Preparation method of high-dispersion zirconium oxide nano powder

A technology of nano-powder and zirconia, which is applied in zirconia, nano-structure manufacturing, nano-technology, etc., can solve problems such as low surface tension, high cost of organic solvents, and large investment in equipment, so as to improve powder dispersion and facilitate The effect of industrialized production and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) 3.2g of ZrOCl 2 ·8H 2 O is dissolved in the water of 100ml and is configured into 0.1mol / L zirconium oxychloride solution, under stirring condition, 0.2mol / L sodium borohydride solution is titrated in the zirconium oxychloride solution, generates gel, then gel is used Deionized water was suction-filtered and washed several times until the lotion was neutral to obtain 12g of gel; (2) 12g of camphene was added to the gel, and mixed by ball milling at 50°C to form a slurry; (3) at room temperature After solidification and molding, the solidified slurry is left in the air environment at room temperature for 7 days. After the camphene is completely volatilized, it is placed in a sintering furnace and calcined at 700°C to obtain highly dispersed zirconia nanopowder.

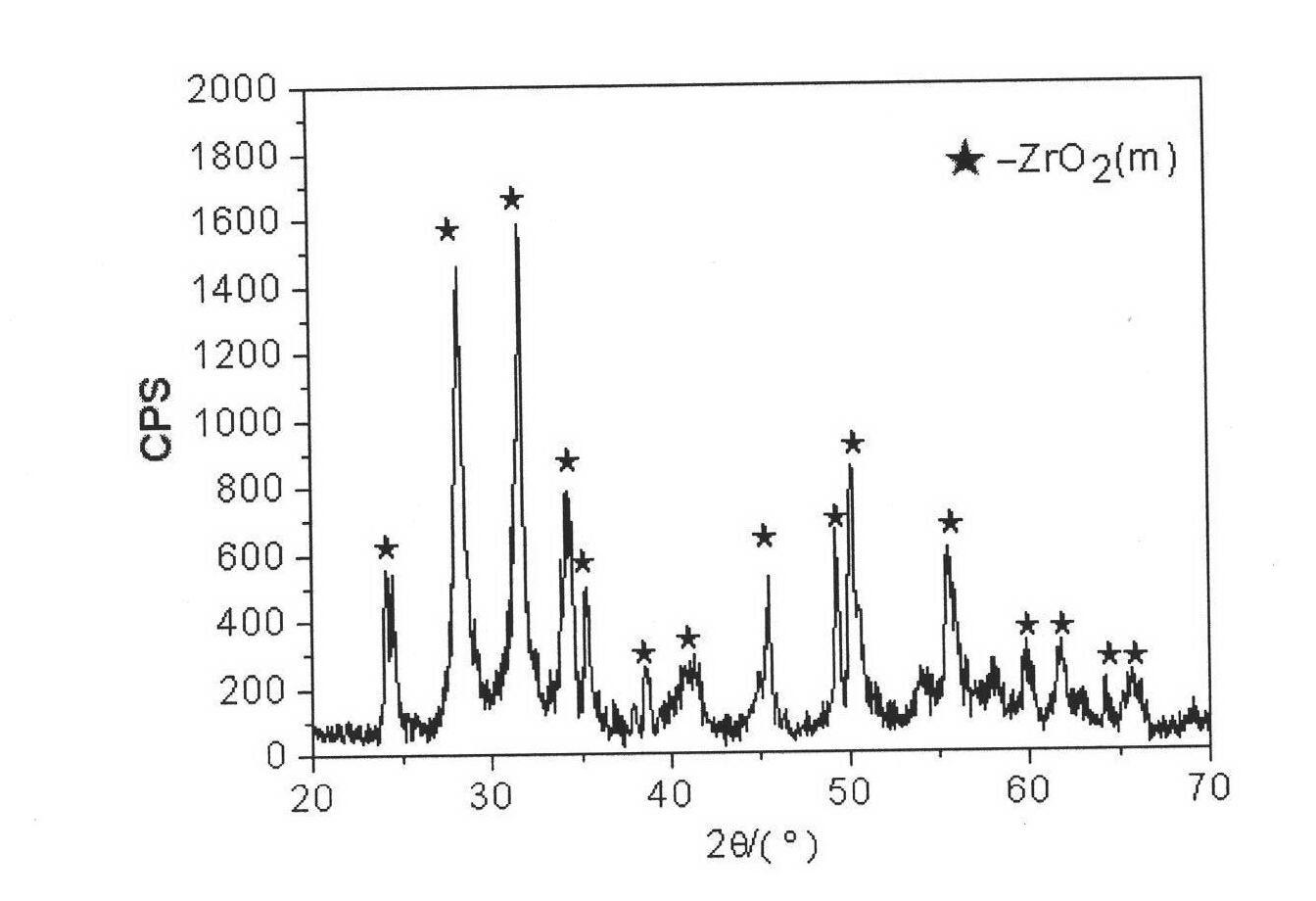

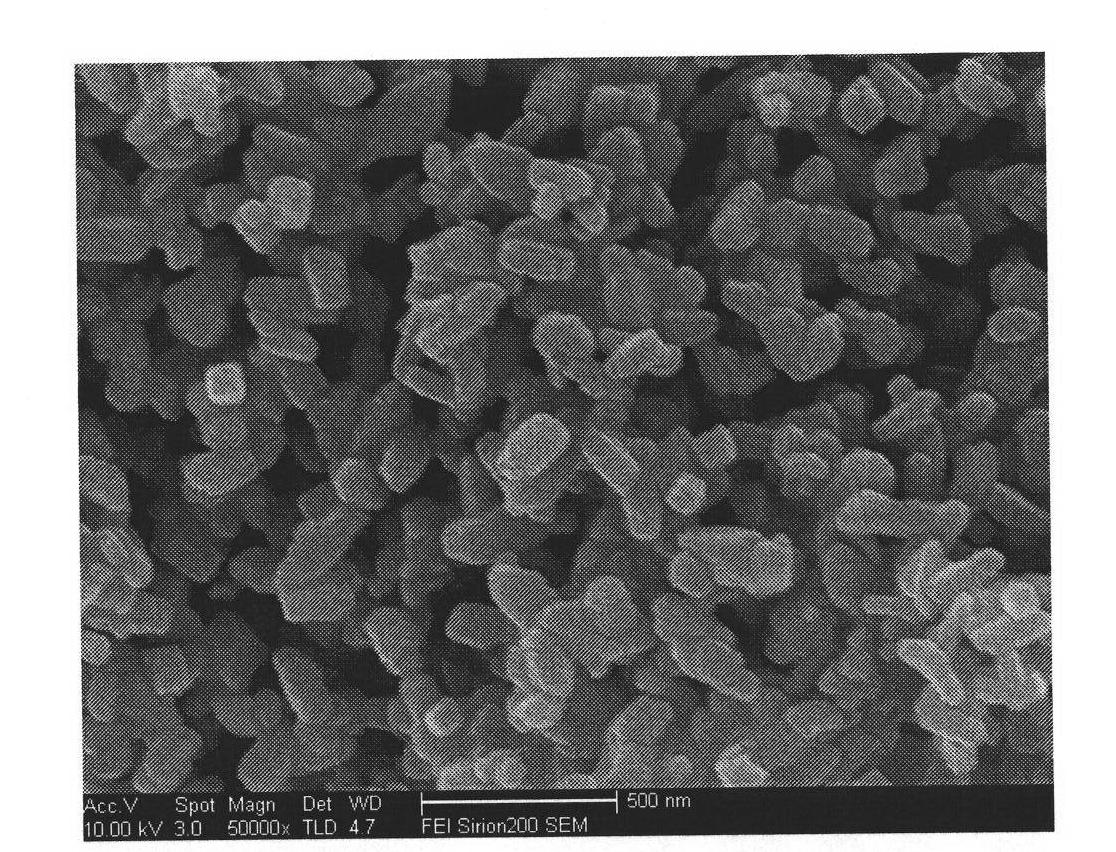

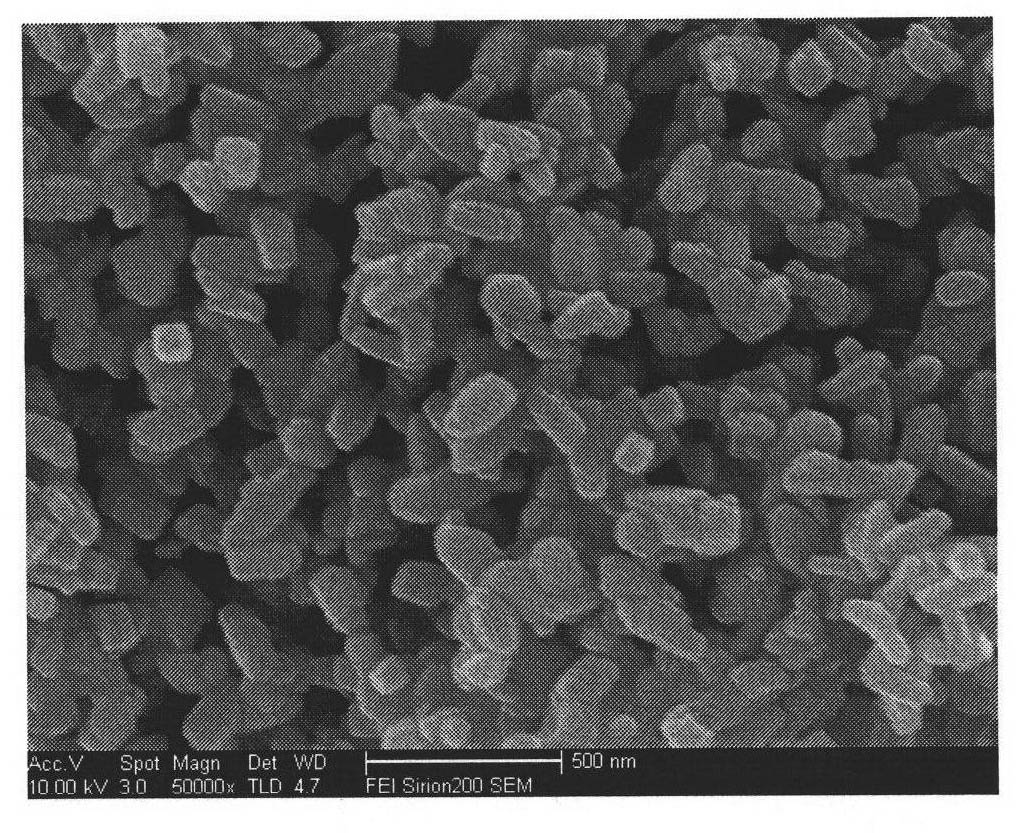

[0017] Through XRD test, it can be seen that the powder crystal type is monoclinic phase; through SEM test, it can be seen that the particle size of zirconia nano powder is about 40nm, without hard agglomer...

Embodiment 2

[0019] (1) 4.3g of Zr(NO 3 ) 4 ·5H 2 O is dissolved in 100ml of water to form a 0.1mol / L zirconium nitrate solution. Under agitation, titrate a 0.5mol / L sodium borohydride solution into the zirconium nitrate solution to form a gel, and then extract the gel with deionized water. Filter and wash several times until the lotion is neutral to obtain 20g of gel; (2) add 20g of camphene to the gel, and mix it by ball milling at 50°C to form a slurry; (3) solidify and form at room temperature, and The solidified slurry is placed in the air environment at room temperature for 7 days, and after the camphene is completely volatilized, it is placed in a sintering furnace and calcined at 700°C to obtain highly dispersed zirconia nanopowder.

Embodiment 3

[0021] (1) 9.6g of ZrOCl 2 ·8H 2 O is dissolved in 100ml of water to form a 0.3mol / L zirconium oxychloride solution. Under stirring conditions, titrate 1mol / L ammonium carbonate solution into the zirconium oxychloride solution to form a gel, and then deionize the gel Water was filtered and washed several times until the lotion was neutral, and 45 g of gel was obtained; (2) 90 g of camphene was added to the gel, and mixed by ball milling at 60 ° C to form a slurry; (3) solidified at room temperature , put the solidified slurry in the air environment at room temperature for 7 days, after the camphene is completely volatilized, put it in a sintering furnace, and calcined at 800 ° C to obtain highly dispersed zirconia nanopowder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com