Preparation method of organic/inorganic nano hybridized magnetic material

A technology of inorganic nano and magnetic materials, applied in the field of organic/inorganic microsphere preparation, can solve the problem of poor controllability, difficult to control the molecular weight and molecular weight distribution of the grafted polymer on the surface of inorganic particles, no active/controllable free radical polymerization, etc. problem, to achieve the effect of smooth surface, good controllability and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

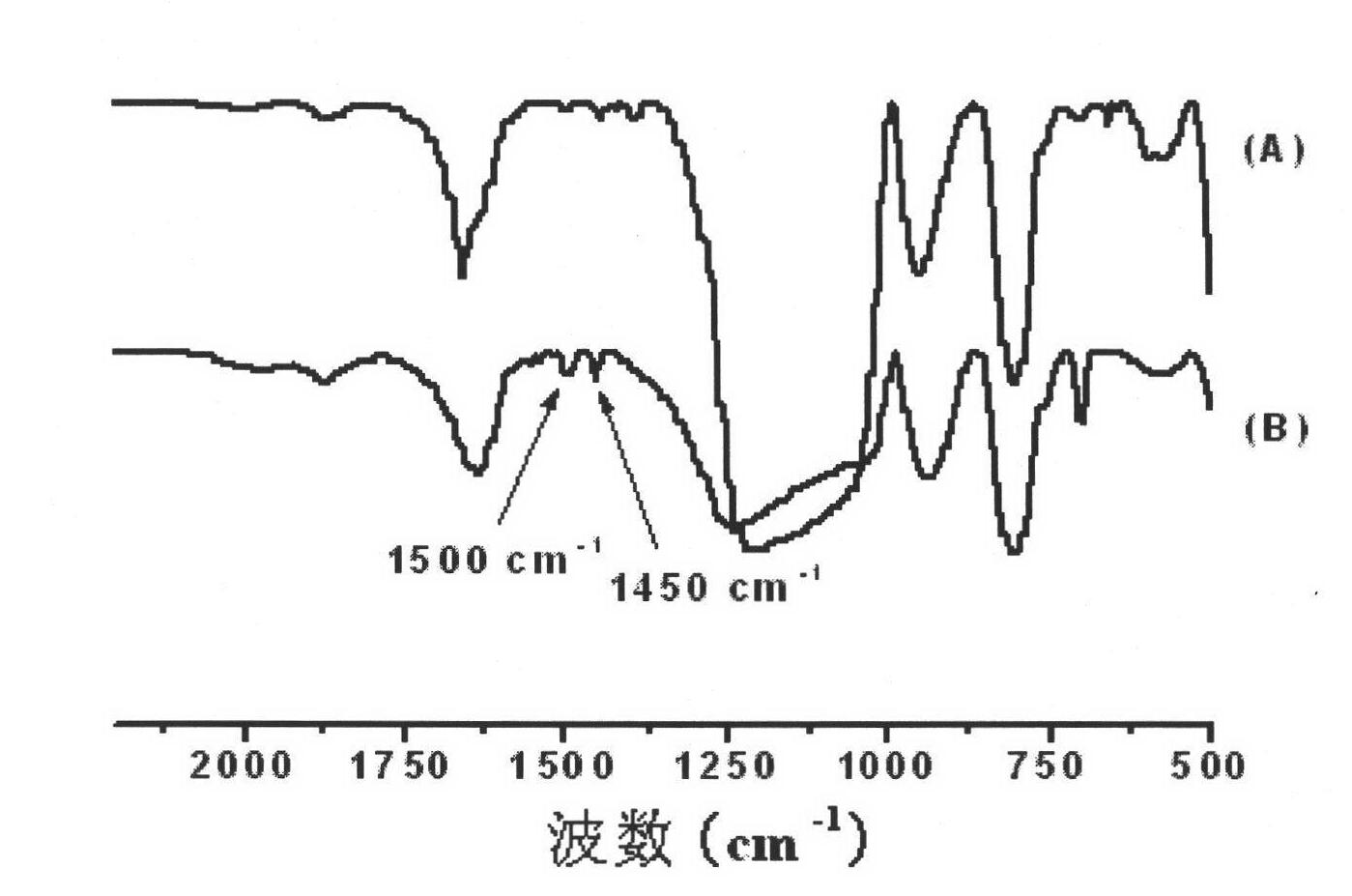

[0030] Example 1: Immobilization of RAFT reagents on the surface of magnetic nanoparticles

