Wrapped low-moisture rapid-orientation fermented straw nutrition forage grass

A technology for fermenting straw and low moisture, which is applied in animal feed, animal feed, microorganisms, etc., can solve the problems such as the reduction of the relative concentration of forage grass, the loss of straw storage, and the effect of feeding and increasing production. The effect of promoting quality improvement and significant feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

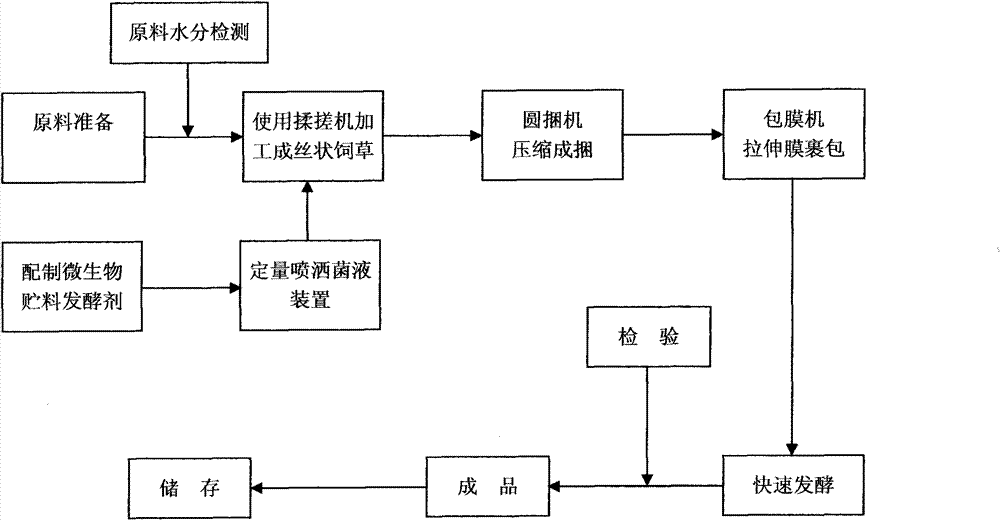

Image

Examples

Embodiment Construction

[0036] 1. Main material preparation: use a straw kneading machine to process corn stalks with a water content of 25% into 5cm filaments, and prepare 1000 grams of raw materials;

[0037] 2. Preparation of straw bio-storage preparation: Small filamentous fungi, Bacillus subtilis and Lactobacillus acidophilus were obtained by solid fermentation culture and liquid fermentation culture respectively

[0038] The above three kinds of dried thallus, and then these three kinds of dried thallines are uniformly mixed according to the weight ratio of 2:1:1, and then the straw bio-storage preparation agent is made.

[0039] 1. Obtaining dried cells of small filamentous fungi by solid fermentation culture method: the method and steps are as follows:

[0040] 1.1 Various raw materials in the solid medium: wheat bran: 800 grams; sodium acetate: 1 gram; rice straw powder: 170 grams; calcium chloride: 3 grams; cellulose-123: 10 grams; copper sulfate: 1 gram; sulfuric acid 5 grams of ammonium;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com