Method for making gradational diffusion photoelectric diode by using MOCVD epitaxial system

A photodiode, gradient type technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problems of large dark current, nonlinear distortion of optical signal detection, inability to make unilateral abrupt junctions and low-ohmic contacts, etc. Small dark current, small capacitance reliability, and the effect of improving chip responsivity and response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

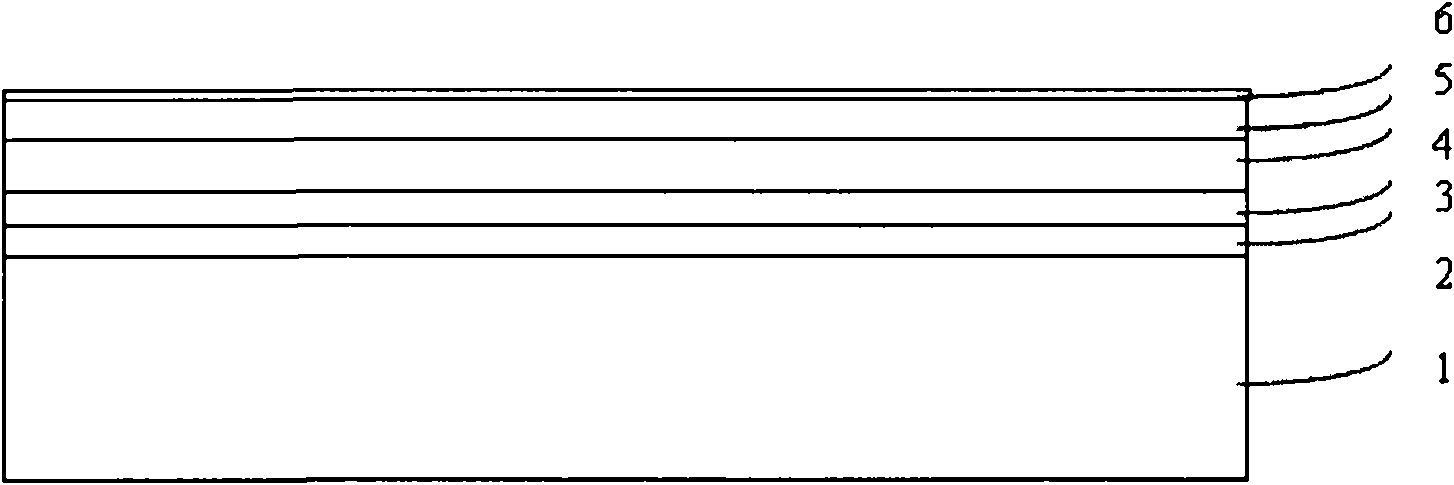

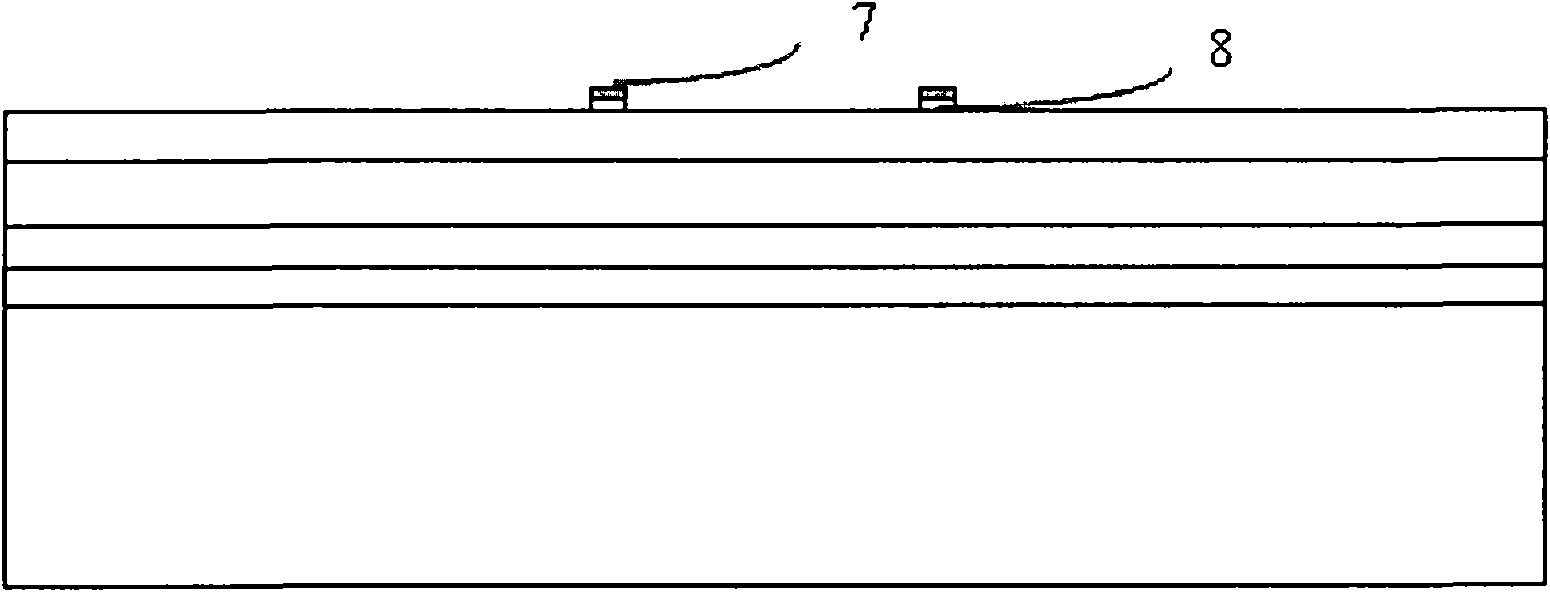

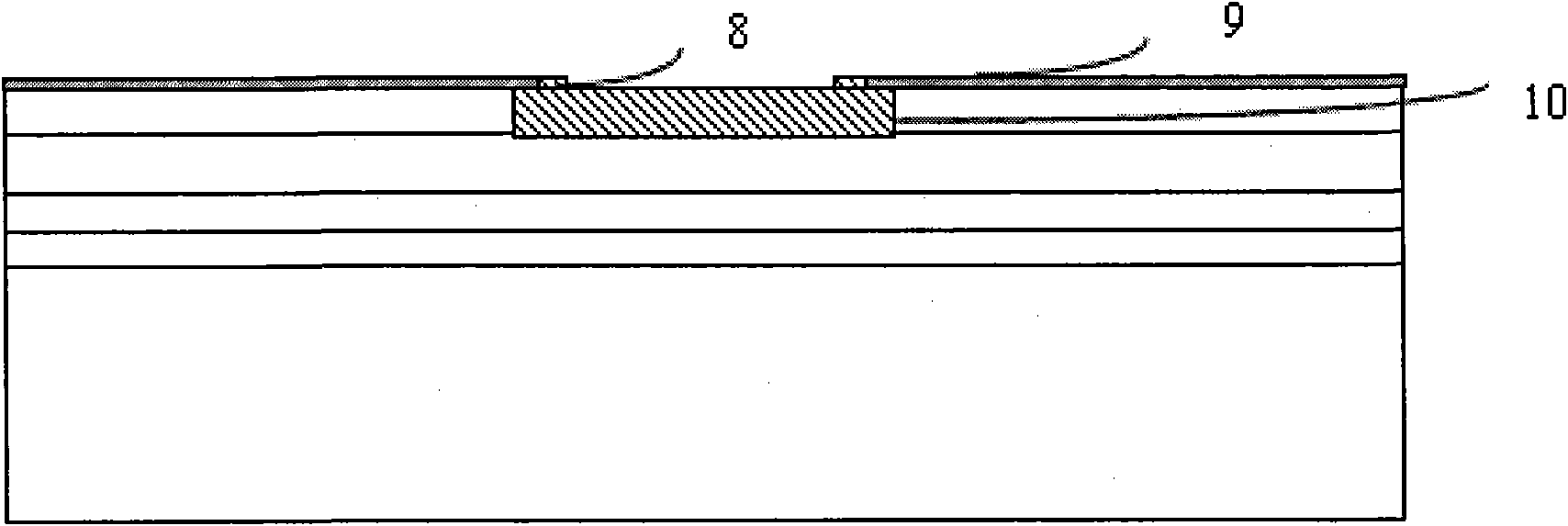

[0036] The present invention adopts the MOCVD epitaxy system to carry out primary epitaxy of the photodiode on the semi-insulating indium phosphide substrate, forms the indium gallium arsenic ohmic contact layer, adopts the gradient diffusion method based on the MOCVD epitaxy system for doping, and adopts reactive ion etching ( RIE) combined with chemical wet etching method to make quasi-mesa, use chemical wet etching method to make the second step, make S i o 2 Passivation layer, making photosensitive surface, evaporation etching electrode, substrate thinning, back sputtering and electrode alloying.

[0037] The present invention will be described in detail below with reference to the accompanying drawings.

[0038] The primary epitaxy of the photodiode is carried out on the semi-insulating indium phosphide substrate by MOCVD method, and the epitaxy is composed of five layers (see figure 1 ), from bottom to top are Fe-doped semi-insulating indium phosphide I substrate 1, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com