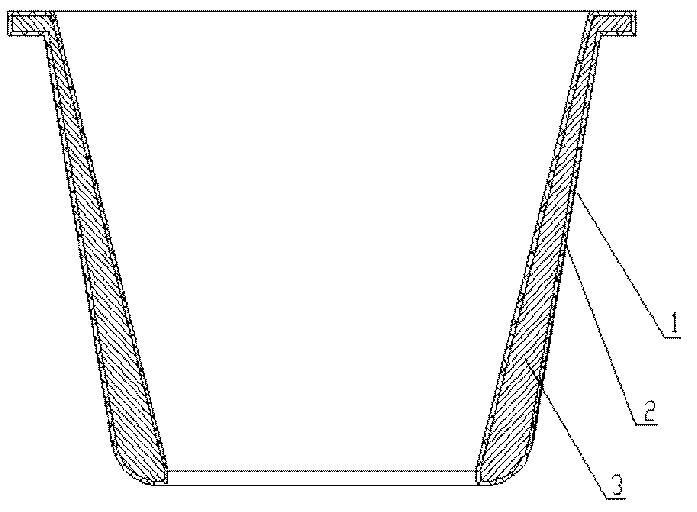

[0025] Referring to Fig. 1, the embodiment of the carbon-carbon composite guide cylinder of the present invention is composed of a surface silicon carbide coating 1, a carbon-carbon composite material surface layer 2 and a carbon-carbon composite material central layer 3; the carbon-carbon composite material surface layer The apparent density is 1.5g / cm 3 ; The apparent density of the carbon-carbon composite center layer is 0.4g / cm 3 .

[0026] Taking the operation steps of making a carbon-carbon composite guide tube with an inner diameter of Φ260mm at one end, an inner diameter of the other end of Φ452mm, and a height of 370mm as an example, the preparation method of the carbon-carbon composite guide tube of the present invention will be further described in detail:

[0027] (1) Make a top diameter Φ260mm, a bottom diameter Φ452mm, and a frustum-shaped graphite mold with a height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com