Scale and corrosion inhibitor using recycled water as circulating cooling water in fired power plant, method and application thereof

A technology of circulating cooling water, scale and corrosion inhibitor, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc. and other problems, to achieve the effect of excellent corrosion inhibition performance, obvious technical advantages and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The above-mentioned preparation method for reclaimed water as the scale and corrosion inhibitor for circulating cooling water in thermal power plants comprises the following steps:

[0030] Take the components organic phosphonate, polycarboxylic acid multi-polymer, zinc salt, copper corrosion inhibitor and water in proportion;

[0031] Add organic phosphonate, polycarboxylic acid multi-polymer, zinc salt, and water into the reaction kettle, wherein water is the solvent, and stir evenly to obtain the first group of materials; the copper corrosion inhibitor alone is used as the second group of materials;

[0032] Group 1 materials and Group 2 materials are packaged separately.

[0033] The above-mentioned scale and corrosion inhibitors used for reclaimed water as circulating cooling water of thermal power plants are used in the application of thermal power plant circulating cooling water treatment systems. ~50mg / L finished product dosage, the dosage of the second group o...

Embodiment 1

[0049] A scale and corrosion inhibitor (TW-318) used for reclaimed water as circulating cooling water in thermal power plants, containing the following components: organic phosphonate, polycarboxylic acid multi-polymer, copper corrosion inhibitor, zinc salt and Water; water is the solvent, and the copper corrosion inhibitor is added separately.

[0050] 1.1 Material preparation: Strictly follow the formula ratio, weigh the quantitative organic phosphonate, polycarboxylic acid multi-polymer, copper corrosion inhibitor, zinc salt and water in sequence.

[0051] 1.2 Production: Add organic phosphonate, polycarboxylic acid multi-polymer copolymer, zinc salt and water into the reaction kettle, start stirring (80 rpm) to dissolve them all, continue stirring for about 20 minutes, mix well and pack , that is, the present invention; the copper corrosion inhibitor is prepared separately and packaged separately.

