Compound Janus colloid particle and modified Janus colloid particle as well as preparation methods thereof

A particle modification technology, which is applied in the preparation of polymers, metal oxide composite Janus colloidal particles, inorganic substances, and metals, and can solve the problems that cannot be produced in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

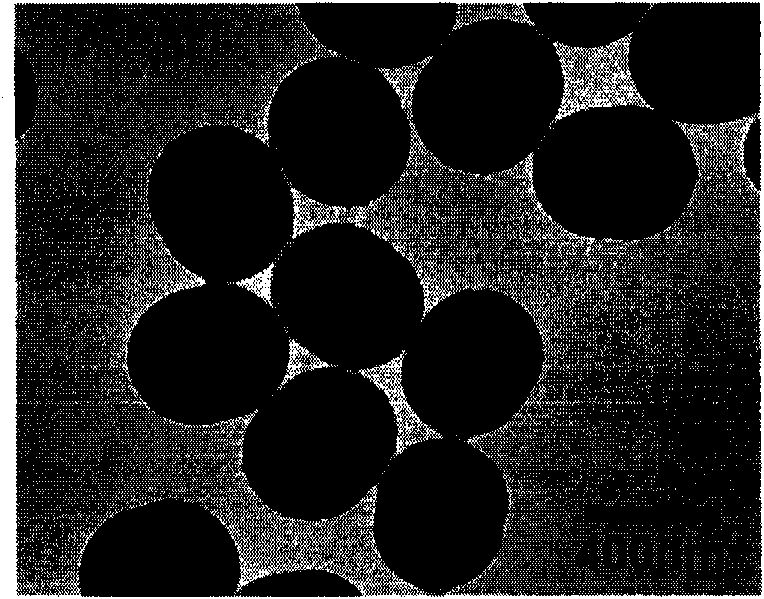

[0067] Example 1, SiO 2 Preparation of / PS Janus particles

[0068] 1g SiO 2 (diameter 400nm) spherical particles dispersed in 10g ethanol, 1g water, 0.3g vinyltriethoxysilane mixed solution, ultrasonically dispersed evenly, stirred and reacted at 25°C for 10 hours, after the reaction, centrifuged with ethanol to wash away unreacted A silane coupling agent. 1g modified SiO 2 The particles are dispersed in 10g of water, and the ultrasonic dispersion is uniform. In addition, 2g of styrene (St), 2g of divinylbenzene (DVB), 0.5g of sodium dodecylsulfonate (SDS), 0.04g of potassium persulfate (KPS), and 50g of water were mixed and ultrasonically emulsified. Heat the seed system to 80°C, then start to add the emulsion system dropwise at a rate of 0.1ml / min, and keep the temperature for 2 hours after the dropwise addition is completed. After the reaction was completed, the product was washed with ethanol / water centrifugation. Disperse 1g of the product in 5g of 10wt% ammonium f...

Embodiment 2

[0069] Example 2, SiO 2 / TiO 2 Preparation of Janus particles

[0070] Gained SiO in 1g embodiment 1 2 / PS Janus particles are dispersed in 20g of sulfuric acid solution with a concentration of 30wt%, and reacted at 40°C for 5 hours. After the reaction, wash with water until neutral, and freeze-dry to obtain SiO 2 / SPS (sulfonated polystyrene) Janus granules solid powder. Take 1g SiO 2 / SPS Janus particles were dispersed in 1g of tetrabutyl titanate and 5g of absolute ethanol, stirred and adsorbed at room temperature for 10 hours, then centrifuged with absolute ethanol to wash away unadsorbed tetrabutyl titanate, and the particles were dispersed in 10g of Add 1 g of water to ethanol and hydrolyze at room temperature for 5 hours. After the hydrolysis reaction is completed, centrifuge and wash with water, and freeze-dry to obtain a solid powder. 1g of solid powder is placed in a sintering furnace, and in a nitrogen atmosphere, the temperature is raised to 600°C at a rate o...

Embodiment 3

[0071] Example 3, SiO 2 / Fe 3 o 4 Preparation of Janus particles

[0072] Gained SiO in 1g embodiment 2 2 / SPS Janus particles are dispersed in a mixed solution of 10g of ferric chloride (concentration 25wt%) and ferrous chloride (concentration 19wt%), adsorbed at room temperature for 10 hours, then centrifuged with water to remove unadsorbed iron salts, and then dispersed after washing In 10g of ammonia water with a concentration of 15wt%, react at room temperature for 5 hours. After the reaction, centrifuge and wash to obtain SiO 2 / Fe 3 o 4 Janus particles. The product was characterized by SEM, TEM, FTIR and XRD. XRD results show that TiO 2 The crystal form is compound type of anatase and rutile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com