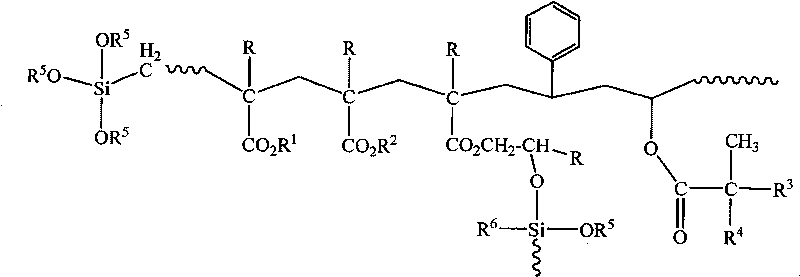

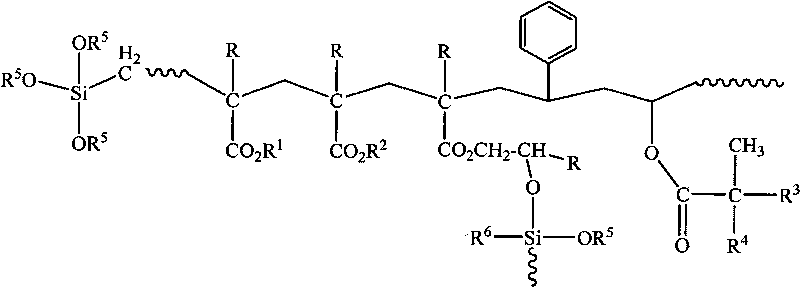

Self-drying low aliphatic chain oxosilane modified water-borne acrylic resin and preparation method thereof

A water-based acrylic and chain siloxane technology, used in coatings, latex paints, anti-corrosion coatings, etc., can solve the problems of low aging resistance, poor emulsion stability, complex process flow, etc., and achieve low cost, molecular weight and other problems. The effect of easy control and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

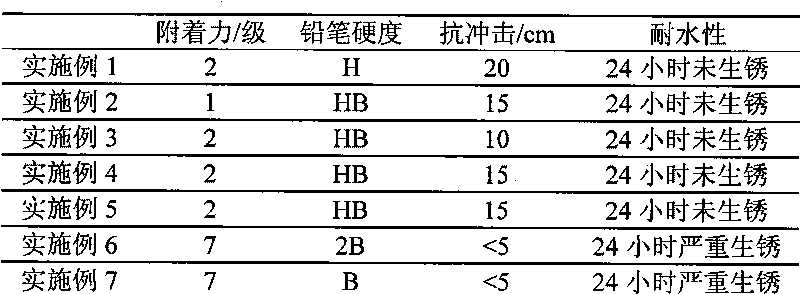

Examples

Embodiment 1

[0041] 75 g of ethylene glycol butyl ether was added to the four-necked flask, and the temperature was raised to 90°C. then drop

[0042] Methyl methacrylate 50g,

[0043] Butyl methacrylate 10g,

[0044] Methacrylic acid 10g,

[0045] Acrylate-beta-hydroxypropyl ester 4g,

[0046] Styrene 8g,

[0047] Vinyl tertiary carbonate 4g,

[0048] Dodecylmercaptan 1g,

[0049] Benzoyl peroxide 1.5g,

[0050] Trimethoxyethylsilane 15g,

[0051] The temperature was raised to 100°C, and the dropwise addition was completed in 2 and a half hours. React at 110°C for 1 hour, cool to below 50°C, and adjust the pH value to 8-9 with triethylamine. Add 25 g of water for dispersion to obtain a light yellow water-dispersed silicone-modified acrylic resin with a solid content of 50%.

Embodiment 2

[0053] Use n-butanol and ethylene glycol butyl ether at a ratio of 1:1 as solvent, and heat up to 90°C. then drop

[0054] Methyl methacrylate 55g,

[0055] Butyl methacrylate 15g,

[0056] Methacrylic acid 10g,

[0057] Acrylate-beta-hydroxypropyl ester 4g,

[0058] Styrene 8g,

[0059] Vinyl tertiary carbonate 4g,

[0060] Dodecylmercaptan 1g,

[0061] Benzoyl peroxide 1.5g,

[0062] Trimethylolsilane 12g,

[0063] The temperature was raised to 100°C, and the dropwise addition was completed in 2 and a half hours. React at 110°C for 1 hour, cool to below 50°C, and adjust the pH value to 8-9 with triethylamine. 25 g of water was added for dispersion to obtain a water-dispersed silicone-modified acrylic resin with a solid content of 54%.

Embodiment 3

[0065] Ethylene glycol monoethyl ether was used as a solvent, and the temperature was raised to 90°C. then drop

[0066] Methyl methacrylate 60g,

[0067] Methyl acrylate 5g,

[0068] Butyl acrylate 15g,

[0069] Acrylic acid 7g,

[0070] 2 g of β-hydroxyethyl acrylate,

[0071] Styrene 2g,

[0072] Vinyl tertiary carbonate 2g,

[0073] Benzoyl peroxide 3g,

[0074] Dodecylmercaptan 3g,

[0075] Trimethylolsilane 10g,

[0076] The temperature was raised to 100°C, and the dropwise addition was completed in 2 and a half hours. React at 110°C for 1 hour, cool to below 50°C, and adjust the pH value to 8-9 with ammonia water. 25 g of water was added for dispersion to obtain a water-dispersed silicone-modified acrylic resin with a solid content of 54%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com