Plant leaf surface brightening cleanser

A cleaning agent and foliar technology, applied in the field of plant foliar cleaning, can solve the problems of plant foliar damage, ion concentration on foliar surface, affecting plant respiration and photosynthesis, and inability to use plant foliar cleaning, etc. Protects and promotes repair, increases protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

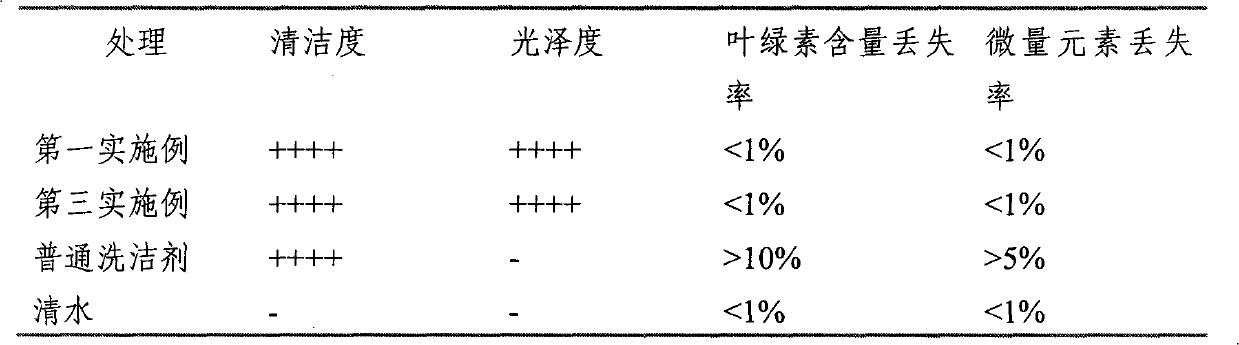

Examples

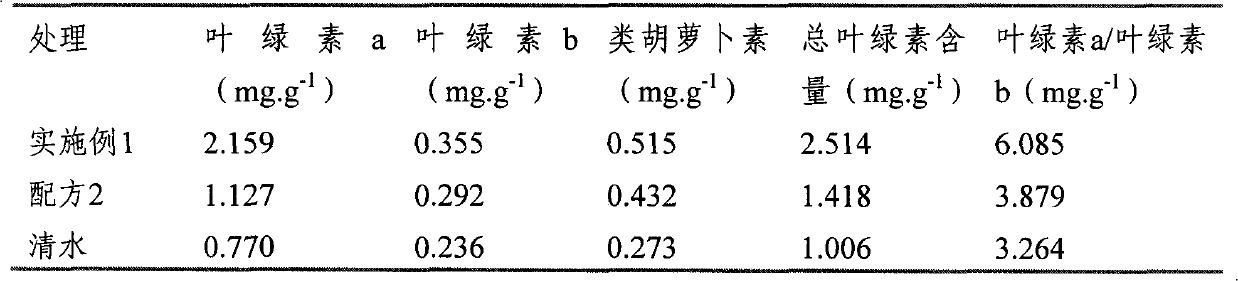

no. 1 example

[0010] A plant foliar cleaner, including the following components in weight:

[0011] Sodium laurate 10g;

[0012] Cocoyl diethanolamine 8g;

[0013] Sodium hyaluronate 0.6g

[0014] Citric acid 0.03g;

[0015] Ethanol 1g

[0016] Sodium benzoate 0.01g;

[0017] Deionized water 70g.

[0018] The preparation process of the first embodiment of the present invention is as follows:

[0019] (1) Add 10 grams of sodium laurate, 8 grams of coconut acid diethanolamine and 70 grams of deionized water into a mixer and stir for 2.5 hours, and the temperature is controlled at 50°C.

[0020] (2) Cool the product obtained in step (1) to 30°C, add 0.6 g of sodium hyaluronate, 0.03 g of citric acid, 0.01 g of sodium benzoate, and 1 g of ethanol, and continue stirring for 0.5 hours to obtain the product of the present invention.

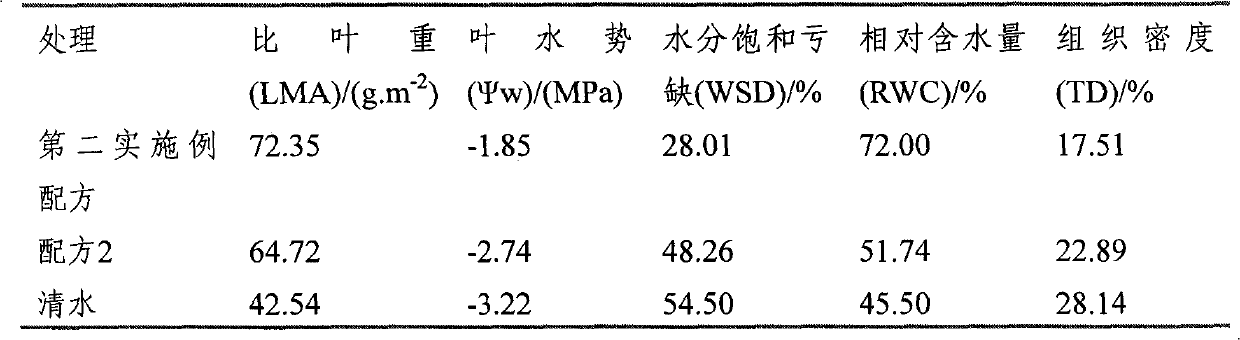

no. 2 example

[0022] A plant foliar cleaner, including the following components in weight:

[0023] Fatty alcohol polyoxyethylene ether sodium sulfate 10g;

[0024] Alkylbenzene sulfonate 3g

[0025] Tea saponin 5g;

[0026] Alkyl polyglycoside 4g

[0027] Hyaluronic acid 0.1g;

[0028] Citric acid 0.1g;

[0029] Ethylene glycol 0.5g

[0030] Methyl hydroxybenzoate 0.1g

[0031] Potassium sorbate 0.1g;

[0032] 65g deionized water;

no. 3 example

[0034] A plant foliar cleaner, including the following components in weight:

[0035] Alkylbenzene sulfonate 5g

[0037] Potassium laurate 8g

[0038] Polyoxyethylene amide 2g

[0039] Polyoxyethylene fatty amine 6g

[0040] Alkylbenzene sulfonate 1g

[0042] Propylene glycol 0.4g

[0043] Ethylene glycol 0.3g

[0044] Zinc Hyaluronate 0.5g

[0045] Ammonium hyaluronate 0.6g

[0046] Citric acid 0.3g

[0047] Methyl hydroxybenzoate 0.3g

[0048] Propylparaben 0.2g

[0049] Deionized water 82g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com