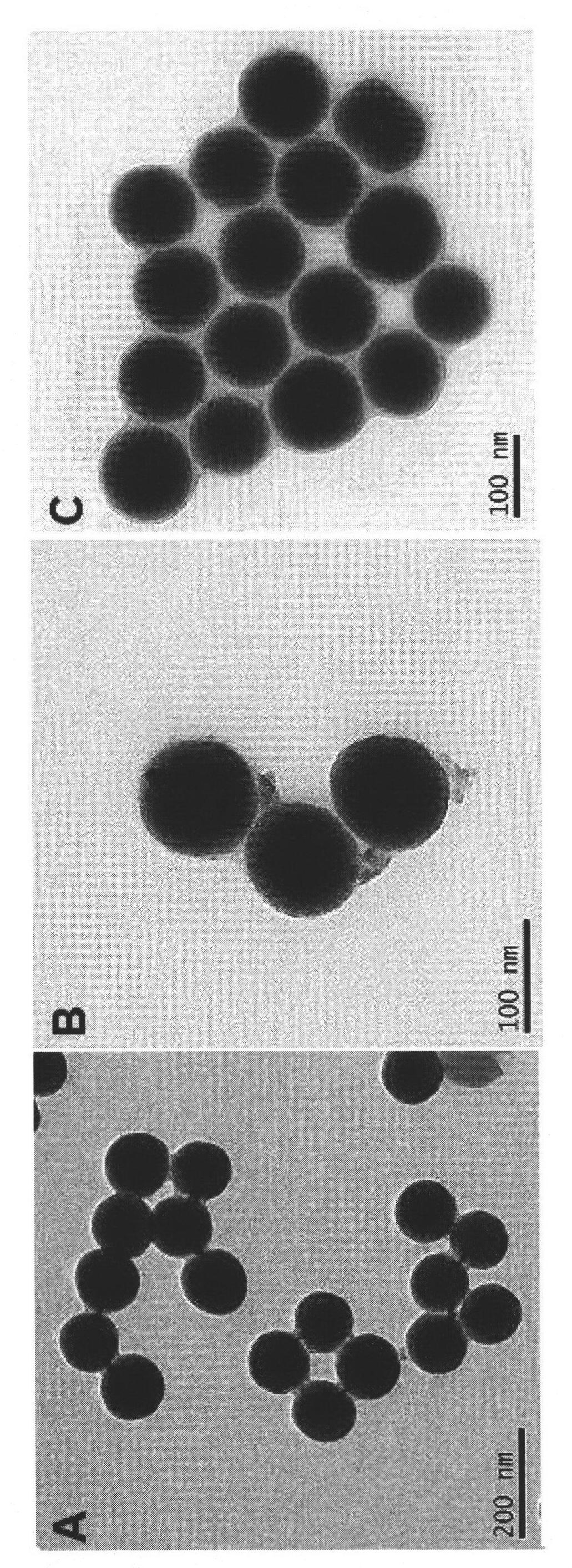

[0031] Synthesis of Magnetic Fe by Co-precipitation 3 o 4 nanoparticles, and then use Hydrolysis of Tetraethyl Orthosilicate to Magnetic Fe 3 o 4 Nanoparticles are encapsulated to form Fe 3 o 4 @SiO 2 core-shell structure.

[0032] Take 1.0g Fe 3 o 4 @SiO 2 Add 0.5 mL of 4-chloromethylphenyltrimethoxysilane to 20 mL of toluene that has been dehydrated and dried at 95 ° C, flow argon for 20 min, reflux for 24 h, and collect by centrifugation. Using a large amount of toluene and acetone for multiple ultrasonic dispersion-centrifugal washing, the chloromethylated product Fe 3 o 4 @SiO 2 -Cl was vacuum-dried at room temperature for use.

[0033] In DMSO (20mL) solution with 0.13g KOH dissolved, add 0.39g carbazole, after stirring for 1h, slowly add 0.2mL C 2 S, after the resulting red solution was stirred at room temperature for 12 hours, the chloromethylated product Fe of th...

