Preparation method of lithium manganate precursor for lithium ion battery anode material

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, manganate/permanganate, circuits, etc., to achieve the effects of no three-waste emissions, improved electrochemical cycle performance, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

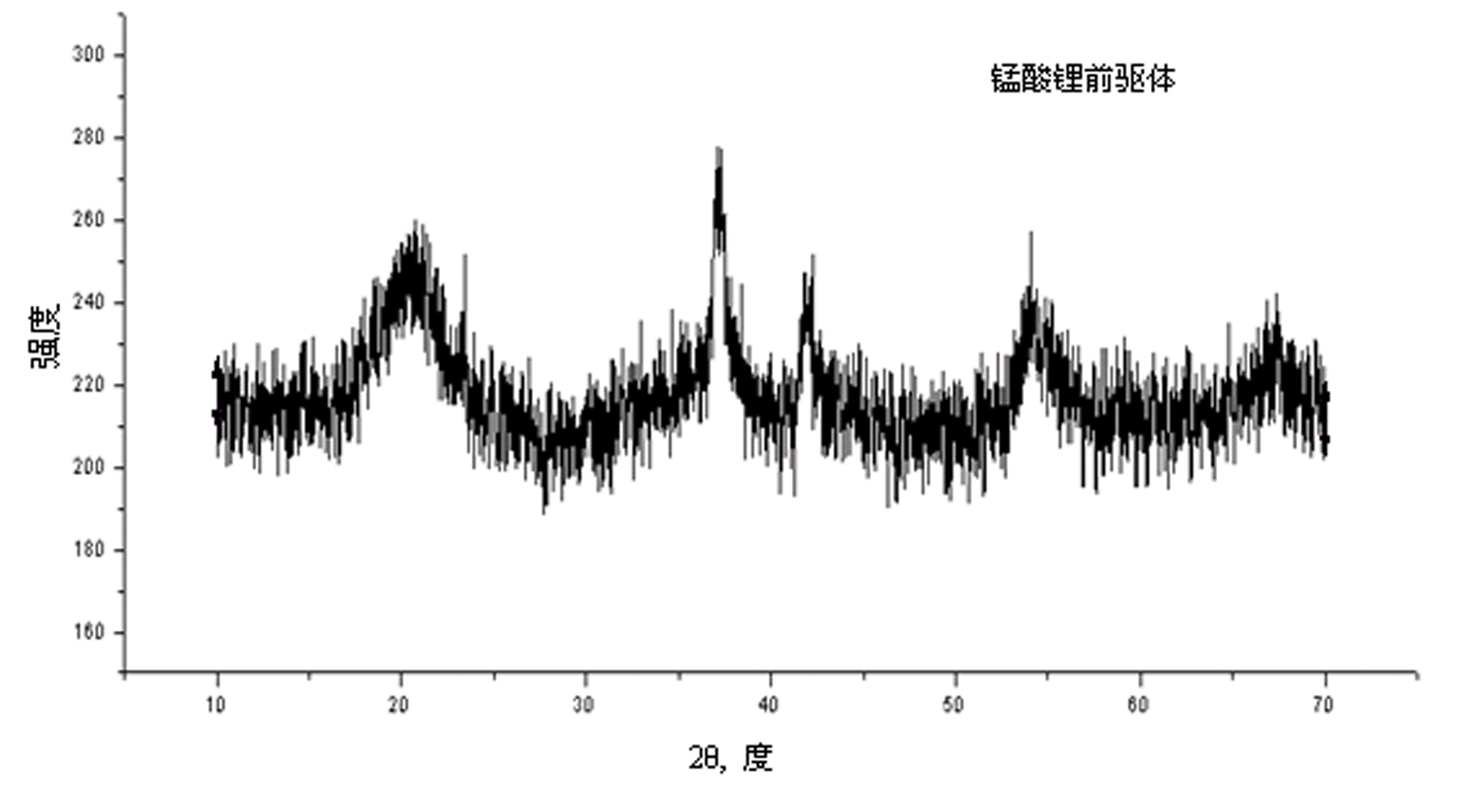

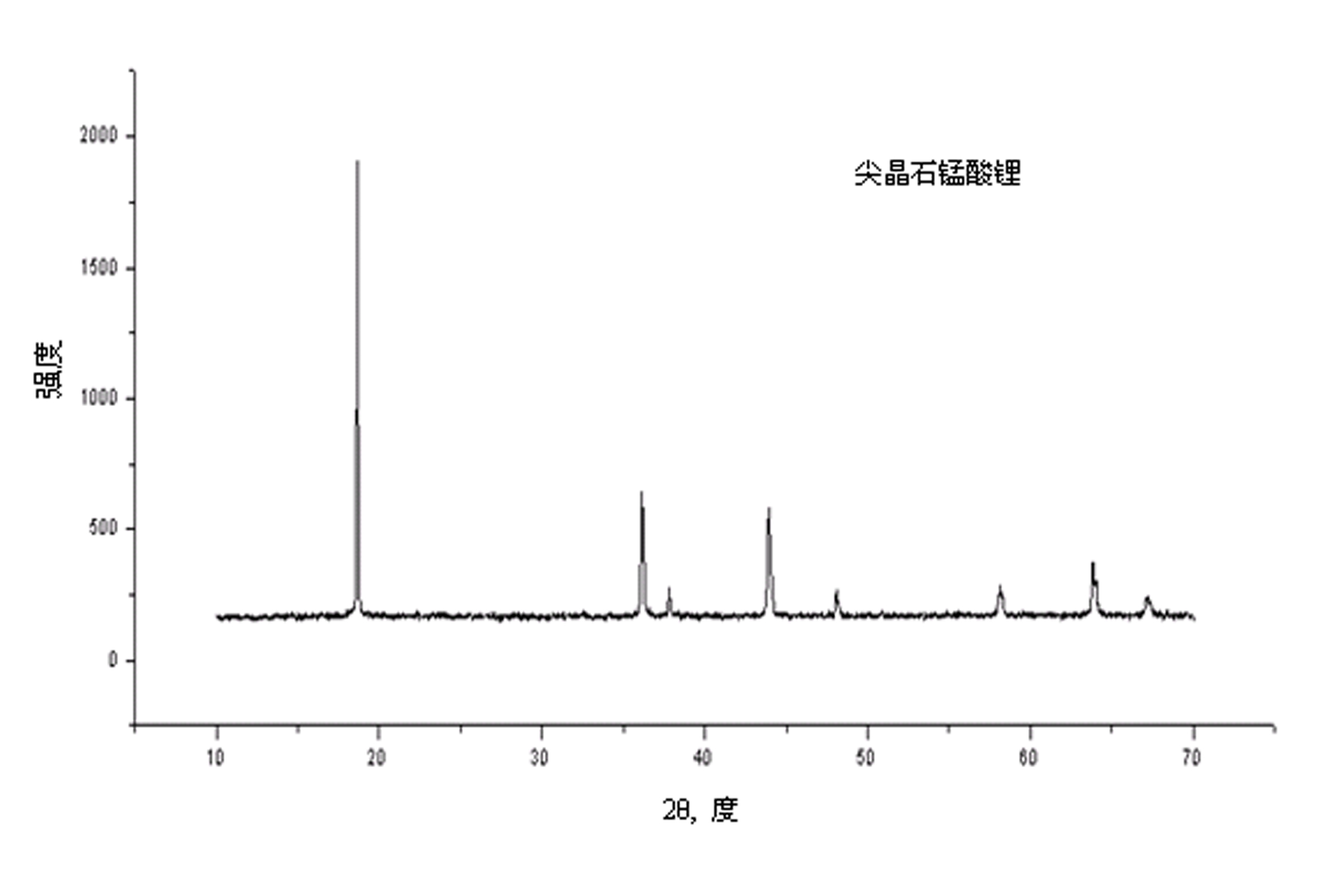

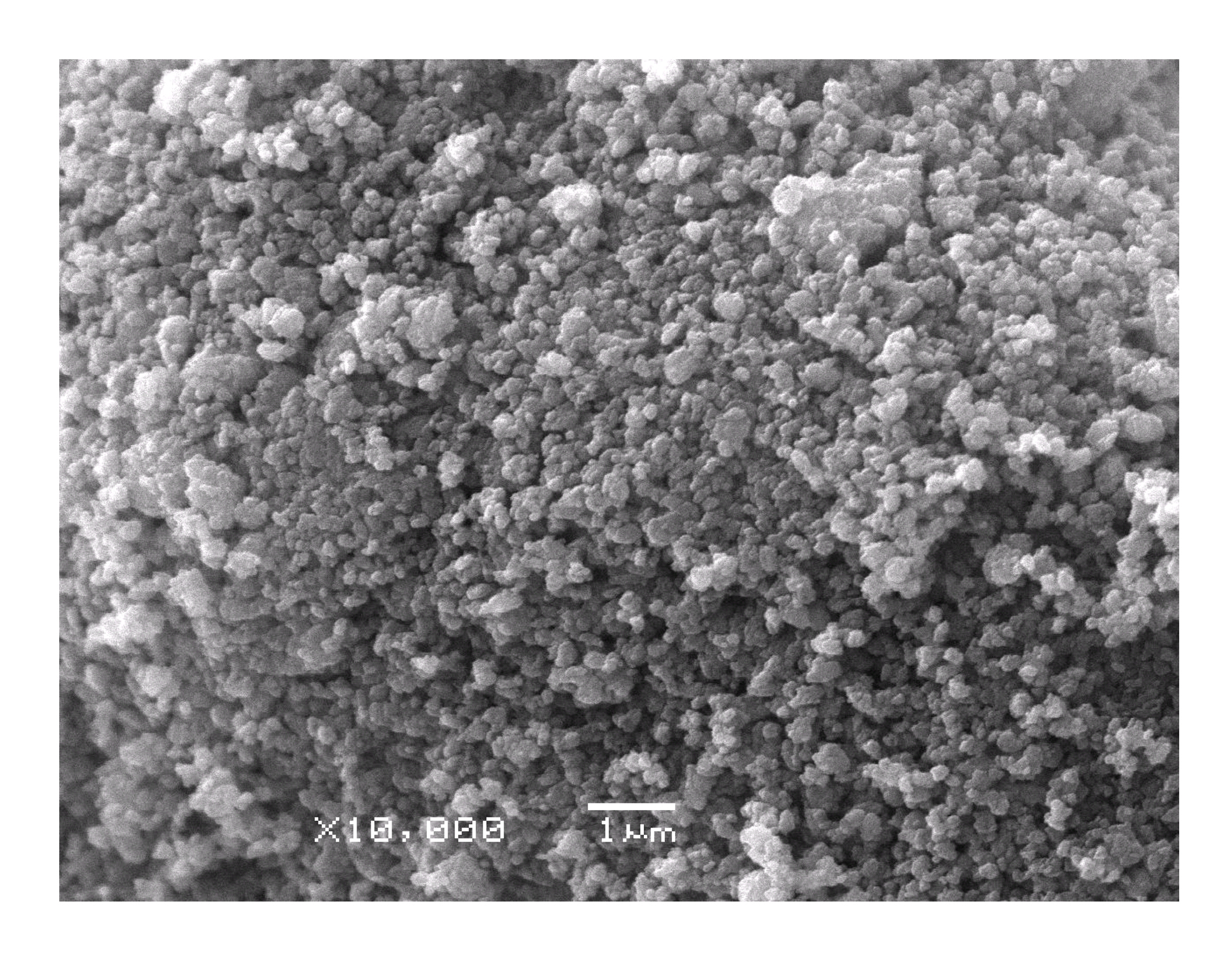

[0026] Example 1 : (1) 600g electrolytic MnO 2 , 179.3g LiOH·H 2 O and 480g deionized water are mixed with reactant slurry, add in the autoclave (Li / Mn mol ratio is 0.62, liquid-solid weight ratio H 2 O / MnO 20.8); (2) While stirring, heat up to 180°C, and stir for 3 hours at a constant temperature; (3) Filter the reaction product slurry obtained in step (2), and dry the solid phase product at 110°C for 12 hours, 655.2g of lithium manganate precursor was obtained, and its Li / Mn ratio satisfied the molecular formula Li 1.100 mn 2 o 4 ; The volume of the liquid phase mother liquor is 420 mL, containing Li 1.2mol / L, returning to prepare the next batch of reactant slurry. Gained lithium manganate