Method for synthesizing para aminophenylmethylether by catalytic hydrogenation of paranitroanisole

A technology for p-nitroanisole and p-aminoanisole is applied in the field of catalyzing p-nitroanisole hydrogenation to synthesize p-aminoanisole with a supported palladium catalyst, and can solve the problem of waste disposal difficulties and high reaction temperature , short process flow and other problems, to achieve the effect of being conducive to environmental protection, mild reaction conditions, and clean reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

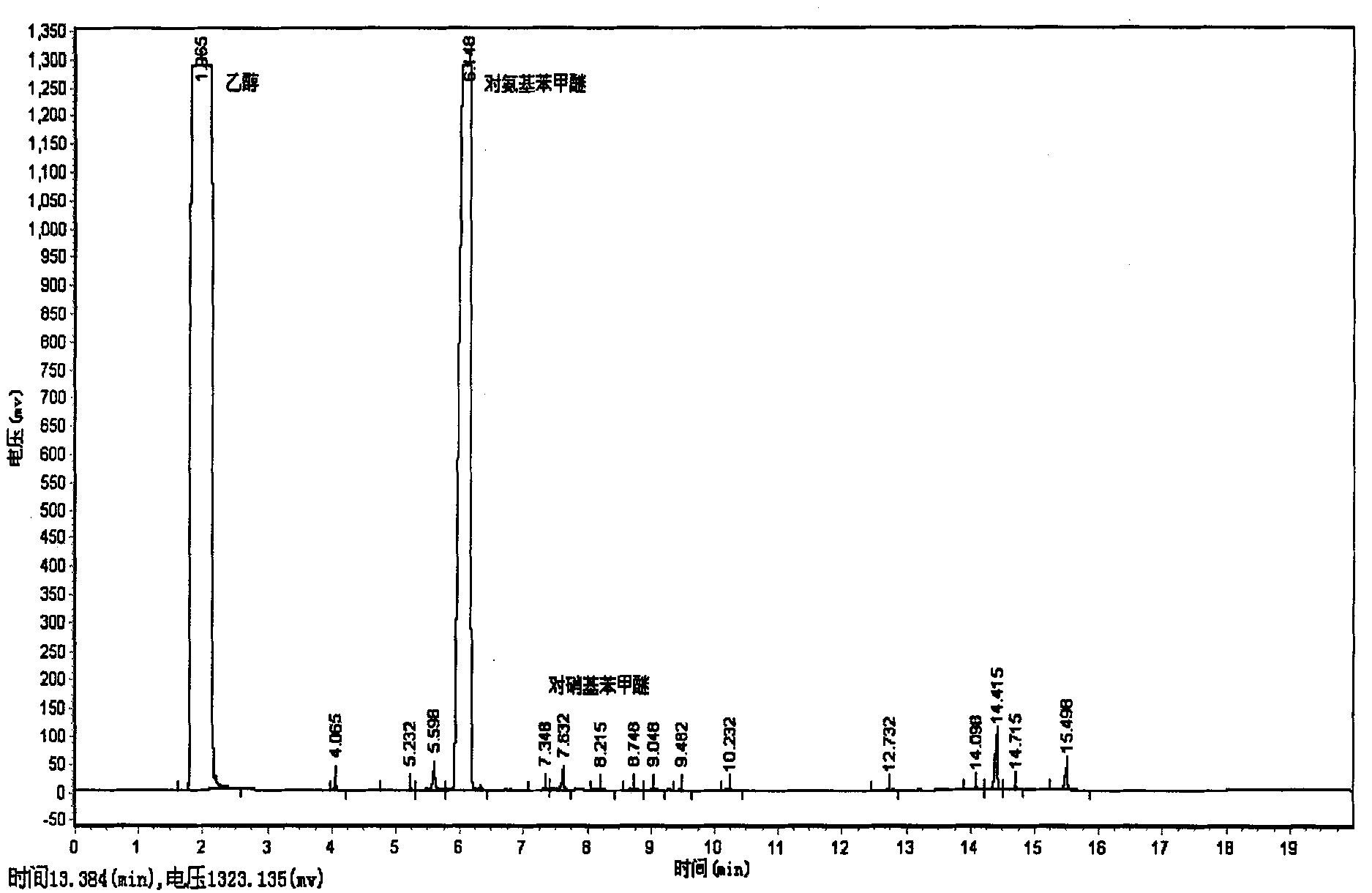

Embodiment 1

[0014] (1), add 0.306 gram of p-nitroanisole (analytical pure) and 0.0015 gram of Pd / C catalyst (the mass fraction of Pd is 5%) in 50 milliliters of autoclaves, at room temperature use carbon dioxide to sweep, discharge Air in the empty reaction system;

[0015] (2), the reactor is heated to 40 DEG C; Charge hydrogen into the reactor, and the pressure in the reactor is 2 MPa; Then charge into carbon dioxide, the pressure in the reactor is 14 MPa; Stir, and the reaction time is 10 MPa Minutes; After the reaction, naturally cool to room temperature, filter, and separate the product to obtain p-aminoanisole. The yield thereof was 25.51%.

