Graphene-supported cobaltosic oxide nano composite material and preparation method thereof

A technology of cobalt tetroxide nanometer and cobalt tetroxide, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of large particle size of cobalt tetroxide and poor conductivity of the carrier, and achieve the effects of good conductivity, controllable particle size and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 0.5 grams of graphite oxide and add 2 kilograms of deionized water and stir for 0.5 hours to prepare a graphene oxide solution, add 0.5 grams of polyvinylpyrrolidone, stir for 1 hour, then add 2 grams of cobalt nitrate hexahydrate, and stir for 1 hour;

[0026] Dissolve 0.5 g of sodium hydroxide in 200 g of deionized water, add 1 g of hydrogen peroxide, and stir for 1 hour;

[0027] The above two solutions were mixed and stirred for 2 hours, then transferred to a high-temperature reaction kettle, and annealed at 110 degrees Celsius for 10 hours to obtain the product; the product was filtered and washed several times or centrifugally washed, and then dried to obtain a graphene-supported cobalt tetraoxide nanocomposite material .

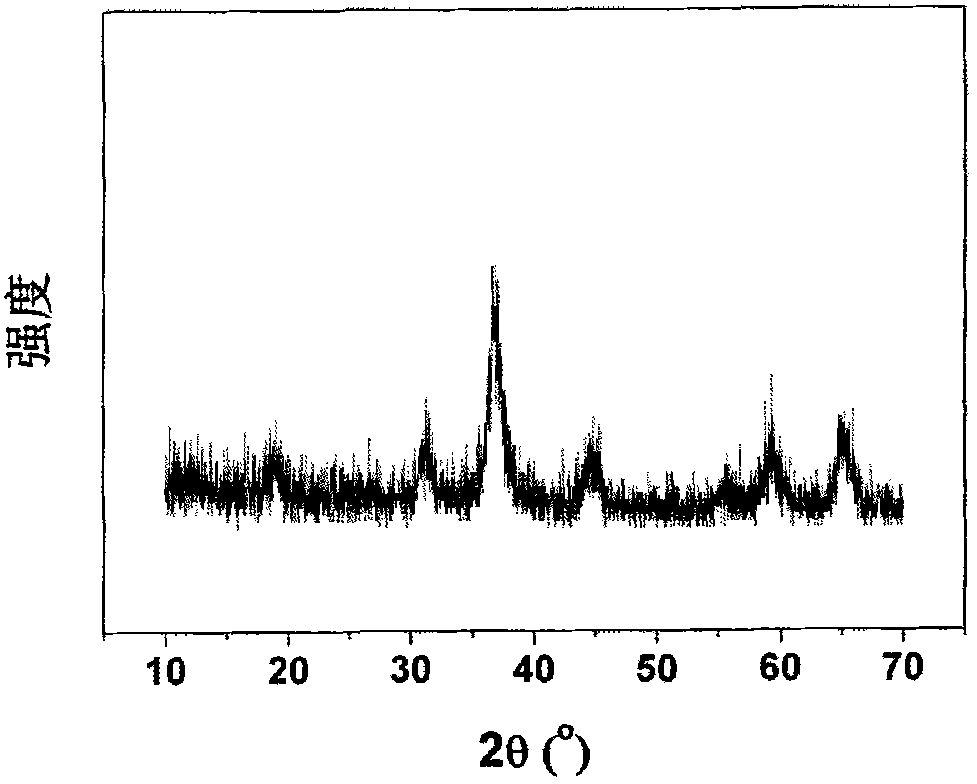

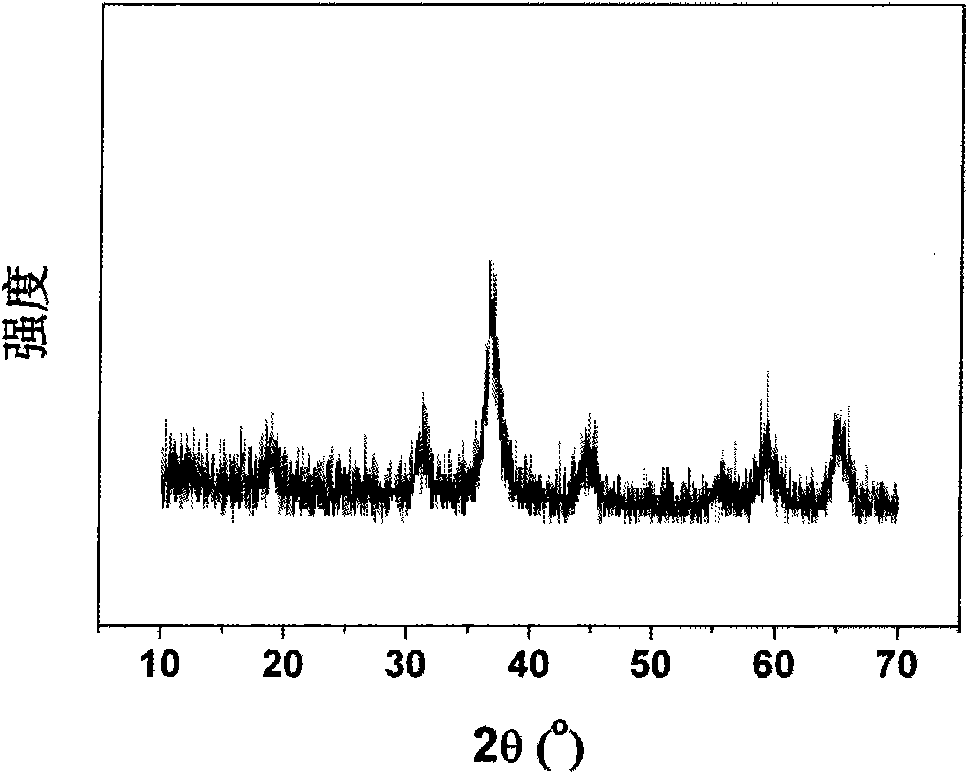

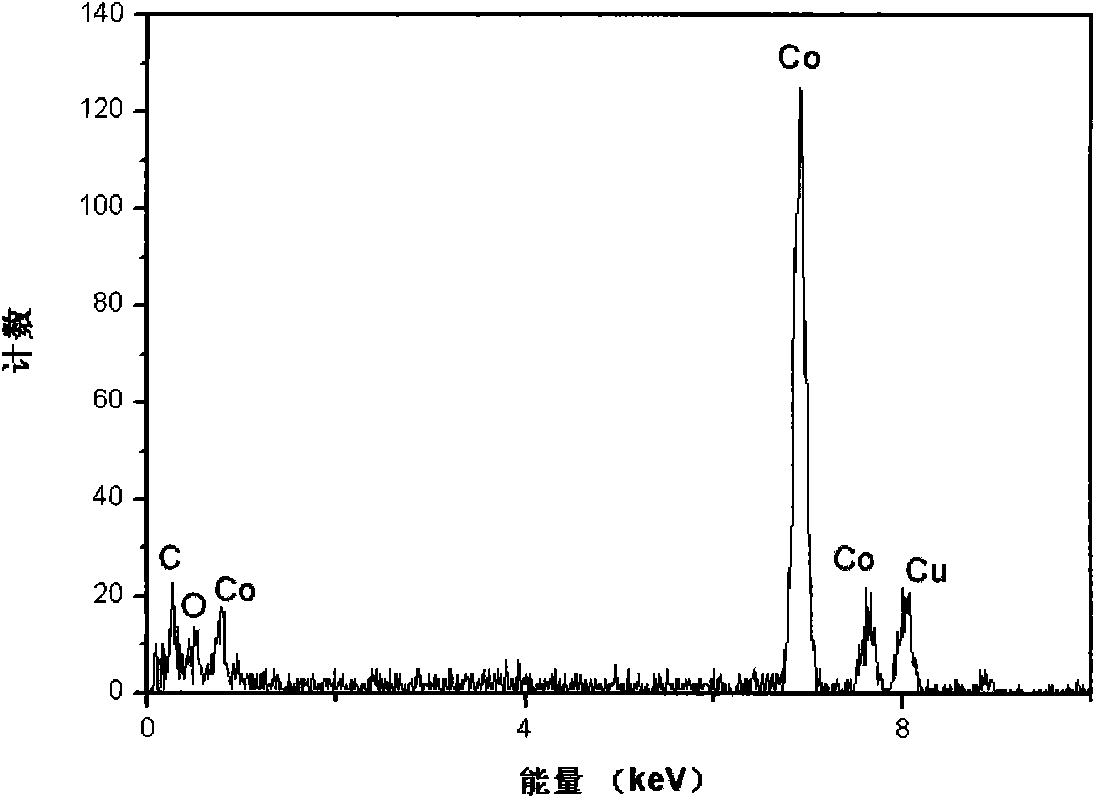

[0028] The graphene-loaded cobalt tetroxide composite material samples obtained in this example were tested by various instruments, and the test results are shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4 in the accompanying drawings.

[0029]...

Embodiment 2