precursor shows through XRD analysis, has amorphous structure (see attached figure 1 ), and its morphology under the electron microscope is shown in the appendix image 3 . The obtained lithium manganate precursor was heat-treated at 800° C. for 10 hours, ground and pulverized a...

Embodiment 2

[0027] Example 2 : (1) Get 200mL of the mother liquor gained in Example 1 (Li 1.2mol / L), add LiOH·H 2 O 18.8g, then add chemical MnO 2 200g, be mixed with reactant slurry, add in the reactor (Li / Mn molar ratio is 0.3, liquid-solid weight ratio H 2 O / MnO 2 1.0); (2) While stirring, raise the temperature to 200°C, stir and react at a constant temperature for 2.5 hours; (3) Dry the reaction product slurry obtained in step (2) at 120°C for 24 hours to obtain a lithium manganate precursor 213.8 g, whose Li / Mn ratio satisfies the molecular formula Li 0.605 mn 2 o 4 . XRD analysis shows that the lithium manganese oxide precursor has an amorphous structure. The lithium manganate precursor was heat-treated at 750° C. for 12 hours, ground and pulverized after cooling to obtain lithium manganate powder. XRD analysis shows that the phase structure of the powder is mainly spinel lithium manganese oxide, containing a small amount of MnO 2 . The results of chemical analysis show ...

Embodiment 3

[0028] Example 3 : (1) 200g electrolytic MnO 2 , a mixture of 4.6 mol of lithium acetate and lithium hydroxide and 600 g of deionized water to prepare a reaction slurry and add it to the reactor (Li / Mn molar ratio is 2.0, liquid-solid weight ratio H 2 O / MnO 2 3.0); (2) While stirring, the temperature was raised to 110°C, and the stirring was carried out at a constant temperature for 12 hours; (3) After the reaction product slurry obtained in step (2) was filtered to remove the mother liquor, it was dried at 105°C for 12 hours. hours, 225.6g of lithium manganate precursor was obtained, and its Li / Mn ratio satisfied the molecular formula Li 0.971 MnO 2 . The obtained lithium manganate precursor was placed in a high-temperature furnace, heat-treated at a constant temperature of 800° C. for 15 hours, ground and pulverized after cooling. It was proved by XRD detection that the obtained product was lithium manganese oxide with layered structure. Chemical analysis shows that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com