Embodiment 2

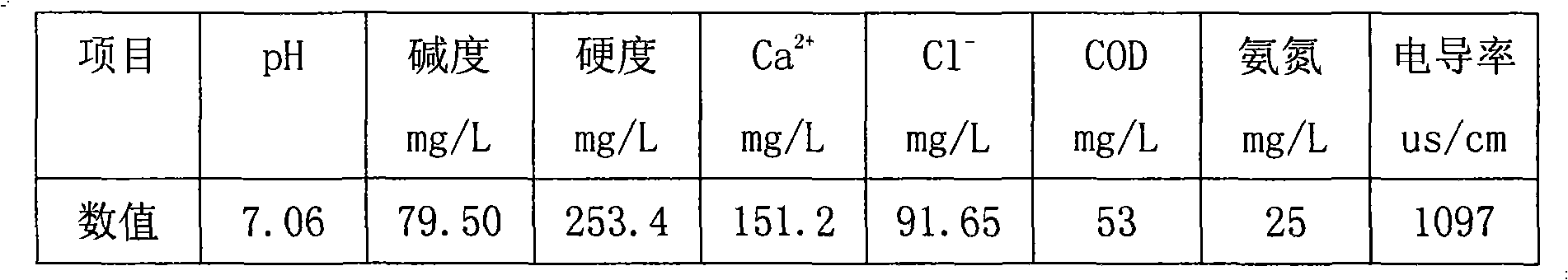

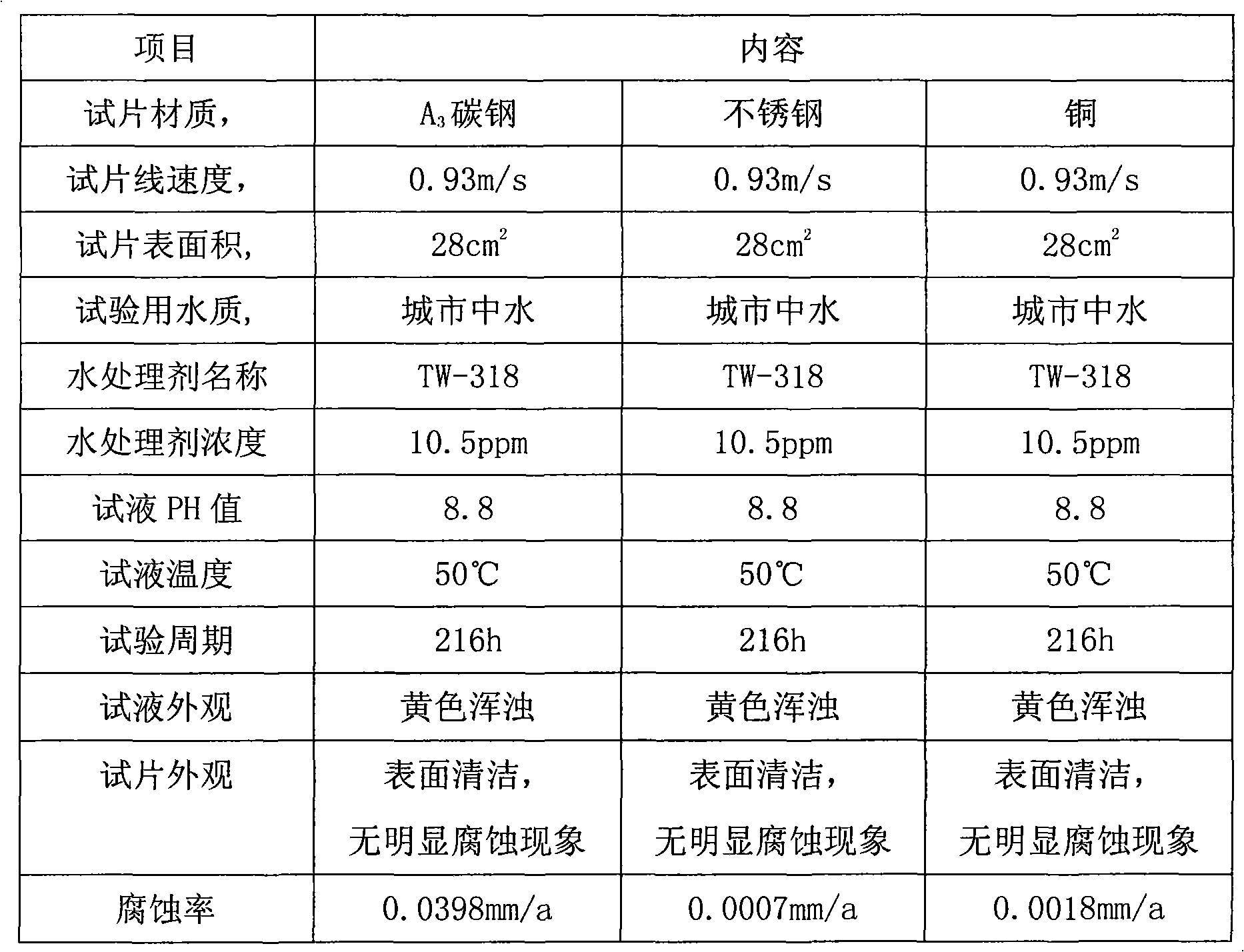

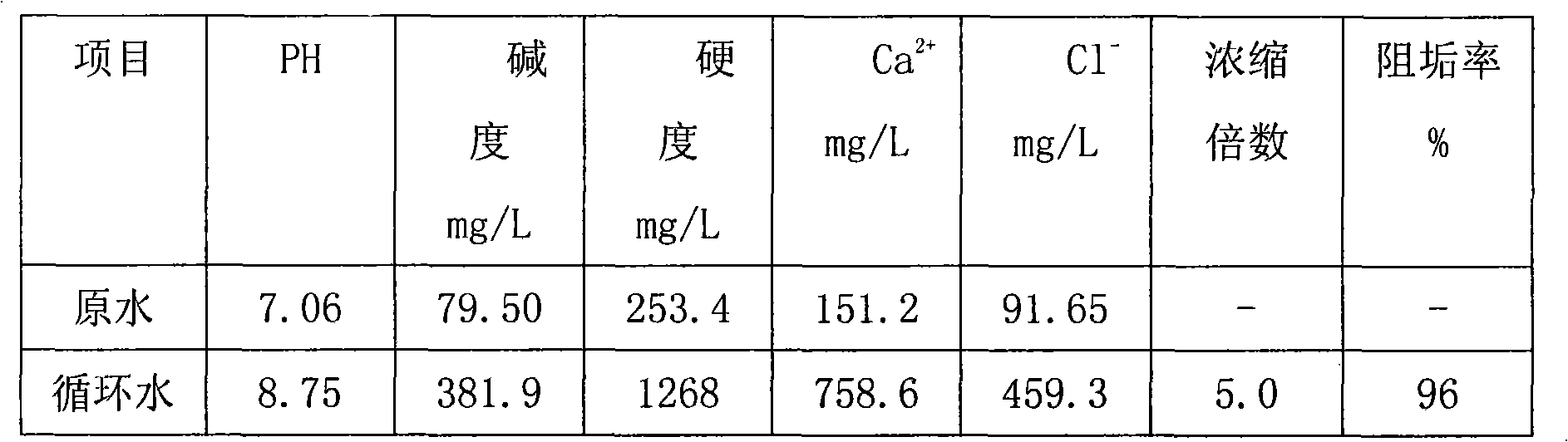

[0053] The antiscaling and corrosion inhibitor used in reclaimed water as circulating cooling water of a thermal power plant according to the invention is tested for reclaimed water corrosion inhibition performance of a sewage treatment plant in Hebei area.

[0054] 2.1 Purpose of the test.

[0055] The method of rotating coupon corrosion test is to evaluate the corrosion inhibition performance of water treatment agent by calculating the corrosion rate and corrosion inhibition rate by using the loss mass of the test piece under the given conditions in the laboratory. The corrosion characteristics of scale and corrosion inhibitors with circulating cooling water as urban reclaimed water are investigated by using the rotating coupon corrosion measurement method, and the indicators such as the change of appearance and color of carbon steel, stainless steel and copper after passing the test, and the corrosion rate measured by the weight loss method are investigated. Comprehensively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com