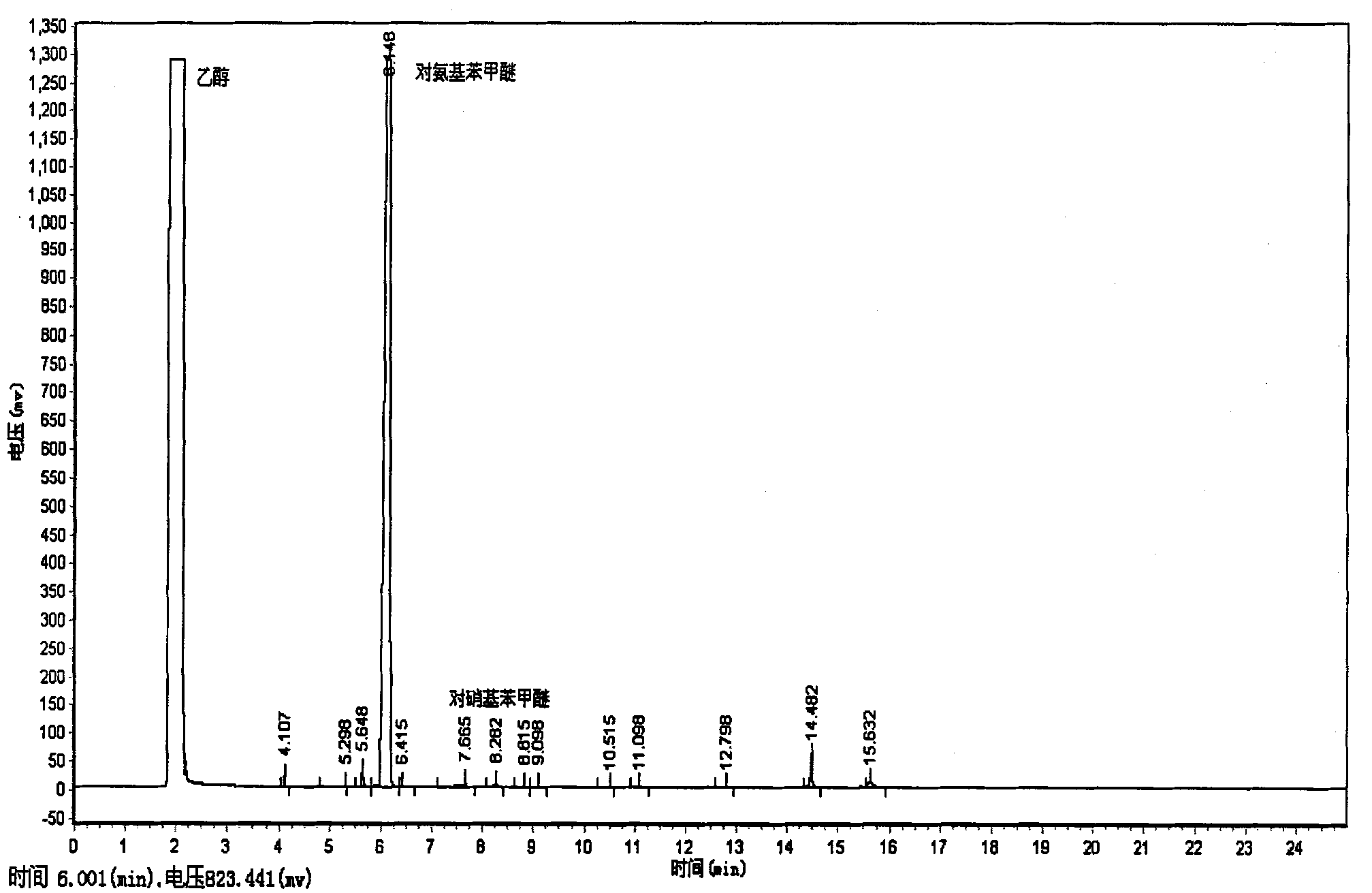

Embodiment 2

[0017] (1) with embodiment 1;

[0018] (2), the reactor is heated to 60 DEG C; Charge hydrogen into the reactor, and the pressure in the reactor is 4 MPa; Then charge into carbon dioxide, the pressure in the reactor is 16 MPa; Stir, and the reaction time is 10 MPa Minutes; After the reaction, naturally cool to room temperature, filter, and separate the product to obtain p-aminoanisole. The yield is 98.87%.

