System and method for treating water recycled from straw pulp papermaking wastewater

A technology for papermaking wastewater and treatment system, which is applied in processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Scaling and contamination issues, high modernity, high operability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

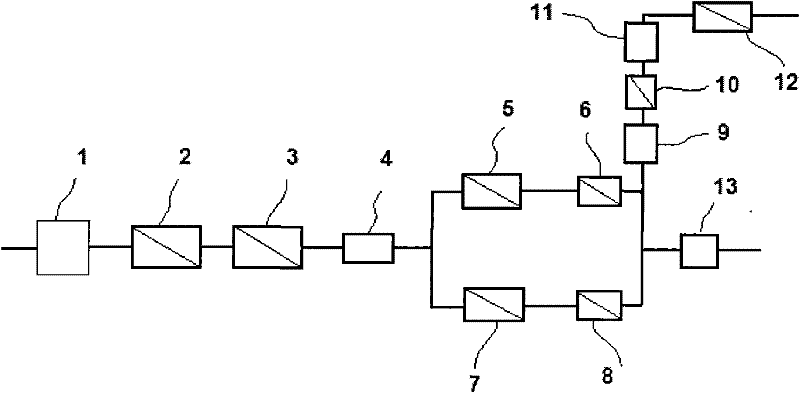

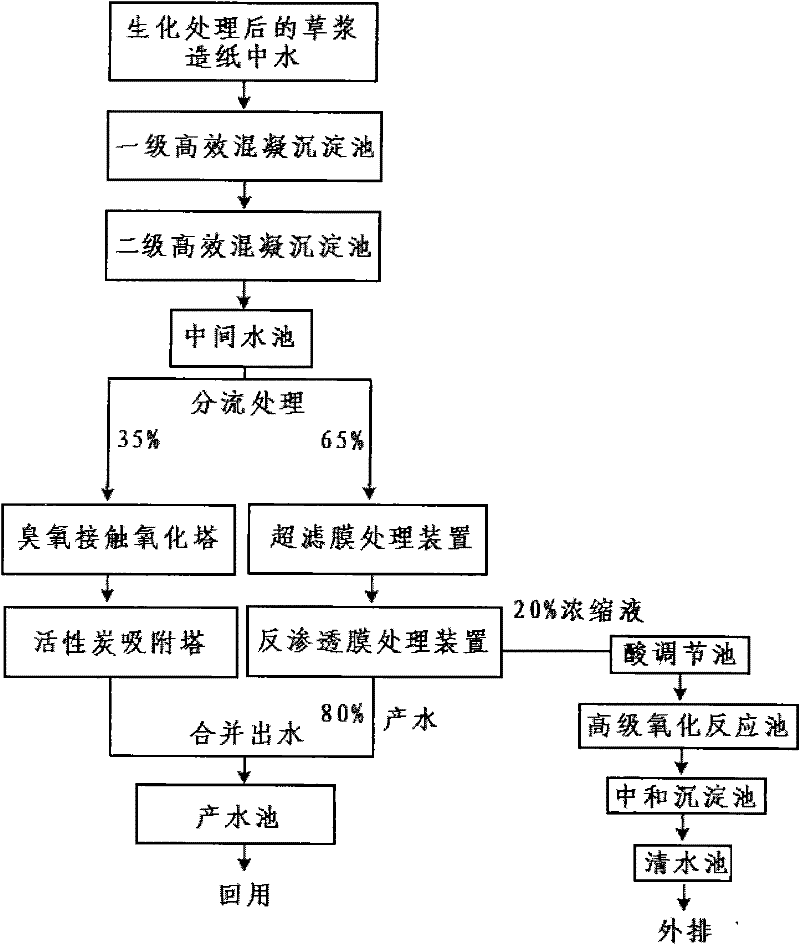

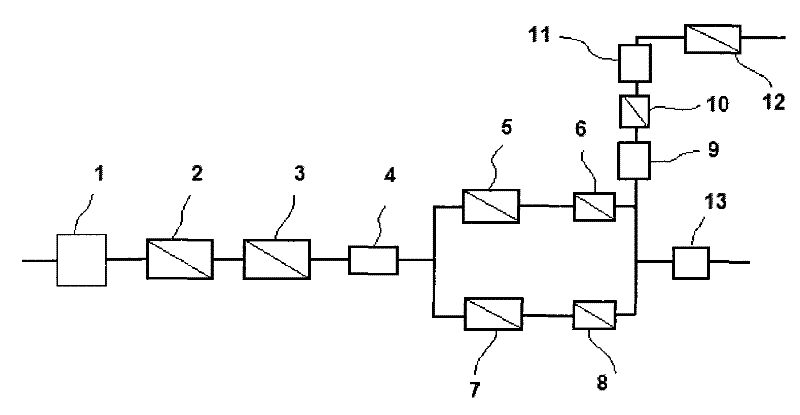

[0026] This embodiment one provides a water reuse treatment system for straw pulp papermaking wastewater, such as figure 1 As shown, the system consists of a first-level high-efficiency coagulation-settling tank (pre-coagulation tank, coagulation reaction tank, coagulation-settling tank), a second-level high-efficiency coagulation-settling tank (pre-coagulation tank, coagulation reaction tank, coagulation sedimentation tank), intermediate tank (sand filter), ultrafiltration membrane treatment unit, reverse osmosis membrane treatment unit, ozone contact oxidation tower, activated carbon adsorption tower, acid conditioning tank, advanced oxidation reaction tank, neutralization sedimentation tank, clear water tank and product pool together;

[0027]Among them, the adjustment tank is connected with the first-level high-efficiency coagulation-sedimentation tank, the second-level high-efficiency coagulation-sedimentation tank and the intermediate pool in turn. The adjustment tank is...

Embodiment 2

[0036] This embodiment provides a treatment method for reclaimed water from straw pulp and papermaking wastewater. The treatment system in the first embodiment above can be used to treat the reclaimed water of straw pulp and papermaking wastewater treated by biochemical methods. The treatment method includes the following step:

[0037] Primary coagulation and sedimentation treatment: the biochemically treated straw pulp and papermaking reclaimed water is subjected to coagulation and sedimentation treatment in the primary coagulation and sedimentation tank of the treatment system. During the coagulation and sedimentation treatment, three Any one of ferric chloride powder or polyferric sulfate is used as coagulant;

[0038] During treatment, any one of ferric chloride powder or polyferric sulfate is dry-dosed into the reclaimed water treated in the pre-coagulation tank of the first-level high-efficiency coagulation sedimentation tank, and the dosage is 0.08g~0.16g / L, the stir...

Embodiment 3

[0072] In this embodiment, the treatment system described in Embodiment 1 is used in combination with the treatment method described in Embodiment 2 to carry out a specific treatment process for the biochemically treated effluent discharged from a certain straw pulp paper mill, and to make a comparison of the embodiment of the present invention. To further illustrate, the effluent from the biochemical reaction tank of the straw pulp and paper mill enters the pre-coagulation part of the first-level high-efficiency coagulation and sedimentation treatment through a first-level lift, and ferric chloride powder is added through a dry powder doser. The dry powder dosage 0.08-0.16g / L to achieve effective removal of suspended particulate matter, organic matter, silicate-based dissolved solids, etc. Due to the hydrolysis of iron, the pH of the water body will decrease. After stirring, the solution directly enters the coagulation reaction tank of the first-level high-efficiency coagulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com