Polyurethane elastomer with lateral chain containing fluoroalkyl and preparation method thereof

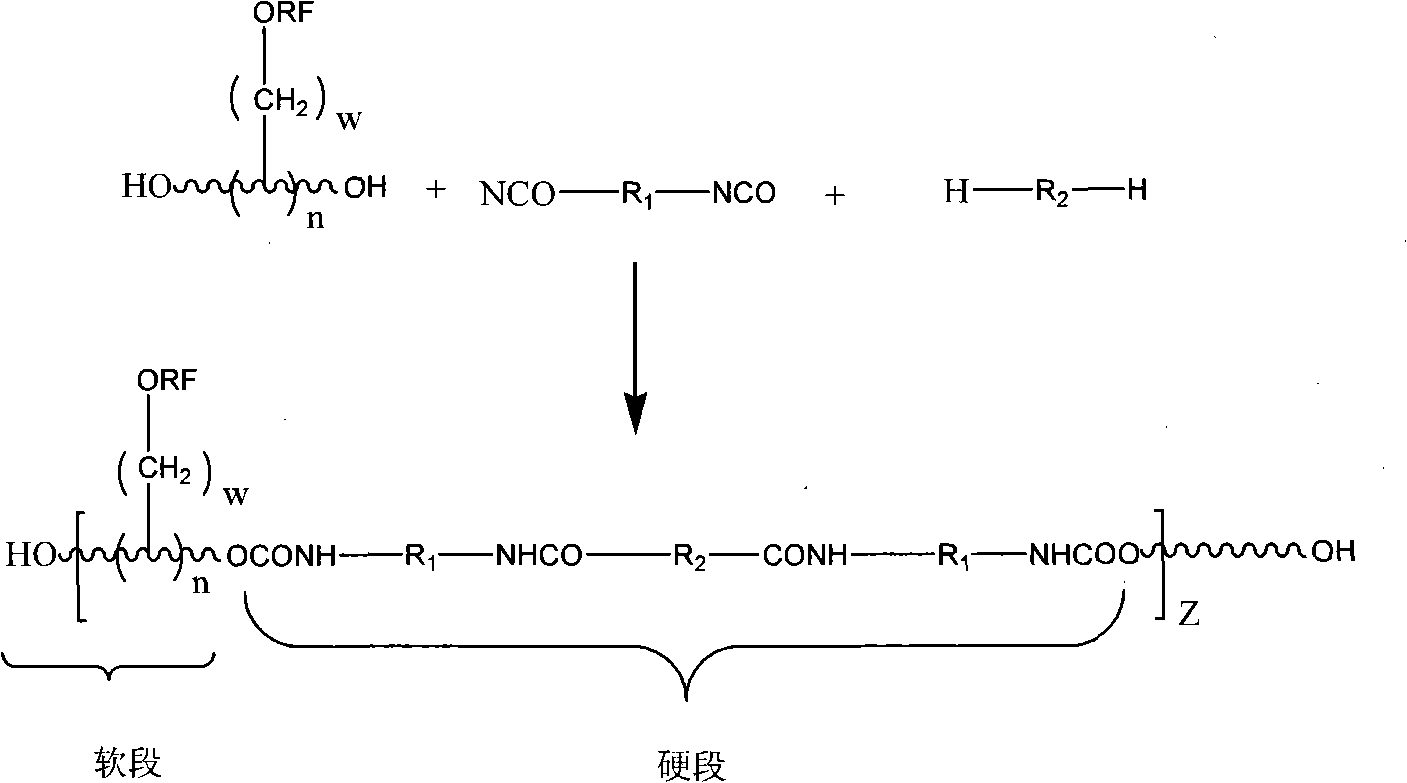

A polyurethane elastomer, fluorine-containing alkyl technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of short molecular chain length of side chain fluorine group, limited industrial application, non-adjustment, etc., to achieve excellent resistance. The effect of chemical corrosion, excellent mechanical properties, extremely low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

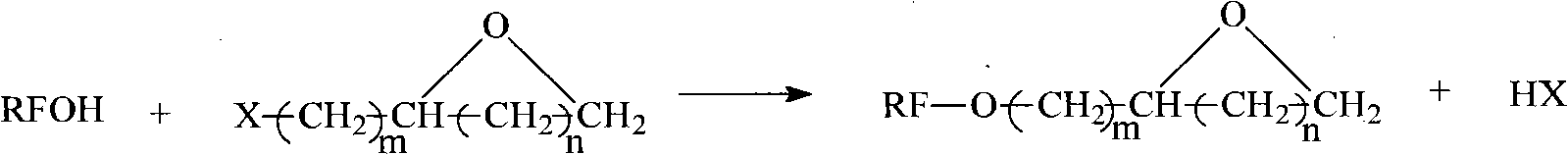

[0050] (1) Add tetrafluoropropanol, epichlorohydrin and sodium hydroxide sequentially according to the molar ratio of 1:1:10, then add 50mL of 1,4-dioxane to it, stir under nitrogen protection, and The reaction was carried out at constant temperature at 50°C for 3h. After the reaction was over, the solution was poured off. Distill under reduced pressure at a vacuum degree of 1 mmHg to obtain a fluoroalkyl-substituted propylene oxide compound monomer.