[0035] Take 0.05 g of graphite oxide and add it to 1 kg of deionized water and stir for 2 hours to prepare a graphene oxide solution, then add 2 g of cobalt chloride hexahydrate and stir for 0.5 hour;

[0036] Dissolve 0.5 g of potassium hydroxide in 200 g of deionized water, add 1 g of hydrazine monohydrate, and stir for 0.5 hours;

[0037] The above two solutions were mixed and stirred for 1 hour, then transferred to a high-temperature reaction kettle, and annealed at 200 degrees Celsius for 5 hours; the product was filtered, washed, and dried to obtain a graphene-supported cobalt tetraoxide nanocomposite material, wherein the graphene nanosheet The mass fraction is 7%, the thickness of the graphene nanosheet is 1 nanometer, and the particle diameter of tricobalt tetroxide is 100 nanometers.

[0038] The graphene-loaded cobalt tetroxide composite material sample obtained in this example has the same X-ray diffraction results and energy spectrum analysis results as in Example...

Embodiment 3

[0043] Take 1 gram of graphite oxide and 2 grams of sodium dodecylbenzenesulfonate and add 100 grams of deionized water and stir for 4 hours to prepare a graphene oxide solution, then add 0.5 gram of cobalt acetate and stir for 0.5 hours;

[0044] Dissolve 1 gram of 30% ammonia water in 500 grams of deionized water, add 1 gram of potassium chlorate, and sonicate for 0.5 hours;

[0045] The above two solutions were mixed and stirred for 5 hours, then transferred to a high-temperature reaction kettle, and annealed at 250 degrees Celsius for 15 hours; the product was filtered, washed, and dried to obtain a graphene-supported cobalt trioxide nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com