Compound oxygen reduction electro-catalyst of carbon nano materials modified by macrocyclic compound containing nitrogen and preparation method thereof

A technology of macrocyclic compounds and carbon nanomaterials, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of weak interaction between modified molecules and carrier materials , poor stability and anti-poisoning ability, low catalytic activity, etc., to achieve the effect of low preparation cost, good oxygen reduction catalytic activity, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

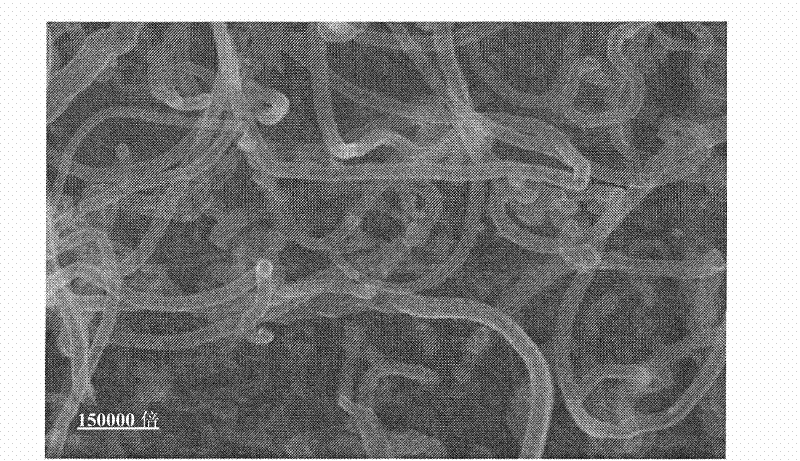

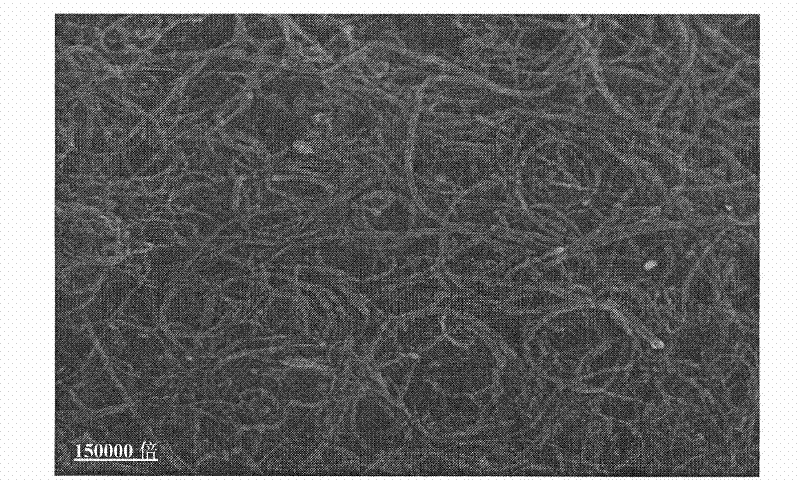

[0039] Dissolve 0.1mg of nickel phthalocyanine in 10ml of N,N-dimethylformamide, then add 1mg of carbon nanotubes, shake well, 60KHz ultrasonic compound for 24 hours, filter under reduced pressure and wash the filtrate with deionized water until it is colorless, The filter cake was dried at 80° C. for 12 hours, and cooled to obtain a composite oxygen reduction electrocatalyst of nickel phthalocyanine-modified carbon nanotubes. figure 1 is the scanning electron microscope image of blank carbon nanotubes, figure 2 It is a scanning electron micrograph of carbon nanotubes modified with nickel phthalocyanine. from figure 2 It can be clearly seen that nickel phthalocyanine can be well adsorbed on the surface of carbon nanotubes to form a composite oxygen reduction electrocatalyst of nickel phthalocyanine modified carbon nanotubes.

Embodiment 2

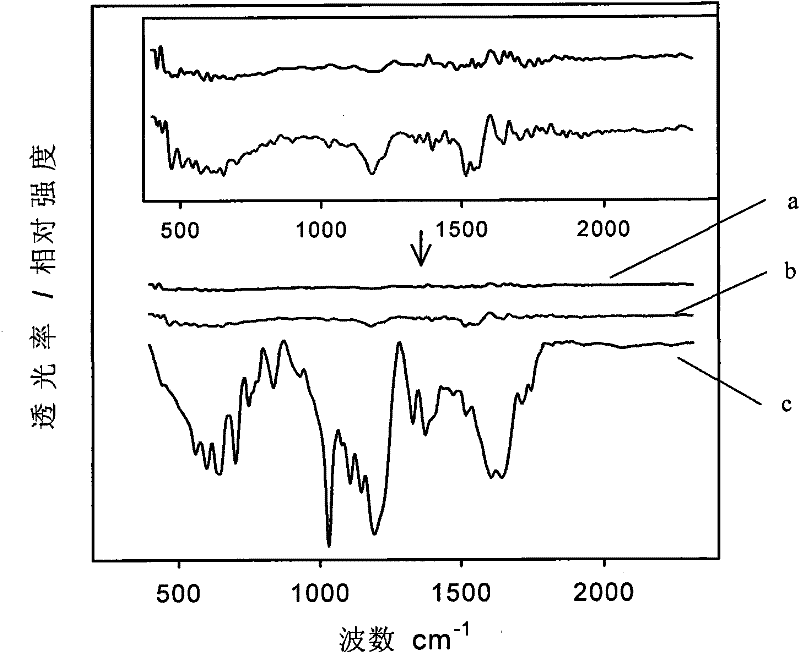

[0041] Dissolve 0.2mg of copper phthalocyanine in 40ml of chloroform, then add 4mg of carbon nanoparticles, shake well, 60KHz ultrasonic compound for 24 hours, filter under reduced pressure and wash the filtrate with deionized water until it is colorless, and dry the filter cake at 80°C for 12 hours, cooling to obtain a composite oxygen reduction catalyst of copper phthalocyanine modified carbon nanoparticles. image 3 It is the Fourier transform infrared spectrogram of copper phthalocyanine (line c in the figure), carbon nanoparticles (line a in the figure) and the composite catalyst of copper phthalocyanine modified carbon nanoparticles (line b in the figure). It can be seen from the figure that the blank carbon nanotube (line a in the figure) basically has no absorption peak. When copper phthalocyanine is modified on carbon nanoparticles to form a complex, the characteristic absorption peak of copper phthalocyanine obviously appears on the composite oxygen reduction catalys...

Embodiment 3

[0043] Dissolve 0.2mg of iron phthalocyanine in 20ml of water, then add 4mg of carbon nanotubes, shake well, 50KHz ultrasonic compound for 18 hours, filter under reduced pressure and wash the filtrate with deionized water until it is colorless, and dry the filter cake at 80°C for 12 hours , cooling to obtain a composite oxygen reduction catalyst. Disperse 2mg of the prepared composite oxygen reduction electrocatalyst in 1ml of 0.1% Nafion solution to obtain 2mg.mL -1 oxygen reduction electrocatalyst solution. 5 μL of the solution was dropped onto the surface of a glassy carbon electrode (3 mm in diameter), and the electrode was dried at room temperature to obtain a modified electrode containing a composite oxygen reduction electrocatalyst. With the modified electrode as the working electrode, an electrochemical workstation (Shanghai Chenhua Electrochemical Instrument Co., Ltd., CHI660C) and a standard three-electrode system (platinum wire as the auxiliary electrode, and an Ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com