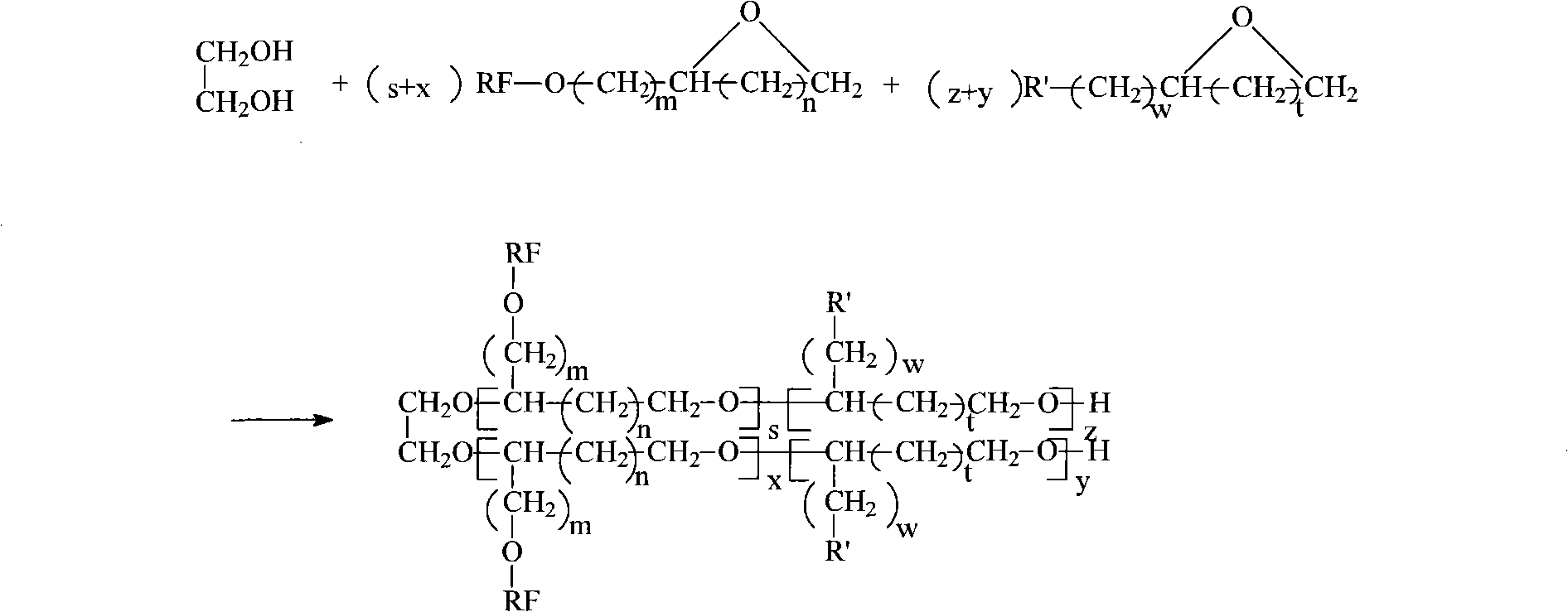

[0051] (2) Add tetrahydrofuran, ethylene glycol, and boron trifluoride ether into the flask in sequence according to the molar ratio of 1:0.1:0.001, and then add 100 mL of dichloromethane into it, and stir. Then, 0.4 mol of the fluoroalkyl-substituted propylene oxide compound obtained in step (1) was added dropwise thereto, and reacted at 20° C. for 3 h. After the reaction is over, add water equivalent to 50 times the volume of the raw material for washing. After static separation, the oil phase was distilled under reduced pr...

Embodiment 2

[0055] In step (3), change 2mol of diphenylmethane diisocyanate into 4mol of 1,6-hexamethylene diisocyanate (HDI), change 30mL of acetone into 300mL of ethyl acetate, and other steps are the same as in Example 1.

[0056] The contact angle of the polyurethane elastomer containing fluoroalkyl groups in the side chain to water is 63°, the tensile strength is 16.5MPa, and the glass transition temperature is 167°C.

Embodiment 3

[0058] In step (3), change 2mol of diphenylmethane diisocyanate into 6mol of toluene diisocyanate, change 30mL of acetone into 20mL of butanone, and other steps are the same as in Example 1.

[0059] The contact angle of the polyurethane elastomer containing fluoroalkyl groups in the side chain to water is 65°, the tensile strength is 15.5MPa, and the glass transition temperature is 157°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com