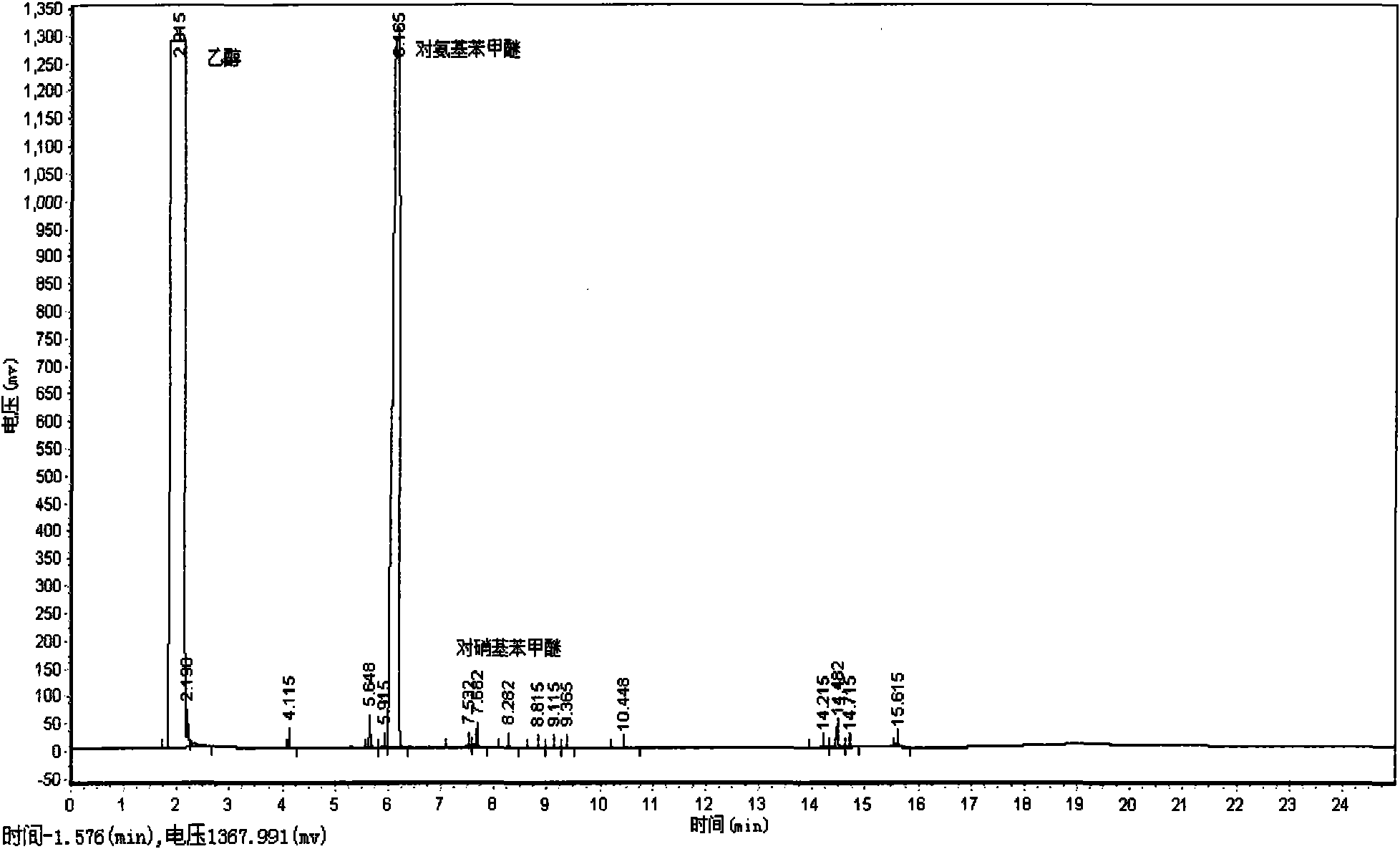

Embodiment 3

[0020] (1) with embodiment 1;

[0021] (2), the reaction kettle is heated to 60 ℃; In the reaction kettle, charge hydrogen, the pressure in the reaction kettle is 1 MPa; Then charge into carbon dioxide, the pressure in the reaction kettle is 13 MPa; Stir, the reaction time is 20 Minutes; after the reaction, naturally cool to room temperature, filter, isolate the product, and obtain p-aminoanisole yield of 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com