Embodiment 2

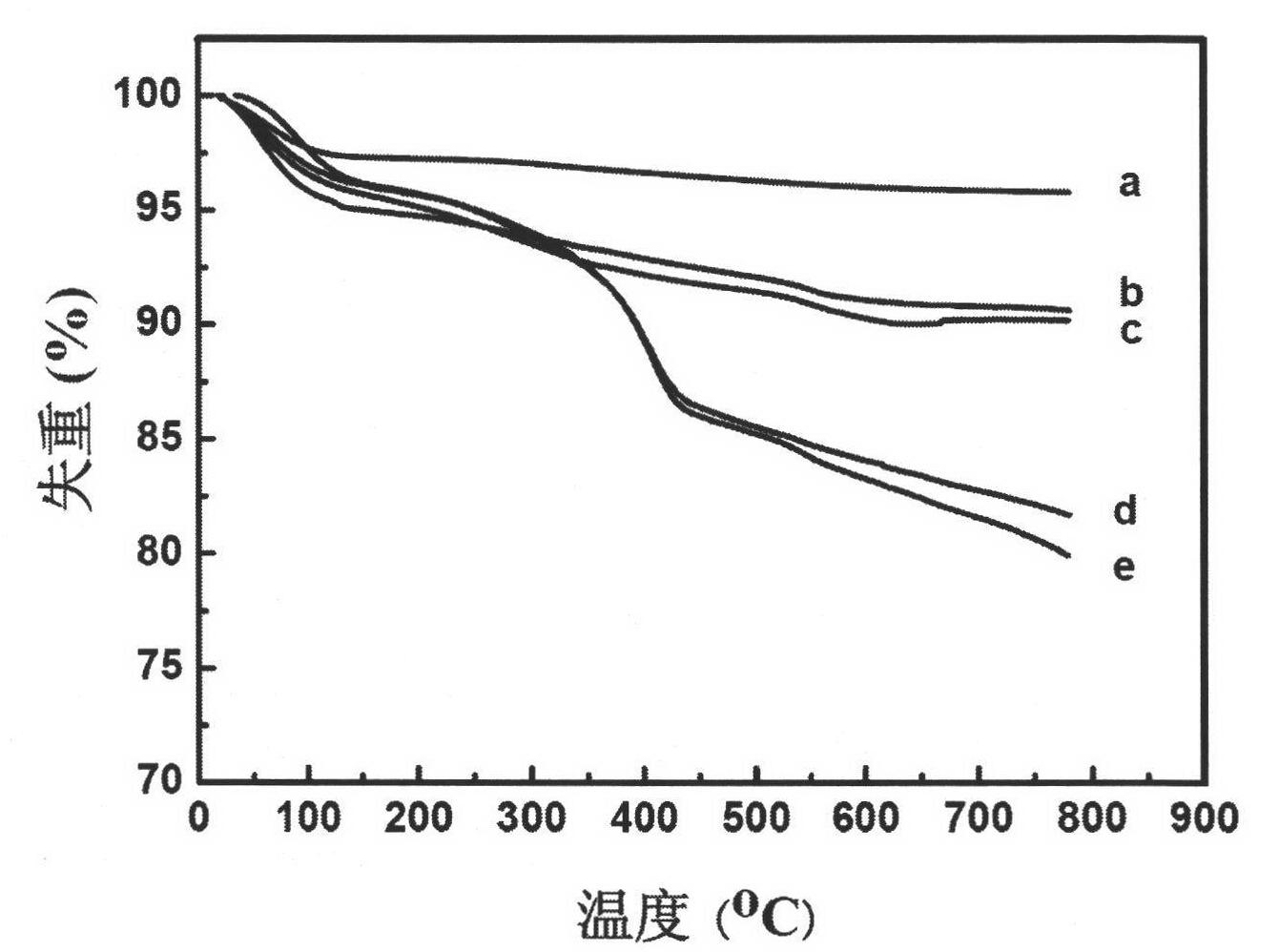

[0034] Embodiment two: soap-free RAFT emulsion graft polymerization synthesis (Fe 3 o 4 @SiO 2 @PSt)

[0035] Add Fe to a 200mL reaction flask 3 o 4 @SiO 2 - BCBD (50 mg), St (0.5 mL, 4.3 mmol), KPS (40 mg, 0.15 mmol), deionized water (50 mL) and a magnetic stirrer. Under ultrasonic conditions, the nanoparticles are uniformly dispersed in water to form a stable white emulsion. It was filled with N 5 times under the condition of constant stirring 2 - Vacuum cycle, finally at N 2 Close the system under atmosphere. The reaction bottle was placed in an oil bath with preset temperature (85°C) for reaction, and after the specified time (12h or 24h), it was cooled to break the emulsification. The product was collected by centrifugation, and the centrifuged product was washed and separated with a large amount of THF: the free PSt precipitate was collected, and the obtained hybrid particles were dried in a vacuum oven for future use.

[0036] The particle size and distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com